In today’s fast-paced electronics industry, the integration of turnkey PCB assembly with quality control has become a cornerstone for many exporters and importers. This approach not only ensures product reliability but also optimizes the overall manufacturing process. Whether you’re an experienced player in the market or new to the industry, understanding the nuances of turnkey PCB assembly can significantly benefit your business operations.

What Is Turnkey PCB Assembly?

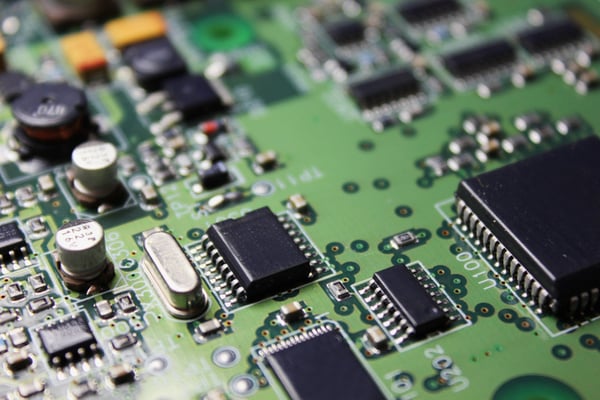

Turnkey PCB assembly refers to a comprehensive service where a single provider handles all aspects of the printed circuit board production process. From the initial design and procurement of components to the final assembly and testing, a turnkey service delivers a complete product ready for use. This streamlined approach is particularly advantageous for exporters and importers who require efficient and reliable electronics manufacturing solutions.

The Importance of Quality Control

Quality control is integral to the success of turnkey PCB assembly. It encompasses rigorous testing and inspection processes to ensure that every board meets the specified standards and functions as intended. For exporters and importers, maintaining high-quality standards is crucial to building trust with clients and avoiding costly product recalls or failures.

Benefits of Quality Control in PCB Assembly

- Improved product reliability and performance.

- Minimized risk of defects and failures.

- Enhanced customer satisfaction and brand reputation.

How Turnkey PCB Assembly Enhances Efficiency

By consolidating the entire production process under one roof, turnkey PCB assembly significantly enhances efficiency. This approach reduces lead times and simplifies logistics, allowing businesses to focus on other critical aspects of their operations. For an in-depth understanding of how this process can improve quality, you can refer to this article.

Streamlined Supply Chain Management

With turnkey PCB assembly, the supply chain is more streamlined, reducing the complexity often associated with managing multiple vendors. This not only cuts down on potential errors but also saves time and resources. For more insights on supply chain management, visit this resource.

Challenges and Solutions in Turnkey PCB Assembly

Despite its advantages, turnkey PCB assembly does come with its challenges. These may include managing complex designs, ensuring component availability, and maintaining communication between different teams. However, with proper planning and execution, these challenges can be effectively addressed.

Overcoming Design Complexity

One of the primary challenges in turnkey PCB assembly is handling complex circuit designs. To overcome this, manufacturers often employ advanced design software and experienced engineers to ensure that all specifications are met accurately.

Why Exporters and Importers Should Consider Turnkey Solutions

For exporters and importers, the decision to opt for turnkey PCB assembly can be a game-changer. It simplifies the manufacturing process and provides a competitive edge in the global market. By partnering with a reliable turnkey provider, businesses can ensure that their products meet international standards and are delivered on time.

Cost-Effectiveness

While the initial costs of turnkey PCB assembly might seem higher, the long-term savings from reduced errors, faster production times, and better quality control make it a cost-effective choice. For more information on the benefits of turnkey solutions, explore this blog.

Choosing the Right Turnkey PCB Assembly Provider

Selecting a reliable provider for turnkey PCB assembly is crucial. Businesses should look for providers with a proven track record, robust quality control measures, and the ability to handle complex projects. An informative resource on what to look for in a provider can be found here.

Key Considerations

- Experience and expertise in the industry.

- Quality control protocols.

- Customer reviews and testimonials.

FAQs

What is the main advantage of turnkey PCB assembly?

The main advantage is the integration of all manufacturing processes, which results in faster production times and improved product quality.

How does quality control impact PCB assembly?

Quality control ensures that each PCB meets the required standards and functions correctly, reducing the risk of defects and enhancing reliability.

What should I look for in a turnkey provider?

Look for a provider with extensive experience, strong quality control measures, and positive customer feedback.