Electronic enclosure design refers to the process of creating protective casings for electronic devices. These enclosures serve as shields against environmental factors, ensuring the safety and functionality of electronic components. A well-thought-out design can make a significant difference in product performance and durability.

Why is Electronic Enclosure Design Important?

For both exporters and importers, understanding the importance of electronic enclosure design is crucial. It not only impacts the physical protection of the device but also affects aesthetics and user interface, which are vital for market success.

Key Considerations in Electronic Enclosure Design

- Material Selection: Choosing the right material is essential for ensuring durability and protection against elements such as dust, heat, and moisture.

- Thermal Management: Proper thermal regulation is necessary to prevent overheating and ensure the smooth functioning of electronics.

- EMI Shielding: Avoiding electromagnetic interference requires specific designs to shield sensitive components.

Materials Used in Electronic Enclosure Design

The selection of materials in electronic enclosure design plays a pivotal role in protecting and maintaining the functionality of an electronic device. Each material offers different benefits based on the specific requirements of the product.

Common Materials

Plastics: Known for their lightweight and cost-effectiveness, plastic enclosures are commonly used for consumer electronics.

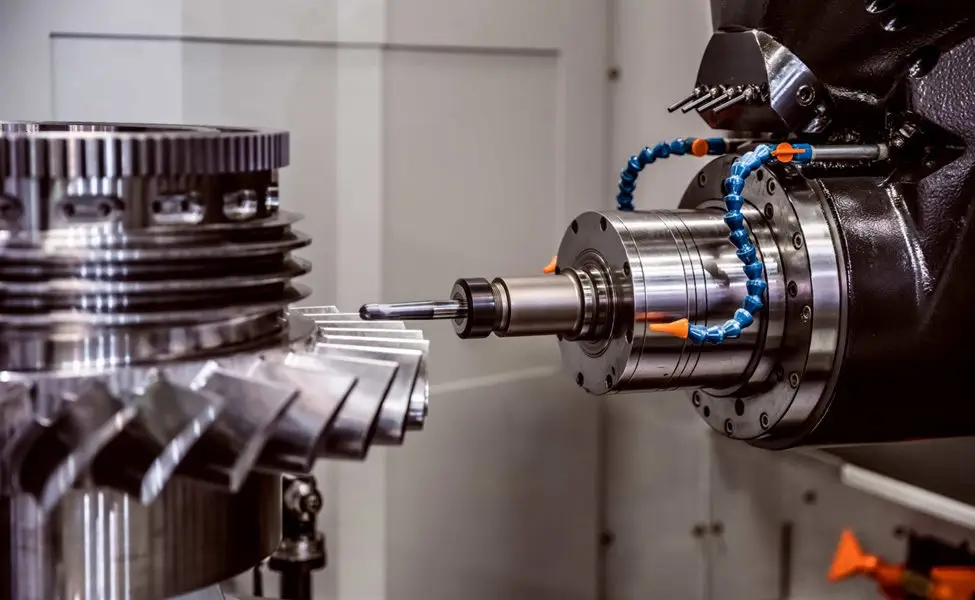

Metals: Aluminum and stainless steel offer excellent protection and thermal dissipation, often used in industrial applications.

Designing for Manufacturability

Exporters and importers should prioritize the manufacturability of electronic enclosures to streamline production and reduce costs. Simple yet effective designs can prevent delays and manufacturing errors.

Design Tips

- Simplify the design to minimize parts and assembly time.

- Ensure components are easily accessible for assembly and maintenance.

For more insights on how smart manufacturing is changing the game, read our article on Future of Supply Chains.

Prototyping in Electronic Enclosure Design

Prototyping remains a critical step within the electronic enclosure design process. Through the development of physical prototypes, designers can test different aspects of their enclosures, including fit, form, and function, before committing to mass production.

Benefits of Prototyping

- Identifying flaws in the design early, saving costs.

- Ensuring the product meets safety and performance standards.

Learn about tools driving innovation in our article on Circuit Simulation Tools.

Sustainability in Electronic Enclosure Design

Sustainability is becoming increasingly important in electronic enclosure design. Environmentally friendly designs, using recyclable materials and energy-efficient manufacturing processes, are beneficial for both the earth and your business’s reputation.

Sustainable Practices

- Opt for biodegradable or recyclable materials.

- Implement energy-saving measures in production.

Explore how electronics manufacturing is getting greener in our Sustainable Electronics article.

Challenges in Electronic Enclosure Design

Designers face several challenges when it comes to electronic enclosure design. These include balancing aesthetics with robustness, integrating the latest technologies, and adhering to various compliance standards.

Regulatory Compliance

Understanding and meeting international standards and regulations is crucial for ensuring product viability in global markets. For further information on prototyping, visit electronic prototyping.

Emerging Trends in Electronic Enclosure Design

As technology evolves, so does electronic enclosure design. Current trends include the integration of smart features, advanced materials, and increased automation in the design and production process.

Industry Innovations

Read about how custom electronics are driving innovation in our article on Custom Electronics Manufacturing.

Questions to Ask When Designing an Electronic Enclosure

To ensure success in electronic enclosure design, exporters and importers should ask specific questions early in the process. This will guide the project toward a functional and appealing end-product.

Important Questions

- What is the primary function of the enclosure?

- Which environmental conditions will it face?

The Future of Electronic Enclosure Design

The future of electronic enclosure design holds exciting prospects, with innovations driven by advances in material science, smart manufacturing, and sustainable practices. As these developments continue to unfold, businesses must stay informed and adaptable to maintain a competitive edge.

Adapting to Change

Continuous learning and adaptation will be key for any business looking to excel in the field of electronic design. Embracing new technologies and methodologies can not only improve product quality but also enhance market success.

Conclusion

In conclusion, electronic enclosure design is a multifaceted process requiring careful consideration of materials, design, manufacturing, and environmental impact. By staying attuned to industry trends and priorities, businesses can create effective and sustainable electronic enclosures that meet international standards and consumer expectations.

FAQs

What materials are best for electronic enclosure design?

Common materials include plastics for lightweight applications and metals like aluminum for heavy-duty environments.

How does thermal management affect electronic enclosures?

Thermal management is crucial to prevent overheating and maintain optimal performance in devices.

Are there sustainable practices in electronic enclosure design?

Yes, using recyclable materials and eco-friendly production methods can make designs more sustainable.