Transforming an idea into a tangible product involves a series of steps, each crucial in its own right. This process, often referred to as the “concept to prototype workflow,” is a journey that requires a deep understanding of design principles, prototyping techniques, and testing methodologies. In this article, we will delve into this workflow, shedding light on each phase and providing insights on how to navigate them effectively.

Before we get into details, it’s worth mentioning that if you’re new to hardware engineering, you might find our guide on hardware engineering basics useful.

Initial Conceptualization and Design

The journey from idea to tangible product begins with conceptualization. This phase involves brainstorming, research, and sketching out the initial design of the product. It’s a critical stage where the product’s functionality, aesthetics, and feasibility are determined.

Prototyping and Refinement

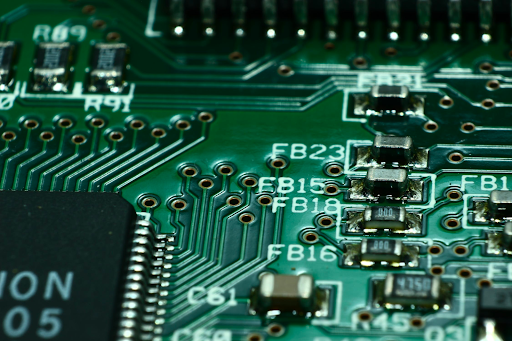

Once the design is finalized, the next step is prototyping. This phase involves creating a physical model of the product to test its functionality and design. It’s during this stage that any flaws or areas of improvement are identified and addressed.

Testing and Finalization

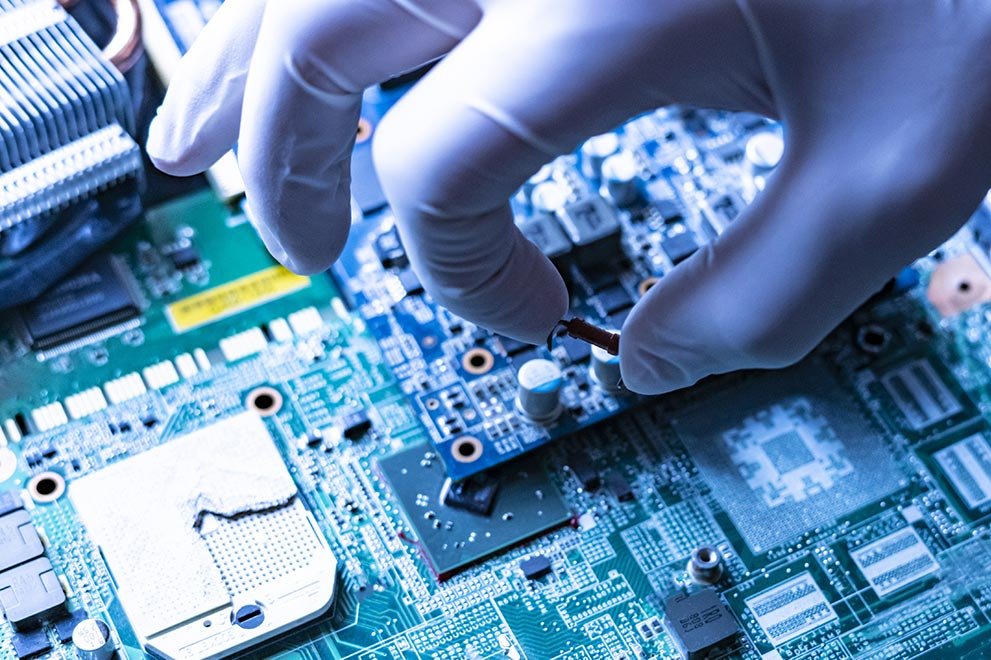

The final stage in the workflow is testing. This involves rigorous evaluation of the prototype to ensure it meets all the required standards and specifications. Once testing is complete, the prototype is finalized and ready for mass production.

The journey from concept to prototype is a complex one, but with a clear understanding of the workflow, it becomes manageable. For more insights on rapid prototyping, check out this comprehensive guide.

By Ethan Carter, Published on 2025-10-25