The demand for faster and more efficient electronic devices shows no signs of slowing down. Hailed as a revolutionary advancement, Optical Interconnect in PCBs is paving the way for a new realm of possibilities in technology. This innovation promises to transform how signals traverse complex circuits, leading to significant enhancements in performance, speed, and thermal management.

In this article, aimed at providing insights to both exporters and importers, we will delve into the mechanisms that make optical interconnects a game-changer in the world of Printed Circuit Boards (PCBs).

Introduction to Optical Interconnect in PCBs

The integration of optical interconnects into PCBs represents a quantum leap in circuit design. By allowing signals to be transmitted through light rather than electrical currents, these systems reduce parasitic capacitance and inductance, two primary sources of signal degradation in traditional circuits.

Historical Background

While the concept of using light to transmit data isn’t new, translating it into effective pathways within PCBs required years of research and innovation. This journey began as engineers sought to overcome the limitations posed by copper-based interconnects.

The Importance for the Export-Import Sector

For those in the import-export industry, the adoption of optical interconnect technology could mean faster shipments, more efficient production cycles, and, ultimately, a competitive edge in the market. As demand for more sophisticated devices surges globally, understanding these advancements becomes crucial.

Benefits of Optical Interconnect Technologies

The primary advantages derive from the inherent properties of light. These include reduced signal distortion, higher bandwidth capacity, and improved thermal efficiency. The move from electrical to optical systems reduces energy consumption, resulting in greener electronic solutions. To learn more about sustainable electronics, visit greener future in manufacturing.

Reduced Signal Distortion

Conventional PCBs often face challenges with cross-talk and signal degradation over distance. Optical interconnects substantially mitigate these issues due to their high immunity to electromagnetic interference.

Higher Data Bandwidth

Optical fibers can carry significantly more data than conventional copper wires. With technology pushing for increased data rates, optical solutions are not just preferred but necessary. These advancements correlate well with tools utilized in circuit simulation tools.

Applications in Modern Electronics

From telecommunications to computing, the integration of optical interconnects in PCBs is transforming diverse sectors. Manufacturers are eager to integrate these systems to improve device capability and reduce size and cost.

Telecommunications

Given their need for rapid data transmission, telecom companies are at the forefront of optical interconnect integration. This technology simplifies infrastructure, reduces latency, and enhances network capacity.

Computing

In data centers, the need for quick, reliable data transfer is critical. Optical solutions aid in maintaining high speeds and reliability, driving improvements in cloud computing and big data analytics.

Challenges and Future Directions

While promising, there are challenges associated with implementing optical interconnects within PCBs. These include costs, fabrication complexities, and standardization. However, continued research and development offer a hopeful outlook for overcoming these hurdles.

Cost Implications

The initial investment in optical technology can be substantial. However, the long-term benefits in terms of efficiency and capability generally outweigh the initial expenses.

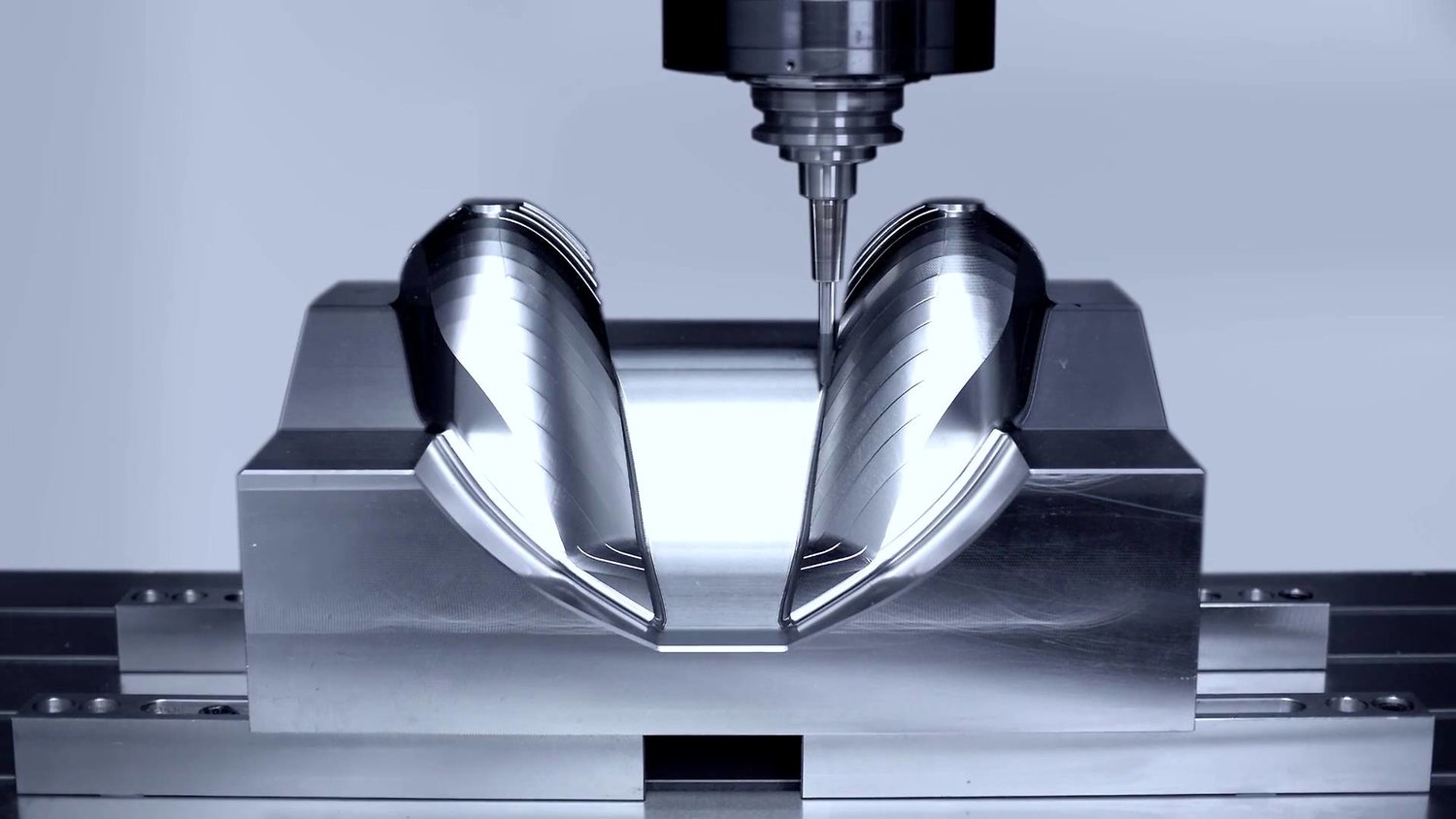

Fabrication Complexities

Integrating optical components within traditional PCB designs requires specialized knowledge and technology. Nonetheless, companies are rapidly developing solutions to streamline this process.

Conclusion

The evolution of optical interconnect in PCBs exemplifies the relentless pursuit of performance enhancements within the electronics industry. Its potential to transform various applications is enormous, offering craftily-designed electronics with reduced environmental impact and improved functionalities. For a deeper dive into electronics advancements, Yales’ electronics prototyping offers valuable insights.

FAQ Section

What is the primary benefit of using optical interconnects?

Using optical interconnects significantly reduces signal distortion and enhances data transmission speeds, leading to more efficient electronic components.

How does optical interconnect technology impact manufacturing?

By simplifying circuit design and enabling high-speed data transfer, optical technology can reduce manufacturing time and costs, as discussed in detail in related custom electronics manufacturing.

Are there any long-term cost benefits?

Although initial adoption may be expensive, the efficiency, speed, and reduced energy consumption lead to long-term savings and environmental benefits, reflecting insights shared in the supply chains game.