Surface Mount Technology (SMT) has revolutionized the way electronic devices are produced, enabling faster, more reliable, and compact circuit assemblies. Understanding how SMT assembly works is essential for anyone involved in electronics design, manufacturing, or quality assurance. This guide breaks down the core steps, equipment, and considerations that define modern SMT processes, providing a practical overview for engineers, procurement specialists, and electronics enthusiasts.

If you’re new to the world of circuit production, you may also find value in our intro to PCB fabrication, which covers foundational concepts that complement the SMT assembly process described here.

Understanding Surface Mount Technology in Electronics

SMT is a method where electronic components are mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole techniques, which require leads to be inserted into drilled holes, SMT components are placed on pads and soldered in place. This approach allows for higher component density, improved electrical performance, and greater automation in manufacturing.

The adoption of SMT has enabled the miniaturization of consumer electronics, industrial controls, and medical devices. It also supports automated production lines, reducing labor costs and improving consistency.

Key Steps in the SMT Assembly Process

To fully grasp how SMT assembly works, it’s helpful to break down the process into its main stages. Each step is critical to ensuring the reliability and performance of the final electronic product.

Solder Paste Application

The process begins with the application of solder paste to the PCB. Solder paste, a mixture of powdered solder and flux, is deposited onto the board using a stencil that matches the layout of the component pads. Accurate paste deposition is vital, as it determines the quality of the solder joints formed during reflow.

Component Placement

After solder paste is applied, pick-and-place machines position surface mount components onto the board. These machines use high-speed vision systems and precision nozzles to place resistors, capacitors, integrated circuits, and other parts exactly where they are needed. The automation of this step ensures repeatability and reduces the risk of human error.

Reflow Soldering

Once components are in place, the assembly moves through a reflow oven. The oven heats the board in a controlled manner, melting the solder paste and forming strong electrical and mechanical connections between the components and the PCB pads. Proper temperature profiling is essential to prevent defects such as solder bridges or cold joints.

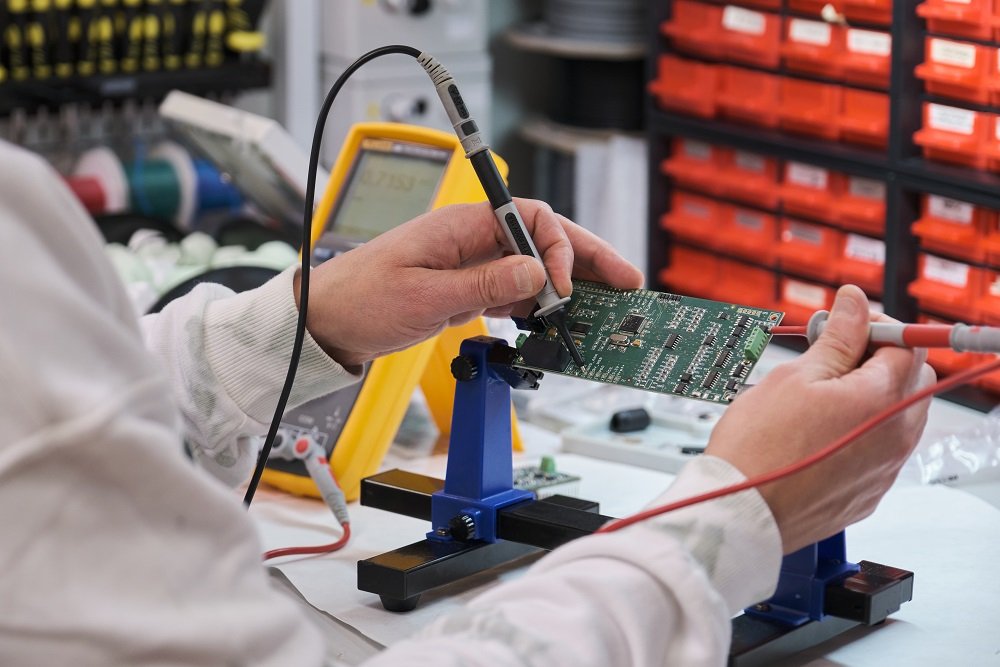

Inspection and Quality Control

Inspection follows soldering and is crucial for detecting issues early. Automated Optical Inspection (AOI) systems scan the boards for misaligned components, soldering defects, and missing parts. For complex assemblies, X-ray inspection may be used to check hidden solder joints, especially for components like BGAs (Ball Grid Arrays).

Testing and Final Assembly

Functional testing ensures that the assembled circuit performs as intended. This may involve in-circuit testing (ICT), flying probe tests, or custom functional testers. After passing all tests, the boards move to final assembly, where they may be integrated into enclosures or combined with other subassemblies.

Equipment Used in Modern SMT Lines

The efficiency and accuracy of SMT assembly depend heavily on specialized equipment. Here are the core machines found in a typical SMT production line:

- Stencil Printer: Applies solder paste to the PCB using a stainless steel stencil.

- Pick-and-Place Machine: Automatically positions components on the board with high speed and precision.

- Reflow Oven: Heats the assembly to melt solder and form reliable joints.

- AOI System: Inspects boards for placement and soldering defects.

- X-ray Inspection: Used for complex or high-density boards to check hidden solder joints.

- Conveyor Systems: Move assemblies between each stage efficiently.

The integration of these machines enables high-volume, consistent production, which is essential for today’s electronics industry.

Advantages of SMT in Electronics Production

The shift to SMT has brought several benefits to electronics manufacturing:

- Miniaturization: Enables smaller, lighter devices by allowing components to be mounted on both sides of the PCB.

- Increased Reliability: Automated processes reduce human error and improve solder joint consistency.

- Cost Efficiency: High-speed assembly lines lower labor costs and increase throughput.

- Design Flexibility: Supports complex, multi-layer designs for advanced applications.

For a deeper dive into the broader context of electronics manufacturing, you might be interested in our electronics fabrication basics article, which covers related processes and terminology.

Challenges and Best Practices in SMT Assembly

While SMT offers many advantages, it also presents challenges. Solder paste quality, stencil cleanliness, and precise machine calibration are all critical factors. Component storage and handling must prevent moisture absorption and electrostatic discharge. Regular maintenance of equipment and ongoing staff training help maintain high yields and product quality.

Traceability is another important aspect. Modern SMT lines often include barcode or RFID tracking to monitor each board’s journey through production. This supports quality control, regulatory compliance, and rapid troubleshooting if issues arise.

For those interested in the upstream processes that enable SMT, the semiconductor fabrication process guide provides a comprehensive look at how chips are made before they reach the assembly line.

Frequently Asked Questions

What is the main difference between SMT and through-hole assembly?

The primary distinction is that SMT mounts components directly onto the surface of the PCB, while through-hole assembly requires leads to be inserted into holes and soldered on the opposite side. SMT allows for higher component density and is better suited for automated, high-volume production.

How does SMT assembly impact product reliability?

Automated placement and soldering in SMT lines reduce the risk of human error, resulting in more consistent and reliable connections. Additionally, SMT components are less susceptible to mechanical stress, which can improve long-term durability.

Can SMT be used for prototyping as well as mass production?

Yes, SMT is suitable for both prototyping and large-scale manufacturing. Many contract manufacturers offer quick-turn SMT assembly services for prototypes, allowing designers to test and iterate before moving to full production.

To learn more about the step-by-step journey from concept to finished device, see our guide on how electronics are manufactured.