In todays fast-paced technological world, turnkey electronics manufacturing has become a crucial element for businesses looking to streamline their production processes. But what exactly does this term mean? In this article, we aim to provide a comprehensive understanding of turnkey electronics manufacturing, its benefits, and its impact on the industry.

What is Turnkey Electronics Manufacturing?

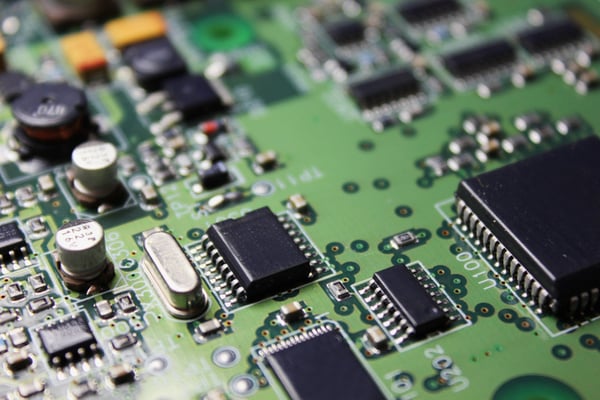

At its core, turnkey electronics manufacturing refers to a comprehensive approach where a single contractor handles all aspects of electronic product development. This includes everything from design, manufacturing, assembly, to testing and shipping. Companies opt for this service to reduce complexities and focus more on their core business activities.

Components of Turnkey Manufacturing

Key components of this process include:

- Design and Development: Creating prototypes and final product designs.

- Procurement: Sourcing all necessary components and materials.

- Assembly: Bringing together the components to create the final product.

- Testing: Ensuring the product meets all required standards and specifications.

- Shipping: Managing logistics to deliver the product to the end-user.

Advantages of Turnkey Electronics Manufacturing

The advantages of opting for turnkey solutions are numerous:

Cost Efficiency

By consolidating all production stages under one roof, companies can significantly reduce overhead costs. This is because turnkey manufacturing minimizes the need for multiple contractors, reducing the costs associated with coordination and logistics.

Time Savings

Time is a critical resource in any business. With turnkey solutions, companies benefit from reduced lead times as all processes are streamlined and handled by a single entity. This allows businesses to bring products to market faster and more efficiently.

Quality Assurance

Having a single contractor responsible for the entire production process ensures consistent quality across all stages. This reduces the risk of errors and defects, resulting in a superior end product. For further insight, you can explore PCB quality improvements through turnkey assembly.

Challenges in Turnkey Electronics Manufacturing

Despite its advantages, turnkey manufacturing does come with its own set of challenges:

Dependency on a Single Vendor

Relying on one contractor for all processes means that any issues with the vendor can impact the entire production cycle. This requires careful selection of a reputable and reliable manufacturing partner.

Initial Setup Costs

While turnkey solutions can save money in the long run, the initial setup costs can be higher as companies need to invest in aligning their processes with the contractors capabilities. However, the long-term benefits often outweigh these initial costs.

Impact on Various Industries

Turnkey solutions have far-reaching impacts across various sectors:

Consumer Electronics

The demand for rapid innovation and product releases in consumer electronics makes turnkey manufacturing an ideal choice for companies in this sector. It allows them to stay competitive by quickly adapting to market changes.

Automotive Industry

In the automotive industry, turnkey solutions facilitate the integration of advanced electronics into vehicles, supporting the push towards smarter and more efficient cars.

IoT Devices

The rise of IoT devices has increased the demand for turnkey manufacturing. It enables companies to efficiently produce complex devices with multiple functionalities. To understand this impact, you can read about 5G and IoT.

Choosing the Right Turnkey Partner

Selecting the right partner is crucial for leveraging the benefits of turnkey manufacturing. Considerations include:

Experience and Expertise

Choose a partner with a proven track record and expertise in your specific industry to ensure high-quality results.

Comprehensive Services

Opt for a partner that offers a full range of services, from design to shipping, to maximize efficiency and reduce overhead.

Technology and Innovation

The partner should be equipped with the latest technology and innovative solutions to support your product development and manufacturing needs.

Conclusion

Turnkey electronics manufacturing offers a streamlined, efficient, and cost-effective solution for companies across various industries. By understanding its components, benefits, and challenges, businesses can make informed decisions on how to best implement these solutions to achieve their goals. For more insights on this topic, you can refer to this external resource.

FAQs on Turnkey Electronics Manufacturing

What does turnkey mean in electronics manufacturing?

Turnkey in electronics manufacturing means a single contractor manages all stages of production from design to delivery.

How does turnkey manufacturing save time?

By streamlining processes under one contractor, companies reduce lead times and can bring products to market faster. Learn more about saving time with turnkey solutions.

Why is turnkey manufacturing beneficial for IoT devices?

Turnkey manufacturing supports the efficient production of complex IoT devices by integrating multiple functionalities seamlessly.