The term Turnkey Electronics Manufacturing is a buzzword in the modern electronics industry. But what is turnkey electronics manufacturing? This comprehensive approach to manufacturing is designed to streamline production, reduce costs, and enhance the efficiency of bringing a product from concept to market. In essence, it involves a manufacturer handling all stages of product development – from design to delivery. Learn more about turnkey vs consignment manufacturing.

Understanding the Basics of Turnkey Manufacturing

Turnkey manufacturing is a process where the manufacturer assumes full responsibility for the production process. This includes everything from procuring raw materials to quality assurance and final delivery. For businesses, especially exporters and importers looking to optimize their supply chain, this can be a game-changer.

The Role of a Turnkey Manufacturer

A turnkey manufacturer acts as a one-stop solution provider. They manage purchasing, production, and logistics, allowing businesses to focus on other critical areas such as marketing and sales. This integrated approach can lead to significant time and cost savings.

Advantages of Turnkey Electronics Manufacturing

There are several benefits to opting for a turnkey solution in electronics manufacturing. These include cost efficiency, streamlined processes, and reduced time to market. By eliminating the need for multiple suppliers, businesses can reduce overheads and streamline communication.

Cost Efficiency

One of the most significant advantages of turnkey electronics manufacturing is cost efficiency. By consolidating processes under one roof, manufacturers can reduce costs associated with logistics, inventory, and labor.

Streamlined Processes

With a single point of contact, businesses can enjoy a more streamlined production process. This reduces the complexity of managing multiple suppliers and helps ensure consistency in quality and delivery schedules.

Challenges in Turnkey Electronics Manufacturing

Despite its numerous benefits, turnkey manufacturing is not without challenges. These can include issues related to quality control, supply chain dependency, and the need for effective communication between the manufacturer and client.

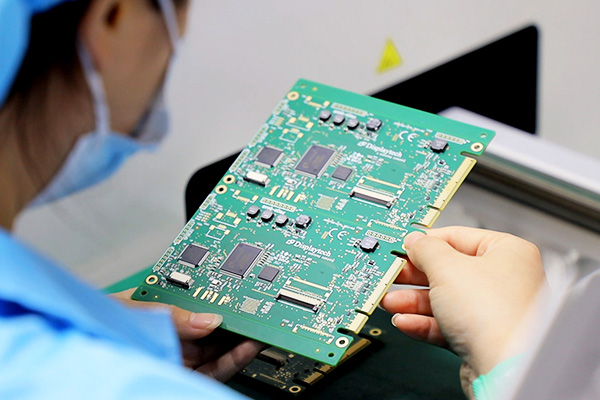

Quality Control

Maintaining high standards of quality is crucial. Companies must ensure that their turnkey provider has robust quality assurance processes in place to prevent defects and ensure customer satisfaction.

Supply Chain Dependency

Relying heavily on a single manufacturer can be risky. Businesses need to perform thorough due diligence to ensure their chosen provider is reliable and capable of meeting their needs consistently.

Steps to Choose the Right Turnkey Manufacturer

Choosing the right turnkey electronics manufacturer is crucial. Here are some steps to guide the decision-making process: identify your needs, research potential suppliers, and evaluate their capabilities and track record.

Identify Your Needs

Before selecting a manufacturer, it’s essential to have a clear understanding of your specific requirements. This includes product specifications, volume expectations, and any special certifications needed.

Research Potential Suppliers

Conduct thorough research on potential suppliers. Look for those with a proven track record in your industry and check their references and previous work.

Evaluate Capabilities

Assess the technical capabilities of the manufacturer. Ensure they have the necessary equipment, technology, and expertise to meet your product requirements.

The Future of Turnkey Electronics Manufacturing

As technology advances, the landscape of turnkey manufacturing is set to evolve. Innovations such as IoT, automation, and artificial intelligence are expected to play a significant role in shaping the future of the industry. Explore how 5G impacts IoT devices.

Integration of New Technologies

The integration of new technologies into manufacturing processes will enhance efficiency and reduce costs. Automation, in particular, is expected to play a significant role in transforming the industry.

Increased Demand for Customization

As consumer preferences become more diverse, there will be an increased demand for customized products. Turnkey manufacturers will need to adapt to this trend by offering more flexible solutions.

Sustainability and Environmental Impact

With growing awareness of environmental issues, there is a push towards more sustainable manufacturing practices. Turnkey manufacturers will need to adopt eco-friendly practices to meet market demands. Read about environmental monitoring in IoT.

Conclusion

In conclusion, turnkey electronics manufacturing offers numerous advantages for businesses looking to streamline their production processes. By understanding its benefits and challenges, companies can make informed decisions and choose the right partner to help them succeed in the competitive electronics industry.

FAQs

What is the primary advantage of turnkey manufacturing?

The primary advantage is cost efficiency and streamlined production processes, which help reduce time to market.

How can businesses ensure quality in turnkey manufacturing?

Businesses should choose manufacturers with robust quality assurance processes and a proven track record of delivering high-quality products.

What role does technology play in turnkey manufacturing?

Technology plays a crucial role in enhancing efficiency, reducing costs, and enabling customization within the turnkey manufacturing process.