In the world of electronics manufacturing, protecting sensitive circuit boards and components from harsh environments is a top priority. One of the most effective methods for achieving this is through the application of conformal coating. This thin, protective film is designed to safeguard electronic assemblies from moisture, dust, chemicals, and temperature extremes, ensuring reliability and longevity in a wide range of applications.

Understanding how these protective layers work, the types available, and best practices for their application is essential for engineers, manufacturers, and anyone involved in electronics design or assembly. For those interested in broader protection strategies, exploring electronics packaging types can provide additional context on how devices are shielded from external threats.

Understanding Protective Coatings for Electronic Assemblies

At its core, a conformal coating is a thin polymeric film—usually between 25 to 250 micrometers thick—applied to printed circuit boards (PCBs) and other electronic components. The term “conformal” refers to the coating’s ability to closely follow the contours and irregularities of the underlying surface, providing a seamless barrier against environmental hazards.

The main objectives of these coatings are to:

- Prevent corrosion caused by moisture and contaminants

- Protect against dust, chemicals, and salt spray

- Reduce the risk of electrical shorts and leakage currents

- Enhance mechanical stability and vibration resistance

These benefits are especially critical in industries such as automotive, aerospace, medical devices, and consumer electronics, where reliability is non-negotiable.

Types of Conformal Coating Materials

Several types of materials are used for protective coatings, each offering unique properties and suited to different environments. The most common varieties include:

- Acrylics (AR): Known for their ease of application and removal, acrylic coatings offer good moisture and humidity protection. They are often chosen for general-purpose use.

- Silicones (SR): These provide excellent thermal stability and flexibility, making them ideal for high-temperature and high-humidity environments.

- Polyurethanes (UR): Offering strong chemical and abrasion resistance, polyurethanes are suitable for harsh industrial settings.

- Epoxies (ER): With their tough, durable finish, epoxies are used where mechanical strength is essential, though they can be more challenging to remove for rework.

- Parylene: Applied via vapor deposition, parylene coatings provide a pinhole-free, ultra-thin barrier with excellent dielectric properties, often used in medical and aerospace applications.

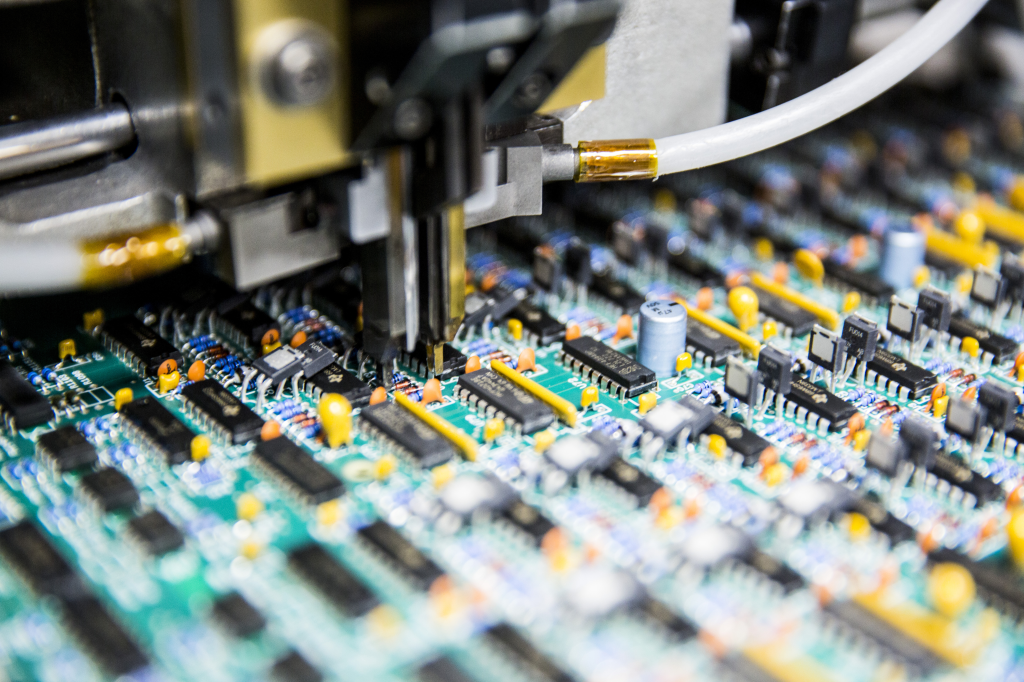

How Protective Coatings Are Applied in Electronics

The process of applying a conformal coating involves several key steps to ensure optimal coverage and performance:

- Surface Preparation: The PCB must be thoroughly cleaned to remove dust, oils, and residues. Any contamination can compromise adhesion and effectiveness.

- Masking: Areas that should not be coated—such as connectors, switches, or test points—are masked off using tapes or custom boots.

-

Application: Coatings can be applied using various methods, including:

- Brushing (for small batches or touch-ups)

- Spraying (manual or automated for larger production runs)

- Dipping (submerging the assembly for complete coverage)

- Selective coating machines (for precise, automated application)

- Curing: Depending on the material, curing may involve air drying, heat, or UV light to harden the coating.

- Inspection and Testing: Visual inspection, UV light checks (for fluorescent coatings), and electrical testing ensure proper coverage and functionality.

For a more comprehensive look at manufacturing processes, the ultimate guide to electronics manufacturing covers the broader workflow and quality control measures.

Key Benefits of Using Protective Films on PCBs

Applying a conformal coating to electronic assemblies offers several advantages:

- Enhanced Reliability: By shielding circuits from moisture and contaminants, the risk of corrosion and failure is greatly reduced.

- Extended Service Life: Devices last longer, even in demanding environments such as marine, automotive, or industrial settings.

- Improved Electrical Performance: The coating minimizes leakage currents and prevents short circuits caused by conductive debris.

- Reduced Maintenance: With better protection, assemblies require less frequent repairs or replacements.

- Cost Efficiency: While there is an upfront cost, the reduction in field failures and warranty claims often results in long-term savings.

Challenges and Best Practices in Applying Conformal Coating

While the benefits are clear, there are also challenges associated with the use of protective films in electronics:

- Application Consistency: Achieving uniform thickness and coverage, especially on densely populated boards, can be difficult without proper equipment and training.

- Rework and Repair: Some coatings are difficult to remove, complicating repairs or modifications to the assembly.

- Material Compatibility: Not all coatings are suitable for every component or assembly. Chemical compatibility and thermal expansion must be considered.

- Inspection: Detecting voids, bubbles, or missed areas requires careful inspection, often using UV light or automated optical systems.

To maximize the effectiveness of these protective layers, follow these best practices:

- Always clean and dry assemblies thoroughly before application.

- Use proper masking to protect sensitive areas.

- Select the coating material based on environmental requirements and rework needs.

- Employ automated application methods for high-volume production to ensure consistency.

- Regularly inspect coated assemblies for defects or incomplete coverage.

For additional insights into assembly processes, reviewing electronic assembly best practices can help ensure quality at every stage.

Frequently Asked Questions About Conformal Coating

What are the most common applications for protective coatings in electronics?

These coatings are widely used in automotive electronics, aerospace systems, consumer devices, medical equipment, and industrial controls. Any environment where moisture, dust, or chemicals could threaten circuit integrity can benefit from this protection.

Can conformal coatings be removed for repairs or modifications?

Yes, but the ease of removal depends on the type of material used. Acrylics are generally easier to remove with solvents, while silicones and epoxies may require mechanical abrasion or specialized chemicals. Always consult the coating manufacturer’s guidelines before attempting removal.

How do you inspect coated assemblies for proper coverage?

Inspection typically involves visual checks under normal and UV light (for fluorescent coatings). Automated optical inspection systems can also be used in high-volume production to detect voids, bubbles, or missed areas.

Is conformal coating always necessary for PCBs?

Not all assemblies require this level of protection. The decision depends on the intended environment and reliability requirements. For devices exposed to harsh or variable conditions, applying a protective film is highly recommended.

Conclusion

Conformal coatings play a vital role in modern electronics, providing a reliable barrier against environmental threats and extending the service life of sensitive assemblies. By understanding the types of materials available, proper application methods, and best practices, manufacturers and engineers can ensure their products perform reliably in even the most challenging conditions. For a deeper dive into manufacturing workflows, consider reading about the electronics fabrication workflow and how quality control is maintained throughout the process.