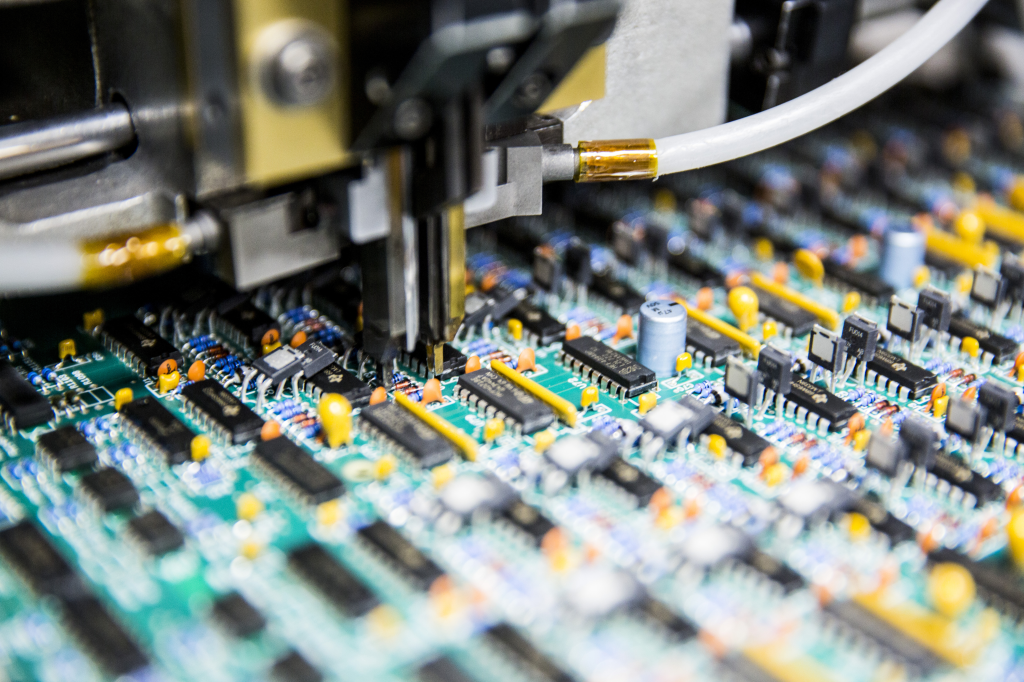

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing a structured platform for connecting and supporting electronic components. The complexity and performance of a PCB are largely determined by its layer structure. Understanding PCB layers is essential for engineers, designers, and anyone involved in electronics manufacturing or prototyping. This guide explores the different types of layers found in PCBs, their specific roles, and how they contribute to the overall functionality and reliability of electronic devices.

For those new to the world of electronics, learning about the construction and purpose of each layer can clarify why PCBs are designed the way they are. If you want to start with the basics, check out this intro to PCB fabrication for foundational knowledge.

The Basics of PCB Layer Structures

At its core, a PCB consists of layers of conductive and insulating materials laminated together. The number of layers can vary from a simple single-sided board to complex multi-layered structures used in advanced electronics. Each layer serves a unique purpose, contributing to the electrical performance, mechanical strength, and manufacturability of the board.

- Single-layer PCBs: Feature one conductive layer and are used in basic, low-cost applications.

- Double-layer PCBs: Have conductive layers on both sides, allowing for more complex routing and component placement.

- Multi-layer PCBs: Consist of three or more conductive layers, separated by insulating materials, enabling high-density and high-speed circuit designs.

Key Functions of Each PCB Layer

To fully grasp understanding PCB layers, it’s important to break down the main types of layers and their individual roles within the board.

Copper Layers: The Heart of Electrical Connectivity

Copper layers are responsible for forming the electrical pathways that connect various components. In single- and double-sided boards, these layers are found on the outer surfaces. In multi-layer PCBs, additional copper layers are sandwiched between insulating materials, allowing for complex circuit routing and improved signal integrity.

- Signal layers: Carry data and control signals between components.

- Power and ground planes: Provide stable voltage references and help reduce electrical noise.

Substrate (Core) Layers: Providing Structure and Insulation

The substrate, often made from fiberglass-reinforced epoxy (such as FR4), acts as the backbone of the PCB. It insulates the copper layers from each other and provides mechanical strength. The choice of substrate material impacts the board’s durability, flexibility, and thermal performance.

Prepreg Layers: Bonding and Insulation in Multi-layer Boards

In multi-layer PCBs, prepreg (pre-impregnated bonding sheets) is used to bond copper and core layers together. Prepreg provides electrical insulation and ensures the layers remain securely laminated during manufacturing. Its properties influence the board’s thickness and dielectric characteristics.

Protective and Functional Outer Layers

The outermost layers of a PCB serve both protective and functional roles, ensuring the board’s longevity and reliability in various environments.

Solder Mask: Shielding and Defining Pads

The solder mask is a thin polymer layer applied over the copper traces, except for the areas where components will be soldered. Its main functions include:

- Preventing accidental solder bridges between closely spaced pads.

- Protecting copper traces from oxidation and environmental damage.

- Enhancing the board’s appearance, typically with a green, blue, or red finish.

Silkscreen Layer: Marking and Identification

The silkscreen is a printed layer that adds component labels, logos, and other markings to the board. This layer is crucial for assembly, troubleshooting, and maintenance, as it guides technicians in identifying component locations and orientations.

Surface Finish: Ensuring Reliable Connections

The exposed copper pads on a PCB are coated with a surface finish to prevent oxidation and ensure good solderability. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservatives). The choice of finish affects both the manufacturing process and the board’s performance in its final application.

Layer Stack-Up and Its Impact on Performance

The arrangement of layers, known as the stack-up, is a critical aspect of PCB design. A well-planned stack-up can minimize electromagnetic interference, improve signal integrity, and support high-speed data transmission. Designers must balance electrical requirements, mechanical constraints, and cost considerations when determining the optimal layer configuration.

For a deeper dive into the manufacturing process and how different layers are fabricated, you might find this resource on electronics fabrication basics helpful.

Choosing the Right Layer Count for Your Application

The decision between single, double, or multi-layer PCBs depends on the complexity of the circuit, space constraints, and performance requirements. Simple devices like calculators or remote controls often use single-layer boards, while smartphones, computers, and industrial equipment require multi-layer designs to accommodate dense circuitry and high-speed signals.

- Single-layer: Cost-effective, easy to manufacture, suitable for basic circuits.

- Double-layer: Offers more routing options, supports moderate complexity.

- Multi-layer: Essential for advanced electronics, high-speed, and high-frequency applications.

The choice of layer count also impacts manufacturing costs, lead times, and the board’s ability to handle power and thermal loads. For a comprehensive overview of the electronics production process, refer to this ultimate guide to electronics manufacturing.

Common Challenges in Multi-Layer PCB Design

As the number of layers increases, so do the challenges in design and fabrication. Some common issues include:

- Signal integrity: Crosstalk and electromagnetic interference can degrade performance if layers are not properly arranged.

- Thermal management: Dense layer stacks can trap heat, requiring careful planning of power and ground planes.

- Manufacturing complexity: More layers mean tighter tolerances and increased risk of defects during lamination and drilling.

Addressing these challenges requires collaboration between designers, manufacturers, and assembly teams. Staying updated on hardware design trends and innovations can help teams adopt best practices and leverage new materials or techniques.

Frequently Asked Questions

What is the main purpose of having multiple layers in a PCB?

Multiple layers allow for more complex circuit designs by providing additional routing space for signal traces, power, and ground planes. This enables higher component density, improved signal integrity, and better performance in advanced electronic devices.

How do I choose the right number of layers for my PCB project?

The ideal number of layers depends on the circuit’s complexity, required signal integrity, available space, and budget. Simple circuits may only need one or two layers, while high-speed or high-density applications typically require four or more layers to meet performance and reliability standards.

What are the risks of poor PCB layer stack-up design?

An improperly designed stack-up can lead to signal interference, excessive electromagnetic emissions, thermal issues, and manufacturing defects. Careful planning of layer arrangement and material selection is crucial for ensuring the board’s reliability and performance.

For those interested in the step-by-step process of how electronics are built, the how electronics are manufactured article provides additional insights.

In summary, a solid grasp of understanding PCB layers is fundamental for anyone involved in electronics design or production. By knowing the function and importance of each layer, you can make informed decisions that lead to more reliable, efficient, and innovative electronic products.