In today’s fast-paced industrial landscape, businesses are constantly seeking efficient ways to introduce new products to the market. One popular approach is through turnkey manufacturing for pilot runs. This method has transformed the way companies bring their innovations to life, providing a streamlined process that saves both time and resources.

What is Turnkey Manufacturing?

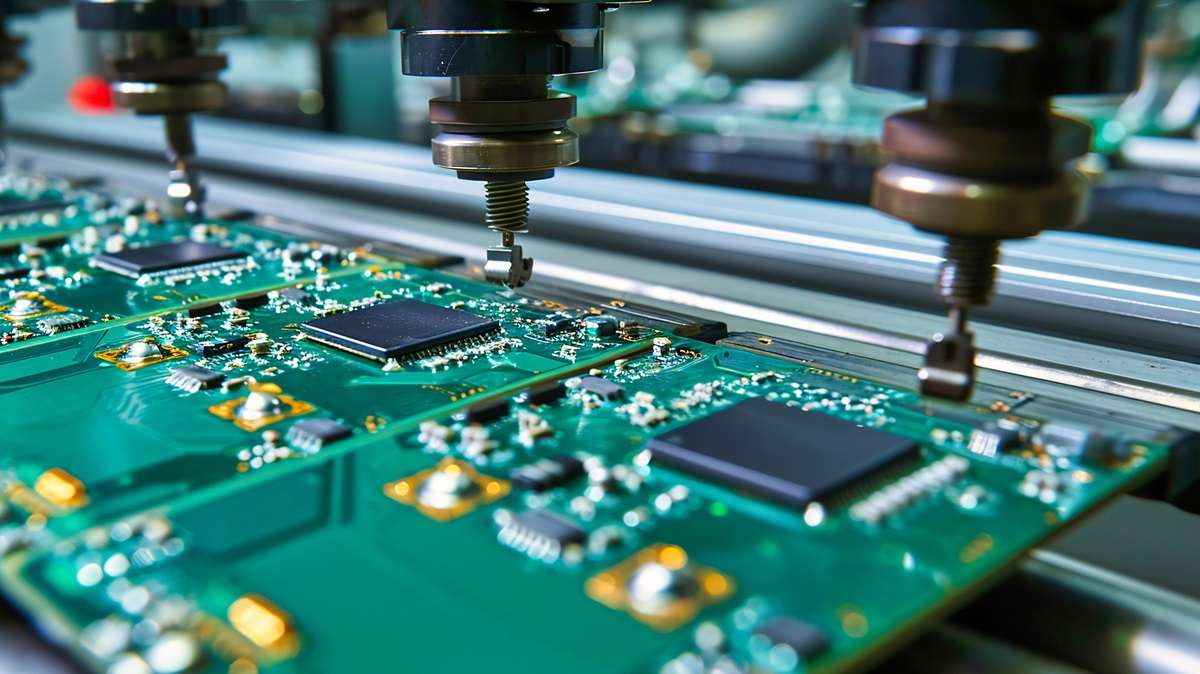

Turnkey manufacturing is a comprehensive service where a single provider manages the entire production process from start to finish. This includes everything from design and prototyping to production and quality control. For pilot runs, this approach is particularly beneficial as it allows companies to test and refine their products before full-scale production.

Why Choose Turnkey Manufacturing for Pilot Runs?

Choosing turnkey manufacturing for your pilot runs offers numerous advantages. Not only does it simplify the production process, but it also ensures consistency and quality. By entrusting the entire process to a single provider, businesses can focus on other critical areas such as marketing and sales.

Streamlined Process

One of the main benefits of turnkey manufacturing is the streamlined process it provides. With all aspects of production under one roof, communication is more efficient, reducing the risk of errors and delays. This is crucial during pilot runs where time is of the essence.

Cost-Effective

Outsourcing production to a turnkey manufacturer can also be more cost-effective. It eliminates the need for businesses to invest in expensive equipment and hire additional staff. Furthermore, turnkey providers often have established relationships with suppliers, allowing them to negotiate better prices for materials.

Key Considerations for Pilot Runs

Understanding the Market

Before embarking on a pilot run, it’s crucial to understand the target market. Conduct thorough research to identify potential customers and their needs. This information will guide the design and production process, ensuring the final product meets consumer expectations.

Design and Prototyping

The design phase is critical in turnkey manufacturing. Work closely with your provider to develop a prototype that aligns with your vision. This stage may involve several iterations, so be prepared to provide feedback and make adjustments as needed.

Quality Control

Quality control is a vital aspect of turnkey manufacturing for pilot runs. Ensure your provider has robust quality assurance processes in place to catch any defects or issues early. This will save time and money in the long run and ensure the final product is of the highest standard.

Partnering with the Right Provider

Choosing the right turnkey manufacturer is crucial to the success of your pilot run. Look for a provider with a proven track record and experience in your industry. Don’t hesitate to ask for references and case studies to verify their capabilities.

Communication and Collaboration

Effective communication is key in any partnership. Establish clear lines of communication with your turnkey provider and ensure they understand your goals and expectations. Regular updates and feedback sessions will help keep the project on track.

Flexibility and Adaptability

The ability to adapt to changes is essential in any manufacturing process. Choose a turnkey provider who is flexible and willing to make adjustments as needed. This will ensure your pilot run is successful, even if unexpected challenges arise.

Conclusion

Turnkey manufacturing for pilot runs offers a host of benefits, from cost savings to improved efficiency. By choosing the right provider and focusing on key considerations, businesses can successfully bring their innovations to market. As the manufacturing landscape continues to evolve, those who embrace turnkey solutions will be well-positioned for success.

FAQs

What is the main advantage of turnkey manufacturing?

The main advantage of turnkey manufacturing is its ability to streamline the production process, saving time and resources.

How does turnkey manufacturing support pilot runs?

It provides a comprehensive approach, managing all aspects of production and allowing businesses to focus on refining their products.

What should I consider when choosing a turnkey provider?

Consider factors such as experience, communication, and flexibility when selecting a turnkey provider for your pilot run.

For more insights on turnkey procurement and DFX in manufacturing, visit our related articles.

Explore more about turnkey electronics manufacturing services and why it’s essential for modern businesses.