As electronic devices become faster and more complex, the performance of printed circuit boards (PCBs) relies heavily on the precise management of electrical signals. One of the most critical aspects in high-speed PCB design is impedance control. This concept ensures that signals travel through the board with minimal distortion, preserving data integrity and reducing electromagnetic interference. Whether you are designing advanced communication equipment or consumer electronics, understanding the fundamentals of impedance control is essential for reliable circuit operation.

For those interested in foundational aspects of circuit design, you might also find value in exploring why PCB traces matter, which delves into how trace geometry affects overall board performance.

Understanding Controlled Impedance in PCB Design

In the context of circuit boards, controlled impedance refers to the precise regulation of the resistance that an electrical signal encounters as it travels along a trace. This resistance, or impedance, is not just about the opposition to direct current (DC) but also includes the effects of capacitance and inductance at high frequencies. When signals move at high speeds, mismatched impedance can lead to reflections, signal loss, and data errors.

The goal of impedance control is to match the impedance of the PCB traces to the requirements of the components and connectors in the circuit. This is especially important in high-frequency applications such as USB, HDMI, Ethernet, and RF circuits, where even small mismatches can cause significant problems.

Why Is Impedance Matching Important?

When designing a PCB, ensuring that the impedance of each trace matches the expected value is crucial for several reasons:

- Signal Integrity: Proper impedance management minimizes signal reflections and distortions, maintaining the quality of high-speed signals.

- Electromagnetic Compatibility: Mismatched impedance can increase electromagnetic emissions, potentially causing interference with other devices.

- Reliability: Consistent impedance across traces ensures that devices communicate reliably, reducing the risk of data loss or malfunction.

- Compliance: Many industry standards for communication protocols require strict impedance control to guarantee interoperability.

For a deeper understanding of how different board materials affect impedance, you may want to read about how to choose PCB substrate, which covers substrate selection and its impact on signal performance.

Key Factors Affecting Trace Impedance

Several variables influence the impedance of a PCB trace. Designers must consider these factors during layout and manufacturing to achieve the desired impedance:

- Trace Width: Wider traces have lower impedance, while narrower traces increase impedance.

- Trace Thickness: Thicker copper layers reduce impedance, but also affect current-carrying capacity.

- Dielectric Constant (Dk): The material between the trace and the reference plane affects the speed of signal propagation and the impedance value.

- Distance to Reference Plane: The closer the trace is to the ground or power plane, the lower the impedance.

- Trace Geometry: Microstrip (trace on outer layer) and stripline (trace between layers) configurations have different impedance characteristics.

Manufacturers use specialized software and calculations to determine the correct trace dimensions and stack-up to achieve the target impedance. This process often involves tight tolerances and close collaboration between designers and fabricators.

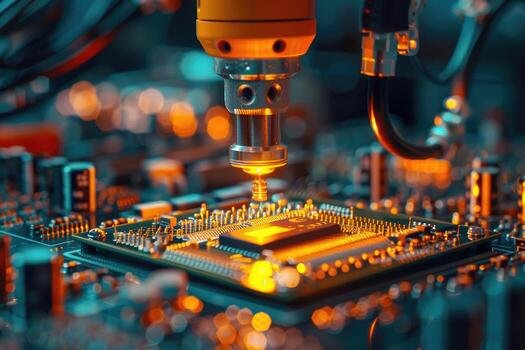

How Manufacturers Achieve Controlled Impedance

Achieving precise impedance requires a combination of design expertise and advanced manufacturing techniques. Here’s how the process typically unfolds:

- Design Calculation: Engineers use impedance calculators or simulation tools to determine the optimal trace width, spacing, and stack-up based on the board’s materials and intended signal speed.

- Stack-Up Planning: The arrangement of copper layers and dielectric materials is carefully planned to maintain consistent impedance throughout the signal path.

- Fabrication Controls: During production, manufacturers monitor copper thickness, etching processes, and dielectric properties to ensure specifications are met.

- Testing and Verification: After fabrication, specialized equipment measures the actual impedance of test coupons or traces to verify compliance with design targets.

For more on testing methods used in electronics manufacturing, see this overview of test methods for electronic components.

Common Applications Requiring Precise Impedance

Not all circuits demand strict impedance matching, but certain applications make it a necessity:

- High-Speed Digital Interfaces: Protocols like USB, HDMI, PCIe, and DDR memory require well-controlled impedance to function correctly.

- RF and Microwave Circuits: Wireless communication and radar systems rely on precise impedance for signal transmission and reception.

- Telecommunications: Ethernet, fiber optics, and other networking technologies depend on impedance control for data integrity over long distances.

- Medical and Industrial Equipment: Sensitive measurement and control systems often use impedance-controlled PCBs to minimize noise and errors.

Best Practices for Achieving Consistent Impedance

To ensure your board meets the required impedance specifications, consider these best practices:

- Collaborate Early: Work closely with your PCB manufacturer from the start to understand their capabilities and limitations.

- Specify Clearly: Provide detailed impedance requirements and stack-up diagrams in your fabrication notes.

- Use Standard Materials: Selecting commonly available dielectric materials can help maintain tighter tolerances.

- Request Test Coupons: Ask for impedance test coupons on your board panel for post-production verification.

- Review Tolerances: Understand the acceptable range for impedance variation and communicate this to your supplier.

For further reading on ensuring quality and reliability in electronics, you might also be interested in electronics troubleshooting basics.

Frequently Asked Questions

What happens if impedance is not controlled in a PCB?

If impedance is not properly managed, high-speed signals can experience reflections, loss, and distortion. This can lead to data errors, communication failures, and increased electromagnetic interference, especially in sensitive or high-frequency applications.

How do I know what impedance value my PCB traces should have?

The required impedance value depends on the communication protocol or component manufacturer’s specifications. Common values are 50 ohms for single-ended signals and 90 or 100 ohms for differential pairs. Always consult datasheets and industry standards for your specific application.

Can I achieve controlled impedance on a prototype or low-volume board?

Yes, but it requires careful planning and close communication with your PCB fabricator. Even for prototypes, specify your impedance requirements and request test coupons to verify the results. Using standard materials and stack-ups can help maintain consistency.

Are there tools to help with impedance calculation?

Many PCB design software packages include impedance calculators or simulators. Additionally, online tools and manufacturer-provided calculators can assist in determining the correct trace dimensions for your stack-up and materials.

For those working with protective coatings, consider reading about what is conformal coating to understand how coatings can further protect your PCB and its signal integrity.

Conclusion

Mastering impedance control is a vital skill for anyone involved in high-speed or high-frequency PCB design. By understanding the factors that influence impedance, collaborating with manufacturers, and following best practices, you can ensure your circuits perform reliably and meet industry standards. As technology continues to advance, the importance of precise impedance management will only grow, making it an essential topic for engineers and designers alike.