In today’s fast-paced digital world, the Internet of Things (IoT) is revolutionizing the way we interact with technology. The demand for smart, connected devices is skyrocketing, and businesses are eager to capitalize on this trend. However, bringing an IoT product to market can be a daunting task. This is where turnkey electronics manufacturing for IoT products becomes invaluable. By partnering with a reliable manufacturer, companies can streamline the production process and focus on what they do best: innovating and growing their business.

In this article, we’ll explore the ins and outs of turnkey electronics manufacturing, highlighting its benefits and offering insights for businesses looking to thrive in the IoT space.

What is Turnkey Electronics Manufacturing?

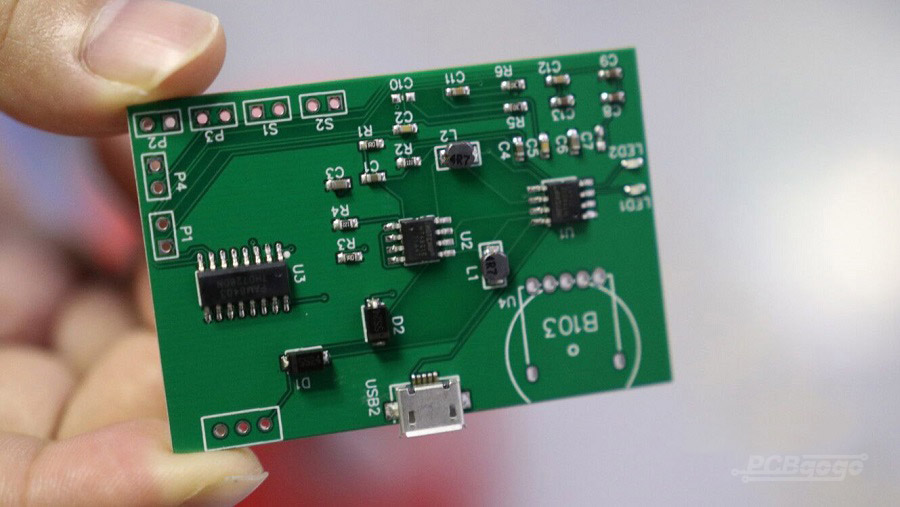

Turnkey electronics manufacturing involves outsourcing the entire production process to a specialized company. From design and prototyping to assembly and testing, the manufacturing partner handles it all. This comprehensive approach allows businesses to focus on their core competencies while ensuring a high-quality product.

Why Choose Turnkey Manufacturing for IoT Products?

There are several compelling reasons to opt for turnkey solutions when developing IoT products:

1. Expertise and Efficiency

Turnkey manufacturers possess the expertise and resources to efficiently produce complex IoT devices. Their experience in the field ensures that your product meets industry standards and consumer expectations. Moreover, the streamlined process reduces time-to-market, giving you a competitive edge.

2. Cost-Effectiveness

Outsourcing production to a turnkey provider can lead to significant cost savings. These companies often have established relationships with suppliers, enabling them to source components at lower prices. Additionally, the reduction in production time further decreases expenses.

3. Quality Assurance

Reputable turnkey manufacturers prioritize quality assurance. They implement rigorous testing procedures to identify and rectify any issues before products reach consumers. This commitment to quality minimizes the risk of defects and enhances customer satisfaction.

Key Considerations for Choosing a Turnkey Manufacturer

Selecting the right turnkey electronics manufacturing partner is crucial for the success of your IoT product. Here are some factors to consider:

1. Industry Experience

Look for a manufacturer with a proven track record in the IoT industry. Their experience will translate into a smoother production process and a higher-quality end product.

2. Customization Capabilities

Your IoT product may have unique requirements. Ensure that the manufacturer can accommodate customization requests to meet your specific needs.

3. Communication and Collaboration

Effective communication is vital for a successful partnership. Choose a manufacturer who values collaboration and keeps you informed throughout the production process.

Real-World Applications of IoT Products

IoT products are transforming various industries. Here are a few examples:

1. Smart Home Devices

From smart thermostats to voice-activated assistants, IoT is making homes more convenient and energy-efficient.

2. Healthcare Innovations

Wearable devices and remote monitoring systems are enhancing patient care and enabling better health management.

3. Industrial IoT Solutions

In manufacturing, IoT devices are optimizing production processes, reducing downtime, and improving safety.

Challenges in IoT Product Development

While the potential of IoT is vast, there are challenges to overcome:

1. Security Concerns

With increased connectivity comes the risk of cyber threats. Ensuring robust security measures is essential for protecting data and maintaining consumer trust.

2. Interoperability Issues

IoT devices often need to communicate with other systems. Ensuring compatibility and seamless integration can be complex.

Future Trends in IoT and Manufacturing

The future of IoT and manufacturing is promising:

1. 5G and IoT

The advent of 5G technology will enhance the capabilities of IoT devices, enabling faster and more reliable connections. This will open up new possibilities for innovation and growth.

2. Sustainable Manufacturing

As environmental concerns grow, manufacturers are adopting sustainable practices. This includes reducing waste, optimizing energy usage, and sourcing eco-friendly materials.

3. AI Integration

Artificial intelligence is playing a significant role in IoT development. AI-driven analytics are helping businesses make data-informed decisions and improve operational efficiency.

Conclusion

In conclusion, turnkey electronics manufacturing for IoT products offers numerous benefits for businesses looking to succeed in the IoT market. By leveraging the expertise and resources of a trusted partner, companies can streamline production, reduce costs, and deliver high-quality products to consumers. As the IoT landscape continues to evolve, staying informed about industry trends and challenges will be key to maintaining a competitive edge.

FAQs

What is turnkey electronics manufacturing?

Turnkey electronics manufacturing is a comprehensive service where a company handles every aspect of the production process, from design to assembly and testing.

Why choose turnkey manufacturing for IoT products?

Turnkey manufacturing offers expertise, cost-effectiveness, and quality assurance, making it an ideal choice for IoT product development.

What are the challenges in IoT product development?

Challenges include security concerns, interoperability issues, and the need for robust testing and quality assurance.

For more information on turnkey electronics manufacturing, visit Hi-Tek Quality.

For insights into IoT trends, check out our related articles on Environmental IoT, IoT Challenges, and IoT Firmware Control.