In the world of printed circuit board (PCB) manufacturing, the term Gerber file comes up frequently. These files are a fundamental part of how electronic circuits are brought from digital design to physical reality. Whether you’re a hobbyist, an engineer, or simply curious about electronics production, understanding the role of Gerber files is essential for anyone involved in PCB projects.

This guide will break down the purpose, structure, and importance of Gerber files in circuit board fabrication. You’ll learn how they fit into the broader PCB workflow, the different types of data they contain, and best practices for preparing them for manufacturing. For those interested in the steps that follow Gerber file creation, you may also want to review the PCB etching process explained to see how these files are used in practice.

Understanding the Role of Gerber Files in Electronics Manufacturing

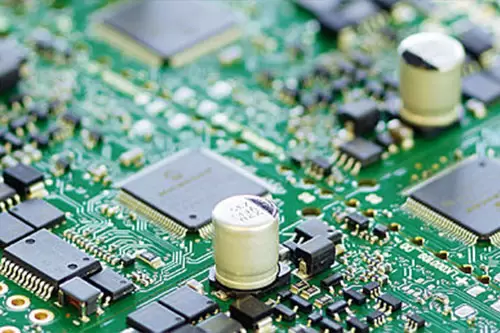

At its core, a Gerber file is a standardized format used to describe the images and layers of a PCB. These files instruct fabrication equipment on exactly how to create each layer of the board, including copper traces, solder masks, silkscreens, and more. Without this precise set of instructions, manufacturers would not be able to produce complex circuit boards reliably or consistently.

The Gerber format has become the industry standard because it ensures compatibility between different design software and manufacturing hardware. This universal approach allows designers and fabricators around the world to collaborate with confidence, knowing that their files will be interpreted correctly regardless of the tools used.

Key Components Contained in Gerber Files

When you export a PCB design for manufacturing, you typically generate a collection of Gerber files—each one representing a different aspect of the board. Here are the most common types of data included:

- Copper Layers: Define the conductive paths (traces) and pads on each layer of the PCB.

- Solder Mask Layers: Indicate areas to be covered with solder-resistant material, protecting the copper and preventing solder bridges.

- Silkscreen Layers: Contain text, logos, and component outlines printed on the board’s surface for identification and assembly.

- Drill Files: Specify the locations and sizes of holes for vias, component leads, and mounting points.

- Paste Mask Layers: Used for surface-mount technology (SMT), these define where solder paste should be applied.

- Board Outline: Provides the exact shape and size of the finished PCB.

Each of these files is critical for ensuring the final product matches the designer’s intent. Missing or incorrect files can lead to manufacturing delays or defective boards.

How Gerber Files Are Generated and Used

Most PCB design software, such as Altium Designer, Eagle, or KiCAD, can export Gerber files directly from your project. The process typically involves selecting which layers to include, setting up file naming conventions, and verifying the output with a Gerber viewer.

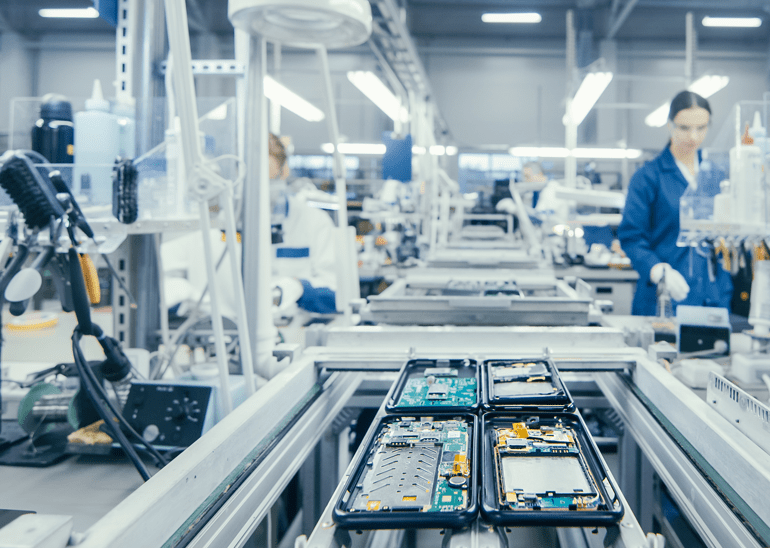

Once created, these files are sent to the PCB manufacturer, who loads them into their fabrication equipment. The machines use the data to image, etch, drill, and assemble the board according to the precise instructions provided. This digital-to-physical workflow is what makes modern electronics manufacturing efficient and scalable.

Common Gerber File Formats and Standards

Over the years, several versions of the Gerber format have been developed. The most widely used today is the RS-274X (Extended Gerber) format, which supports embedded aperture definitions and is much more robust than earlier versions like RS-274D. The RS-274X format is considered the de facto standard for modern PCB manufacturing.

In addition to Gerber files, manufacturers may request accompanying files such as Excellon drill files and assembly drawings. It’s important to check with your fabricator to ensure you’re providing all required data in the correct format.

Why Accurate Gerber Files Matter for PCB Quality

The accuracy of your Gerber files directly impacts the quality and reliability of the finished circuit board. Even small errors—such as misaligned layers, missing apertures, or incorrect drill data—can result in costly manufacturing defects.

To avoid these issues, always review your files with a dedicated Gerber viewer before submitting them. Many design tools offer built-in verification features, but third-party viewers can provide an extra layer of confidence. Taking the time to double-check your files helps prevent delays and ensures your PCB meets both functional and quality requirements.

Best Practices for Preparing and Submitting Gerber Files

Here are some practical tips for working with Gerber files:

- Use clear, consistent file naming conventions so manufacturers can easily identify each layer.

- Include all required layers—copper, solder mask, silkscreen, drill, and outline.

- Verify the files using a Gerber viewer to catch errors before submission.

- Communicate with your manufacturer to confirm their preferred formats and any special requirements.

- Provide a readme or fabrication notes if your design has unique features or assembly instructions.

Following these steps helps ensure a smooth transition from design to production, reducing the risk of costly mistakes.

Related Concepts and Further Reading

Understanding Gerber files is just one part of the broader PCB design and manufacturing process. For a deeper dive into how circuit boards are constructed, you might explore topics like understanding PCB layers or the how SMT assembly works. For those interested in the differences between assembly techniques, the article on the difference between SMT and through hole assembly offers valuable insights.

Additionally, learning about soldering techniques explained can help you understand the final steps in electronics assembly. For a broader perspective on quality assurance, this overview of test methods for electronic components provides useful information on ensuring your finished boards meet industry standards.

Frequently Asked Questions

What information does a Gerber file contain?

A Gerber file contains graphical data for each layer of a PCB, including copper traces, solder mask, silkscreen, and board outline. It tells the manufacturer exactly how to image and fabricate each part of the circuit board.

Are Gerber files required for all PCB manufacturing?

Yes, Gerber files are the industry standard for communicating PCB design data to manufacturers. Without them, fabricators cannot accurately produce the board as designed.

How can I check if my Gerber files are correct?

You can use a Gerber viewer—either standalone or built into your PCB design software—to visually inspect each layer and ensure all features are present and correctly aligned before sending files to your manufacturer.