In today’s fast-paced world of manufacturing, businesses are constantly seeking ways to improve efficiency and reduce costs. One solution that has gained traction is turnkey manufacturing for high mix low volume production. This approach is particularly appealing to exporters and importers who need to adapt quickly to changing market demands.

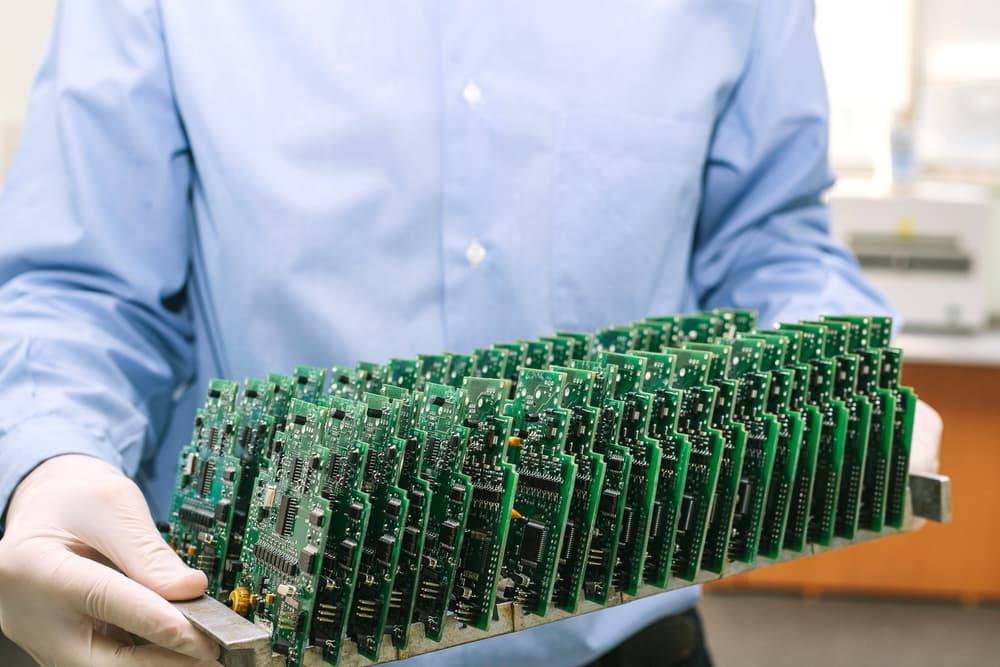

Turnkey manufacturing offers a streamlined process where a single provider manages all aspects of production, from sourcing materials to final assembly. This is especially beneficial in high mix low volume production, where businesses produce a variety of products in smaller quantities. The flexibility and efficiency of this model can provide a competitive edge in the global market.

Understanding Turnkey Manufacturing

Turnkey manufacturing is a comprehensive solution where a contractor handles all phases of production. This includes the design, procurement, manufacturing, and delivery of products. For businesses dealing with high mix low volume production, this means they can focus on their core competencies while leaving the complexities of manufacturing to the experts.

Benefits of High Mix Low Volume Production

Flexibility in Production

One of the main advantages of high mix low volume production is flexibility. Companies can adapt quickly to market changes without being tied down by large inventories. This agility is crucial in industries where consumer preferences and technological advancements evolve rapidly.

Cost Efficiency

While producing smaller quantities might seem costly, turnkey manufacturing can help reduce overheads. By outsourcing production, businesses can save on labor costs, equipment purchases, and maintenance. Moreover, the economies of scale achieved by manufacturers can result in lower per-unit costs.

Key Components of Turnkey Manufacturing

Supply Chain Management

An efficient supply chain is the backbone of turnkey manufacturing. By managing logistics, sourcing, and inventory, manufacturers ensure timely delivery of products. This is particularly important in high mix low volume production, where delays can disrupt the entire process. For more insights on supply chain management, visit the supply chain management article.

Quality Control

Maintaining high-quality standards is essential in manufacturing. Turnkey solutions often include rigorous quality control measures to ensure products meet specifications. This is vital for exporters and importers who must comply with international standards.

Challenges in Turnkey Manufacturing

Communication Barriers

Effective communication is crucial in turnkey manufacturing. Language barriers and time zone differences can pose challenges. Companies must establish clear lines of communication to ensure smooth operations.

Intellectual Property Concerns

When outsourcing manufacturing, businesses must protect their intellectual property. This involves drafting comprehensive contracts and ensuring the manufacturer adheres to confidentiality agreements.

Implementing Turnkey Solutions

Selecting the Right Partner

Choosing the right turnkey manufacturing partner is critical. Businesses should evaluate potential partners based on their expertise, reputation, and ability to deliver on time. For tips on selecting a partner, refer to the overview of turnkey solutions.

Integrating Technology

Technology plays a significant role in enhancing turnkey manufacturing efficiency. From automation to advanced software, companies must leverage technology to streamline processes and improve productivity.

Future of Turnkey Manufacturing

Emerging Trends

The future of turnkey manufacturing is promising, with trends such as digitalization, sustainability, and customization gaining momentum. Companies that embrace these trends will likely remain competitive in the global market.

Continued Growth

As more businesses recognize the benefits of turnkey solutions, the industry is expected to grow. This growth will lead to more innovations and improved services for exporters and importers.

Conclusion

In conclusion, turnkey manufacturing for high mix low volume production offers a viable solution for businesses looking to stay ahead in a competitive market. By leveraging the expertise of manufacturing partners, companies can focus on their core activities, reduce costs, and improve efficiency. For more information on how turnkey solutions can benefit your business, visit this external resource.

FAQs

What is turnkey manufacturing?

Turnkey manufacturing is a process where a single provider manages all aspects of production, from design to delivery.

Why choose high mix low volume production?

This approach offers flexibility and cost efficiency, allowing businesses to adapt to market changes quickly.

What are the challenges of turnkey manufacturing?

Challenges include communication barriers and protecting intellectual property.