In the world of electronics manufacturing, one of the critical decisions businesses face is choosing between turnkey vs in-house electronics production. Both approaches offer distinct advantages and challenges, making it crucial for companies to carefully evaluate their options. This article will explore the intricacies of both methods, helping exporters and importers determine which path best aligns with their operational needs and business goals.

Understanding Turnkey Production

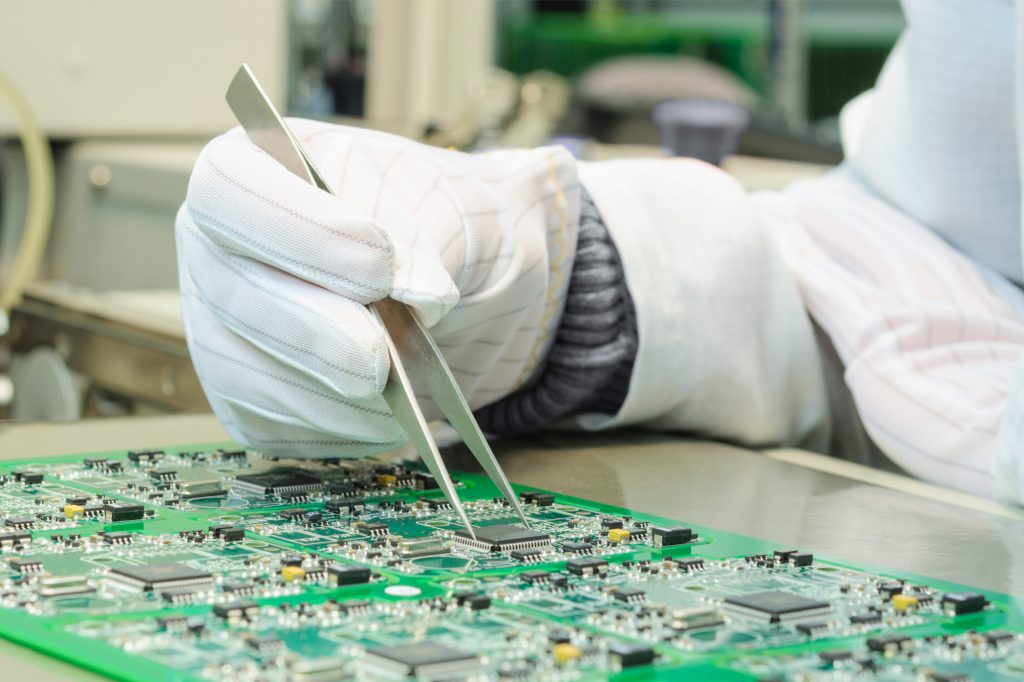

Turnkey production refers to a comprehensive approach where a single provider manages the entire production process from start to finish. This method allows businesses to outsource the complexities of production, including design, manufacturing, and logistics, to a specialized third-party vendor. Many organizations opt for turnkey solutions to leverage the expertise and resources of experienced manufacturers.

Key Advantages of Turnkey Production

One of the primary benefits of turnkey production is its ability to streamline operations. By consolidating the entire manufacturing process under one roof, businesses can enjoy enhanced efficiency and reduced overhead costs. Additionally, turnkey providers often have established relationships with suppliers, enabling them to secure materials at competitive prices. This cost-effectiveness is particularly appealing to companies looking to optimize their budgets.

For more insights on how turnkey manufacturing can reduce overhead, you can visit this link.

Challenges in Turnkey Production

While turnkey solutions offer numerous benefits, they also present certain challenges. One potential drawback is the lack of direct control over the production process. Companies relying on turnkey services must place significant trust in their chosen vendors, making it essential to conduct thorough research and select reputable partners.

Exploring In-House Production

In contrast to turnkey methods, in-house production involves managing the entire manufacturing process within the organization’s facilities. This approach provides companies with complete control over every aspect of production, from design and prototyping to assembly and quality control.

Benefits of In-House Production

One of the standout advantages of in-house production is the level of control it offers. Companies can directly oversee every step of the process, ensuring that products meet their exact specifications and quality standards. This control allows for greater flexibility and the ability to make real-time adjustments based on market demands.

Drawbacks of In-House Production

Despite its benefits, in-house production can be resource-intensive. Establishing and maintaining a production facility requires significant investment in infrastructure, equipment, and skilled labor. Additionally, companies must navigate supply chain complexities and manage inventory, which can strain resources and impact profitability.

Comparing Costs: Turnkey vs In-House

When evaluating turnkey vs in-house electronics production, cost considerations play a pivotal role. Turnkey solutions often provide cost savings due to economies of scale and streamlined processes. On the other hand, in-house production may involve higher upfront costs, but it can offer long-term savings through optimized production and reduced reliance on external vendors.

Quality Assurance in Production

Ensuring consistent product quality is a top priority for electronics manufacturers. Turnkey providers typically have established quality assurance processes in place, minimizing the risk of defects. For an in-depth look at how turnkey solutions ensure consistent quality, you can explore this resource.

In-house production allows for rigorous quality control, as companies can implement their own testing and inspection protocols. This autonomy enables businesses to maintain their standards and uphold their brand reputation.

Time to Market Considerations

Speed to market is a crucial factor in the competitive electronics industry. Turnkey solutions often offer faster time to market due to their streamlined processes and established supplier networks. In contrast, in-house production may require longer lead times for setting up facilities and sourcing materials.

Scalability and Flexibility

Scalability is another critical consideration when choosing between turnkey vs in-house electronics production. Turnkey providers can quickly adapt to changes in demand, allowing businesses to scale their operations efficiently. This flexibility is particularly advantageous for companies experiencing rapid growth.

The Role of Technology

Technological advancements play a significant role in modern electronics manufacturing. Turnkey providers often leverage cutting-edge technologies to enhance production efficiency and quality. In-house production can also benefit from technology, but it requires investments in equipment and training.

Environmental Impact

Sustainability is a growing concern for businesses worldwide. Turnkey providers may have established sustainability practices, reducing the environmental impact of production. In-house production allows companies to implement eco-friendly initiatives aligned with their corporate values.

Case Studies: Turnkey Success Stories

Many companies have achieved remarkable success with turnkey solutions. For instance, automotive electronics manufacturers have leveraged turnkey production to streamline operations and enhance product quality. For more information on turnkey manufacturing for automotive electronics, you can visit this link.

Case Studies: In-House Production Success

In-house production has also proven successful for companies prioritizing control and customization. By managing every aspect of production, businesses can create unique products that stand out in the market.

Conclusion: Making the Right Choice

Ultimately, the decision between turnkey vs in-house electronics production depends on a company’s specific needs, resources, and goals. Turnkey solutions offer convenience and efficiency, while in-house production provides control and customization. By carefully evaluating their priorities, businesses can choose the approach that best aligns with their strategic objectives.

FAQs

What is turnkey production in electronics?

Turnkey production in electronics refers to a comprehensive approach where a single provider manages the entire manufacturing process, from design to delivery.

What are the benefits of in-house production?

In-house production offers complete control over the manufacturing process, allowing companies to ensure quality, customization, and flexibility.

How does turnkey production improve efficiency?

Turnkey production improves efficiency by streamlining operations, leveraging established supplier networks, and reducing overhead costs.

For additional insights on automated inspection in turnkey electronics, you can explore this resource.

For more external insights on turnkey PCB assembly, you can visit EMSG.