Electromagnetic interference (EMI) and electromagnetic susceptibility (EMS) compliance are crucial aspects of hardware design and manufacturing. Understanding their significance can help optimize product performance, ensure safety, and meet regulatory requirements. This article will delve into the essence of EMI/EMS compliance in the hardware industry.

Before we delve deeper, it’s worth noting the relevance of this topic in the broader field of hardware design. For more insights on this, you can explore our article on hardware prototyping for robotics.

Understanding EMI and EMS

EMI refers to the disruption of an electronic device’s operation due to an external source of electromagnetic energy. EMS, on the other hand, is the degree to which a device can withstand and operate correctly in an electromagnetic environment.

Why EMI/EMS Compliance Matters

Compliance with EMI/EMS standards is essential for several reasons. It ensures the safety and reliability of electronic devices, prevents interference with other devices, and complies with international regulations. Non-compliance can lead to product recalls, legal issues, and damage to the company’s reputation.

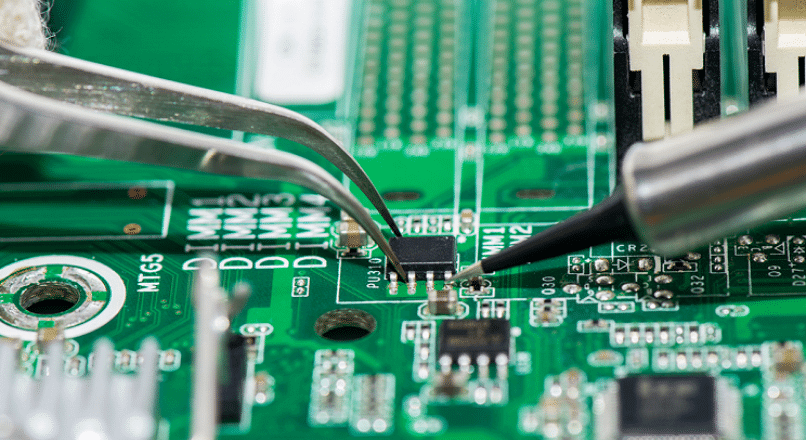

EMI/EMS Compliance in Hardware Design

Compliance begins at the design stage. Engineers must consider EMI/EMS factors when designing hardware to minimize electromagnetic interference and enhance the product’s electromagnetic compatibility.

For more insights on hardware design, you can visit this descriptive anchor text.

Conclusion

EMI/EMS compliance is not just about meeting regulatory requirements. It’s about ensuring the safety, reliability, and performance of electronic devices. By understanding and prioritizing EMI/EMS compliance, hardware manufacturers can deliver high-quality products that stand the test of time.

Author: Ethan Carter

Publication Date: 2025-11-12