Creating a successful hardware product requires a well-defined and effective workflow. This process, often referred to as the hardware product design workflow, is a systematic approach to transforming an idea into a tangible, market-ready product. This methodology helps ensure that the final product meets the desired quality standards and fulfills its intended purpose.

Understanding the importance of tolerances in hardware design is crucial in this process. Now, let’s explore the steps involved in this workflow.

Conceptualizing the Product Idea

The first step in the hardware product design workflow is conceptualizing the product idea. This involves identifying a problem that the product will solve and defining its key features and specifications.

Design and Development

Once the concept is clear, the next step is the design and development phase. This involves creating detailed design documents, developing prototypes, and testing them for functionality and performance.

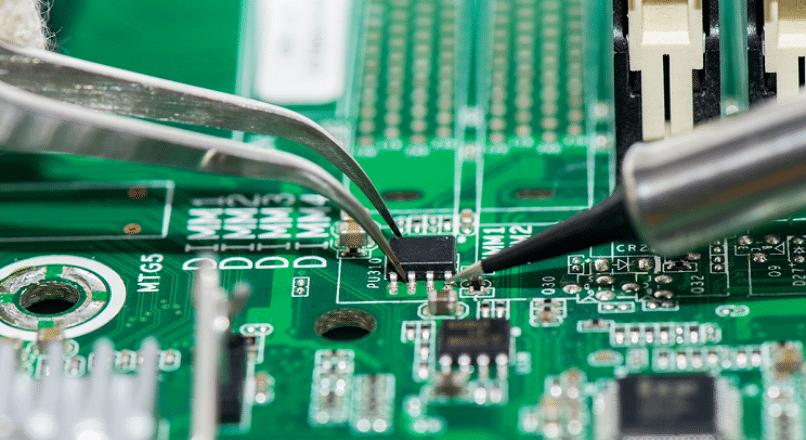

Manufacturing and Assembly

After the design and development phase, the product goes into manufacturing. This involves producing the hardware components, assembling them, and testing the assembled product.

Quality Assurance and Testing

The final step in the workflow is quality assurance and testing. This ensures that the product meets the required quality standards and is ready for launch.

For a deeper dive into a specific aspect of this process, you can explore how to prototype hardware products with a Raspberry Pi on this external resource.

The hardware product design workflow is a complex process that requires careful planning and execution. However, with the right approach, it can lead to the creation of innovative and successful products.