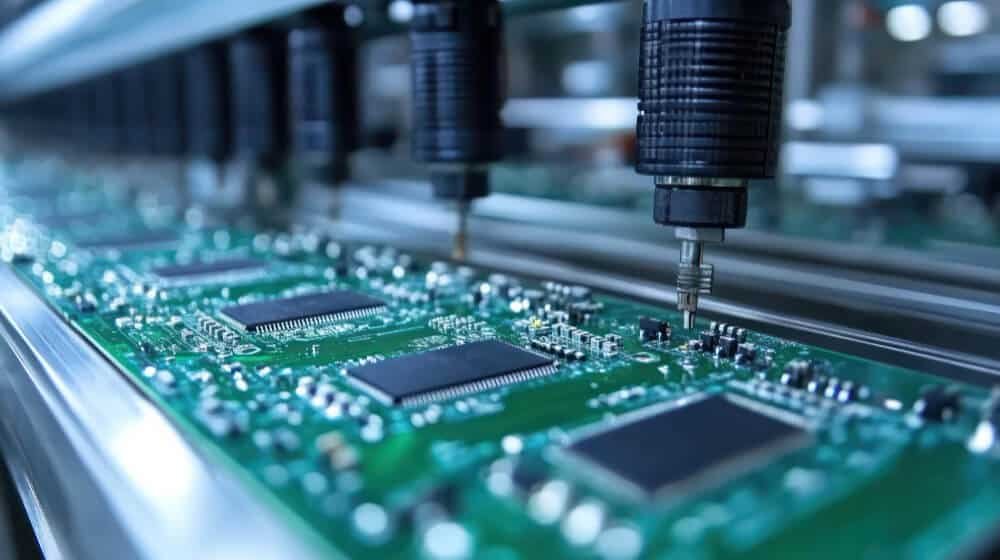

As the world of technology continues to evolve, so does the need for innovative solutions. One area that is seeing significant growth is mechanical prototyping. This process involves the creation of physical models or prototypes from a design concept. It’s an essential step in the product development process, allowing engineers and designers to test and refine their ideas before moving into production. In this article, we will delve into the various techniques used in mechanical prototyping.

For a more comprehensive understanding of the entire product design process, you may want to check out our guide on the hardware product design workflow.

Mechanical Prototyping Techniques

The techniques used in mechanical prototyping can vary widely depending on the specific project requirements. However, some common methods include:

Choosing the Right Technique

Selecting the appropriate prototyping technique depends on several factors, including the complexity of the design, the materials being used, and the intended functionality of the prototype. Each method has its advantages and limitations, and it’s crucial to understand these before deciding on a particular approach.

Importance of Mechanical Prototyping

Mechanical prototyping plays a crucial role in product development. It allows for testing and validation of design concepts, identification of potential issues, and refinement of the design before moving into production. This can save significant time and resources, reducing the risk of costly errors later in the process. For more insights on this topic, you can visit this descriptive anchor text.

Written by Ethan Carter