In the world of electronics manufacturing, turnkey PCB assembly for BGA packages is a concept that is gaining significant importance. This is particularly true for exporters and importers who are constantly seeking reliable and efficient methods to produce high-quality PCBs. Before delving deeper, it’s crucial to understand what turnkey PCB assembly entails, especially when dealing with BGA packages.

What is Turnkey PCB Assembly?

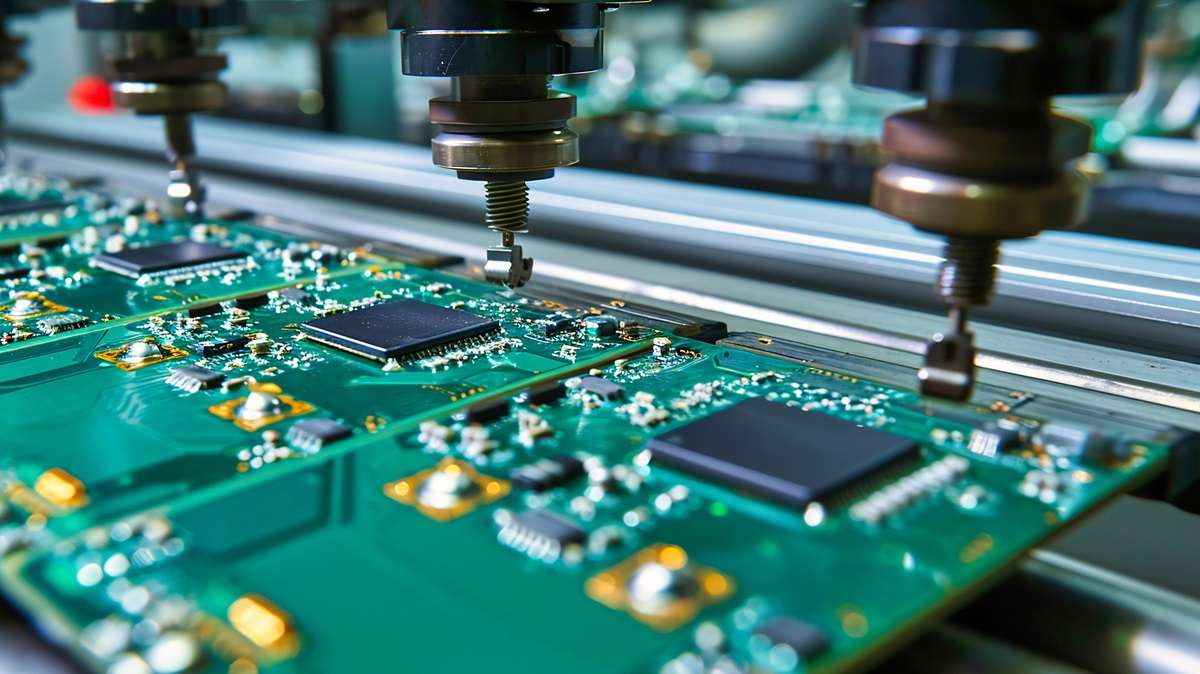

Turnkey PCB assembly is a process where the manufacturing company handles all aspects of PCB production. This includes sourcing components, producing the PCB, assembling the components, and finally, testing the finished product. This approach saves time and reduces complexities for businesses as it alleviates the need to deal with multiple suppliers and manufacturers.

Understanding BGA Packages

BGA, or Ball Grid Array, is a type of surface-mount packaging used for integrated circuits. It’s favored for its ability to provide more interconnection pins than can be put on a dual in-line or flat package. This makes BGAs an excellent choice for complex and high-performance electronics.

Why Choose Turnkey PCB Assembly for BGA Packages?

There are several reasons why businesses might opt for turnkey PCB assembly when dealing with BGA packages:

- Efficiency: Turnkey services streamline the production process, reducing lead times and potential errors.

- Cost-Effectiveness: By consolidating the supply chain and manufacturing processes, companies can often reduce costs.

- Quality Assurance: With a single point of contact, ensuring quality becomes simpler and more effective.

The Process of Turnkey PCB Assembly for BGA Packages

The process typically involves several key stages:

1. Design and Prototyping

This stage involves creating a detailed design of the PCB and a prototype to ensure all requirements are met. For more details, you can read about the differences between electronics prototyping vs mass production.

2. Component Sourcing

All necessary components are sourced, often through established relationships with suppliers to ensure quality and compatibility.

3. PCB Fabrication

The actual production of the PCB takes place, followed by rigorous testing to ensure it meets the specified requirements.

4. Assembly and Testing

The components are then assembled onto the PCB, and the final product is tested to confirm functionality and quality.

Challenges in Turnkey PCB Assembly for BGA Packages

Despite its benefits, there are challenges associated with turnkey PCB assembly for BGA packages:

- Complexity: BGAs are inherently complex, requiring precise handling and assembly techniques.

- Thermal Management: Proper thermal management is crucial to prevent overheating and ensure longevity.

Choosing a Reliable Turnkey PCB Assembly Partner

When selecting a partner for turnkey PCB assembly, consider factors such as experience, technology, and customer service. A good partner can be the difference between success and failure in electronics manufacturing.

For a deeper understanding of the benefits, you can explore turnkey procurement vs customer-supplied parts.

Case Study: Successful Turnkey PCB Assembly for BGA Packages

Consider a company that successfully implemented turnkey PCB assembly for a new line of high-performance BGAs. By working with an experienced partner, they reduced costs by 20% and improved time-to-market by 15%.

Industry Trends in Turnkey PCB Assembly

The industry is seeing a shift towards more integrated and automated processes. As technology advances, the demand for efficient and reliable PCB assembly will continue to grow. Learn more about these trends in DFX in turnkey manufacturing processes.

Future of Turnkey PCB Assembly for BGA Packages

Looking ahead, the future of turnkey PCB assembly for BGA packages seems promising. With continuous advancements in technology, we can expect even more efficient and cost-effective solutions.

Conclusion

In conclusion, turnkey PCB assembly for BGA packages offers a comprehensive solution for businesses looking to streamline their production processes. By choosing the right partner and understanding the intricacies involved, companies can achieve significant benefits in terms of cost, efficiency, and quality.

For a complete guide to turnkey electronics manufacturing, visit Hitek Quality.

FAQ

What are the benefits of turnkey PCB assembly?

Turnkey PCB assembly offers numerous benefits, including streamlined processes, cost savings, and improved quality control.

How does BGA packaging improve PCB design?

BGA packaging allows for more interconnection pins, improving the overall functionality and performance of the PCB.

What should I look for in a turnkey PCB assembly partner?

When choosing a partner, consider their experience, technology, and customer service. A reliable partner will ensure a smooth and successful production process.