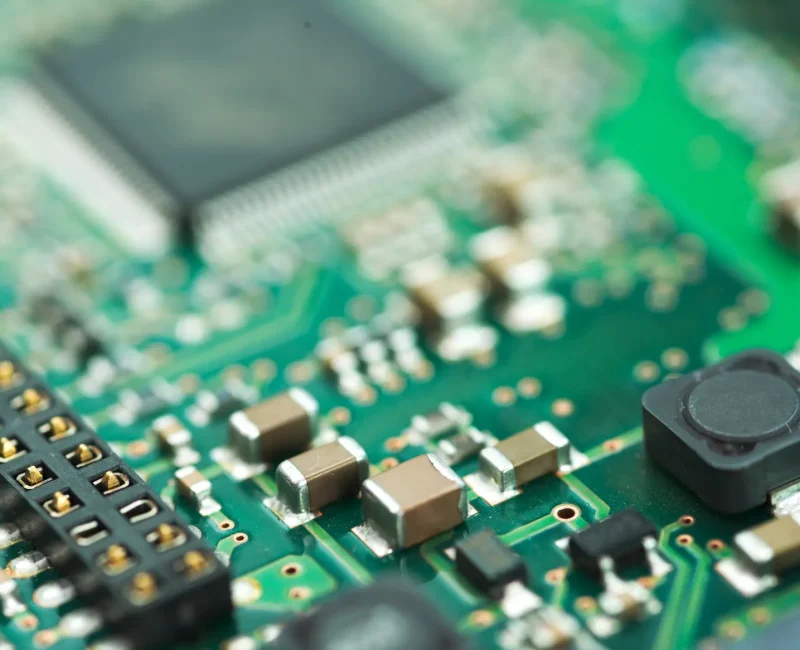

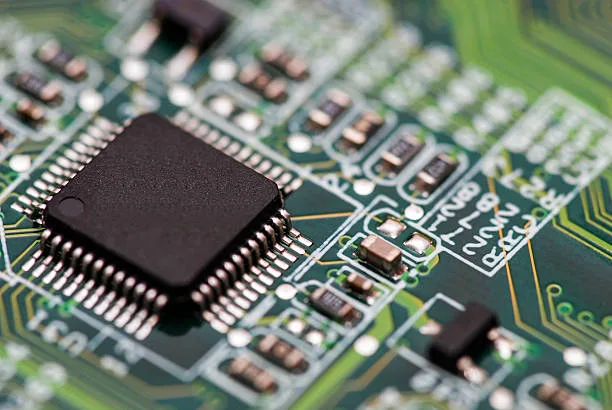

When it comes to the production of electronic devices, the harmony between hardware design and manufacturing processes is a critical aspect. This article explores how these two crucial elements can be aligned for optimal results.

For a deeper understanding of the basics of hardware design, you might want to check out our Beginner’s Guide to Prototyping Microcontroller Systems.

Understanding the Importance of Alignment

The alignment between hardware design and manufacturing processes is essential to ensure efficient production. It helps in reducing errors, improving product quality, and speeding up the time-to-market.

Strategies for Achieving Alignment

There are several strategies that can be employed to achieve alignment between hardware design and manufacturing processes. These include early engagement with manufacturers, use of design for manufacturing (DFM) principles, and adoption of agile methodologies.

Challenges in Aligning Design and Manufacturing

Despite its importance, achieving alignment between hardware design and manufacturing can be challenging. Some of the common obstacles include communication gaps, lack of understanding of manufacturing constraints, and rapidly changing technology landscapes.

For more insights on hardware prototyping, you can visit this descriptive anchor text.

In conclusion, aligning hardware design with manufacturing processes is a crucial aspect of electronic device production. It not only ensures efficient production but also contributes to product quality and speed to market.