In today’s fast-paced technology landscape, the demand for efficient and reliable printed circuit boards (PCBs) continues to grow. One of the most effective solutions to meet this demand is turnkey PCB assembly for SMT boards. This approach not only streamlines the production process but also ensures high-quality results, making it a popular choice among manufacturers.

Whether you’re an exporter or importer, understanding the intricacies of turnkey PCB assembly can offer significant advantages. This article aims to provide a deep dive into the world of turnkey PCB assembly for SMT boards, exploring its benefits, processes, and applications.

What is Turnkey PCB Assembly?

Turnkey PCB assembly refers to a comprehensive service where the provider manages all aspects of the PCB production process. This includes design, component sourcing, assembly, testing, and delivery. The term ‘turnkey’ implies that the customer only needs to ‘turn the key’ to start using the product.

Understanding SMT Boards

Surface Mount Technology (SMT) is widely used in the electronics industry for assembling PCBs. SMT involves placing components directly onto the surface of the board, allowing for more compact and efficient designs.

Benefits of SMT

SMT offers several advantages over traditional through-hole technology, including smaller size, higher component density, and improved performance. It also allows for automated assembly, reducing labor costs and improving consistency.

The Turnkey PCB Assembly Process

Design and Prototyping

The process begins with the design and prototyping phase, where the initial concept is developed into a functional prototype. This stage is crucial for identifying potential issues and making necessary adjustments before mass production.

Component Sourcing

Once the design is finalized, the next step is component sourcing. Turnkey providers have established relationships with suppliers, ensuring access to high-quality components at competitive prices.

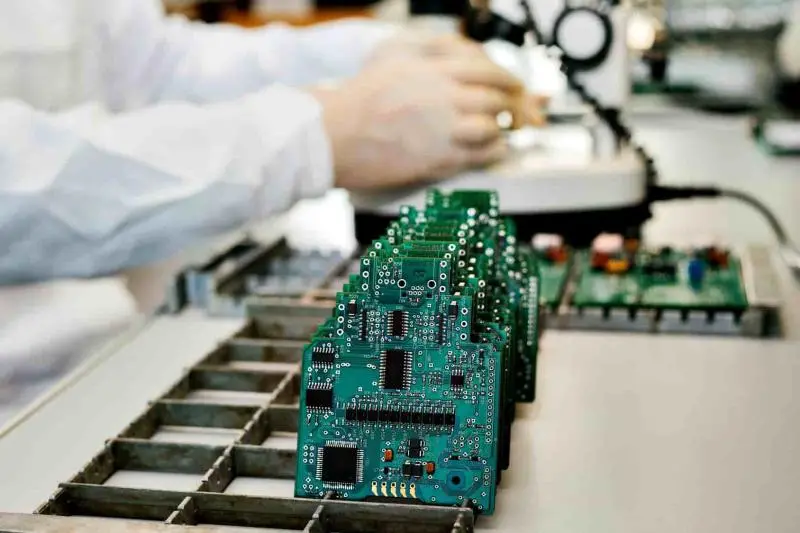

Assembly and Testing

The assembly process involves placing and soldering components onto the PCB. This is followed by rigorous testing to ensure functionality and reliability. Automated inspection techniques are often used to identify defects and ensure quality.

Advantages of Turnkey PCB Assembly for SMT Boards

Streamlined Process

By outsourcing the entire PCB production process to a single provider, customers can benefit from a streamlined workflow. This reduces the time and effort required to manage multiple vendors.

Cost-Effectiveness

Turnkey assembly can be more cost-effective than managing each stage independently. Providers can leverage their purchasing power to secure better prices on components, and the reduced labor costs associated with automated assembly contribute to overall savings.

Quality Assurance

Turnkey providers implement strict quality control measures throughout the assembly process. This ensures that the final product meets the required standards and functions as intended.

Applications of Turnkey PCB Assembly

Turnkey PCB assembly is used across various industries, including consumer electronics, automotive, aerospace, and telecommunications. Its versatility and efficiency make it an ideal solution for both small and large-scale production.

Choosing a Turnkey PCB Assembly Provider

When selecting a turnkey provider, it’s important to consider factors such as experience, reputation, and the range of services offered. A reliable provider should have a proven track record and be able to deliver high-quality products on time.

The Future of Turnkey PCB Assembly

As technology continues to evolve, the demand for more advanced and efficient PCBs is expected to increase. Turnkey assembly will play a crucial role in meeting this demand, offering a reliable and cost-effective solution for manufacturers worldwide.

Conclusion

In conclusion, turnkey PCB assembly for SMT boards offers numerous benefits, from streamlined processes to cost savings and quality assurance. By understanding the intricacies of this approach, exporters and importers can make informed decisions and stay competitive in the ever-changing electronics market.

FAQs

What is the difference between turnkey and traditional PCB assembly?

Turnkey PCB assembly involves outsourcing the entire production process to a single provider, while traditional assembly requires managing each stage independently. Turnkey assembly offers a more streamlined and cost-effective solution.

How long does the turnkey PCB assembly process take?

The duration of the turnkey PCB assembly process can vary depending on the complexity of the design and the production volume. However, it generally offers faster turnaround times compared to traditional methods.

What industries benefit from turnkey PCB assembly?

Turnkey PCB assembly is used in a variety of industries, including consumer electronics, automotive, aerospace, and telecommunications. Its efficiency and versatility make it suitable for both small and large-scale production.

For more information on turnkey PCB assembly, visit Hetech.

Additionally, you can explore how turnkey procurement compares to customer-supplied parts, or delve into the role of turnkey engineers in supporting PCB design.