In the dynamic world of defense, the need for precision, efficiency, and reliability cannot be overstated. With the increasing complexity of modern defense projects, turnkey manufacturing for defense applications has emerged as a pivotal approach. This method not only streamlines the production process but also ensures that defense products meet stringent quality standards. In this article, we delve into the nuances of turnkey manufacturing and its significance in the defense sector.

The Essence of Turnkey Manufacturing

Turnkey manufacturing refers to a comprehensive process where the manufacturer handles every aspect of productionfrom initial design to the final product. This approach is particularly beneficial in the defense sector, where precision and reliability are paramount. By entrusting a single entity with the entire manufacturing process, defense organizations can ensure consistency and quality across all production stages.

Benefits of Turnkey Manufacturing in Defense

The advantages of turnkey manufacturing in defense are manifold. Firstly, it significantly reduces the complexity of managing multiple suppliers and vendors. With a single point of contact, communication is streamlined, leading to faster decision-making and problem-solving. Additionally, turnkey manufacturing offers cost efficiencies by eliminating the need for intermediary suppliers. This, in turn, leads to reduced production costs and better resource allocation.

The Role of Technology in Turnkey Manufacturing

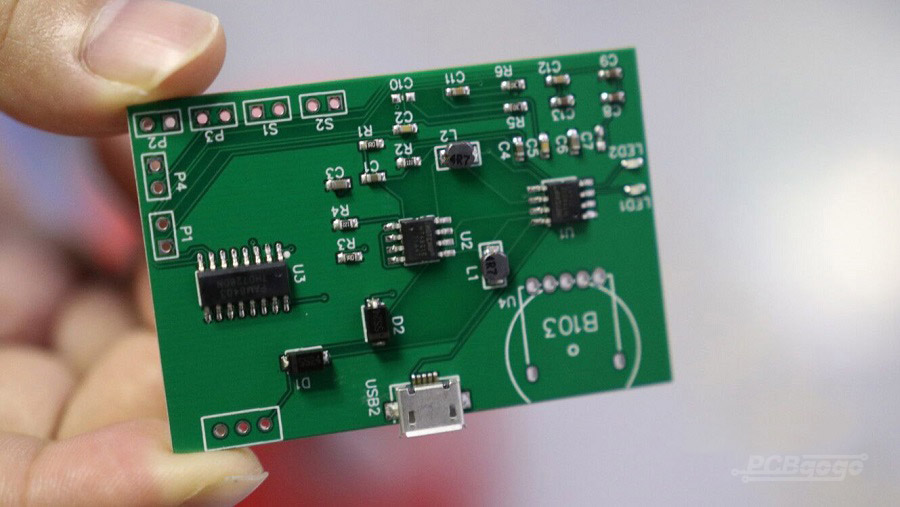

In today’s digital age, technology plays a crucial role in enhancing the efficiency and accuracy of turnkey manufacturing. Advanced technologies like AI, IoT, and robotics are integrated into the manufacturing process, ensuring precision and reliability. For instance, automated inspection systems ensure that each component meets the required standards, reducing the risk of defects in the final product. To learn more about automated inspection, visit this Automated Inspection article.

Quality Assurance in Turnkey Manufacturing

Quality assurance is a critical component of turnkey manufacturing for defense applications. Robust quality control mechanisms are in place to ensure that every product meets the highest standards. From the initial stages of design to the final product, stringent quality checks are conducted at every step. This ensures that the defense products are not only reliable but also capable of performing under the most challenging conditions.

Challenges and Solutions in Turnkey Manufacturing

While turnkey manufacturing offers numerous benefits, it also presents certain challenges. One of the primary challenges is maintaining consistency across various production stages. However, with the integration of advanced technologies and a focus on continuous improvement, these challenges can be effectively addressed. Moreover, regular audits and feedback mechanisms play a crucial role in enhancing the overall efficiency of the manufacturing process.

Case Studies: Successful Turnkey Manufacturing Projects

Several defense organizations have successfully implemented turnkey manufacturing to achieve remarkable results. For instance, a leading defense contractor utilized turnkey solutions to streamline the production of advanced radar systems. By doing so, they were able to reduce production time by 30% while maintaining the highest quality standards. Such success stories highlight the potential of turnkey manufacturing in revolutionizing the defense sector.

The Future of Turnkey Manufacturing in Defense

As the defense landscape continues to evolve, the role of turnkey manufacturing is set to become even more significant. With advancements in technology and an increasing emphasis on quality and efficiency, turnkey manufacturing will continue to play a pivotal role in shaping the future of defense production. By embracing this approach, defense organizations can ensure that they are well-equipped to meet the challenges of tomorrow.

Conclusion

In conclusion, turnkey manufacturing for defense applications offers a comprehensive solution to the complexities of defense production. By streamlining processes and ensuring quality, this approach not only enhances the efficiency of production but also ensures that defense products are reliable and of the highest quality. As the defense sector continues to evolve, turnkey manufacturing will remain an indispensable tool in ensuring that defense organizations are well-prepared for the future.

FAQ

What is turnkey manufacturing?

Turnkey manufacturing is a comprehensive production process where a single entity manages all aspects of production, from design to the final product.

How does turnkey manufacturing benefit the defense sector?

Turnkey manufacturing offers numerous benefits to the defense sector, including streamlined communication, cost efficiencies, and enhanced quality assurance.

What role does technology play in turnkey manufacturing?

Technology plays a crucial role in turnkey manufacturing by enhancing efficiency and accuracy through the integration of advanced technologies like AI, IoT, and robotics.