In the dynamic landscape of global manufacturing and logistics, the choice between turnkey procurement vs customer supplied parts is a pivotal decision for exporters and importers. This decision can significantly impact the efficiency and cost-effectiveness of a supply chain. Understanding the nuances of both approaches is crucial for making informed choices that align with business goals.

Understanding Turnkey Procurement

Turnkey procurement refers to a comprehensive approach where the supplier manages the entire procurement process. This includes sourcing, purchasing, and delivering all parts necessary for production. The supplier takes full responsibility for ensuring that the right components are available at the right time.

Advantages of Turnkey Procurement

The primary advantage of turnkey procurement is its convenience. By relying on a single supplier to handle all procurement tasks, companies can focus on their core competencies. This approach often leads to better supply chain efficiency and reduced administrative burdens. Furthermore, suppliers often have established relationships with manufacturers, which can result in cost savings and improved quality control.

For a deeper dive into the benefits of turnkey solutions, you can explore how turnkey ensures consistent product quality.

Challenges of Turnkey Procurement

Despite its advantages, turnkey procurement may not be suitable for every business. Relying heavily on a single supplier can lead to dependency risks. Additionally, companies may have less control over the specific parts being used, which can be a concern for specialized industries with stringent quality requirements.

Exploring Customer Supplied Parts

Conversely, customer supplied parts involve the company providing specific parts to the manufacturer. This approach allows businesses to maintain control over component quality and specifications. It is often preferred by companies operating in industries with rigorous standards, such as aerospace or medical devices.

Advantages of Customer Supplied Parts

One of the main benefits of customer supplied parts is quality assurance. Companies can ensure that the parts meet their standards, reducing the risk of defects or failures. Additionally, this approach allows for greater customization and flexibility in the manufacturing process.

For insights on how this approach can benefit specific industries, consider exploring turnkey manufacturing for automotive electronics.

Challenges of Customer Supplied Parts

However, managing customer supplied parts can be complex and resource-intensive. Companies need robust systems to track and manage inventory, which can lead to increased overhead costs. Additionally, the logistical challenges of supplying parts to the manufacturer can complicate the production timeline.

Comparative Analysis: Turnkey Procurement vs Customer Supplied Parts

When weighing turnkey procurement vs customer supplied parts, businesses must consider several factors. These include cost implications, quality control, supply chain complexity, and the ability to meet production timelines. Each approach has its own set of strengths and challenges, making it essential to align the choice with strategic business goals.

Strategic Considerations for Exporters and Importers

For exporters and importers, the decision between turnkey procurement and customer supplied parts can also influence international logistics. Turnkey solutions may simplify the import/export process, as the supplier handles the sourcing and delivery of components. On the other hand, using customer supplied parts requires careful coordination to ensure compliance with international trade regulations.

Impact on Supply Chain Management

Effective supply chain management is crucial for both approaches. Companies must weigh the benefits of streamlined operations against the need for control over part specifications. Understanding the impact of each approach on the supply chain can help businesses optimize their operations.

For more information on this, read about how turnkey helps reduce overhead.

The Role of Technology in Decision-Making

Technological advancements have made it easier for companies to manage procurement processes. Tools like ERP systems can help businesses track inventory, manage supplier relationships, and streamline operations. This technology is particularly beneficial for managing complex supply chains with either turnkey procurement or customer supplied parts.

Future Trends in Procurement

The future of procurement is likely to see an increased integration of digital solutions. Automation and data analytics will play a crucial role in optimizing procurement processes, enhancing efficiency, and reducing costs.

For a look at how automation can impact your processes, explore automated inspection in turnkey electronics.

Conclusion: Making the Right Choice

In conclusion, the choice between turnkey procurement vs customer supplied parts is not one-size-fits-all. Businesses must carefully evaluate their unique needs, industry requirements, and strategic objectives. Both approaches offer distinct advantages and challenges that must be considered in the context of the companys goals.

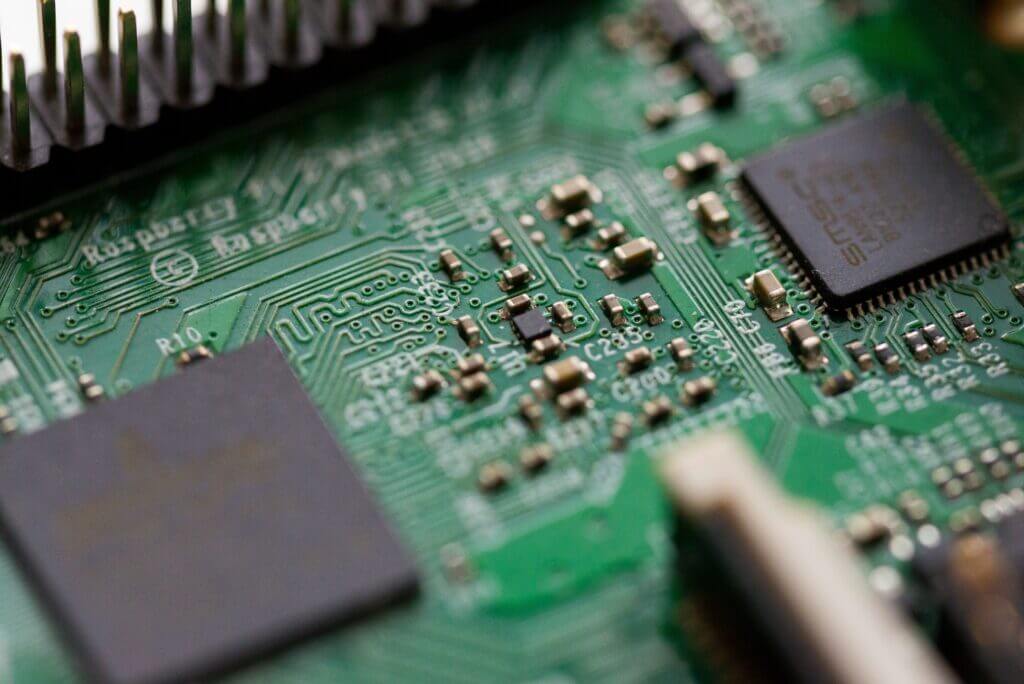

For those seeking a comprehensive understanding of these procurement strategies, consider visiting What is Turnkey PCB Assembly? for further insights.

FAQ Section

What is the main advantage of turnkey procurement?

The main advantage of turnkey procurement is convenience and efficiency, as it allows a single supplier to manage the entire procurement process.

Why might a company choose customer supplied parts?

A company might choose customer supplied parts to maintain control over the quality and specifications of components, particularly in industries with rigorous standards.

How does technology impact these procurement choices?

Technology, such as ERP systems, can significantly enhance the management of procurement processes by improving tracking, efficiency, and supplier relationships.