The transition from prototype to volume production is a critical phase in the manufacturing process, especially for exporters and importers who are keen on ensuring efficiency and quality. This transition involves moving from a small-scale production of prototypes to full-scale mass production. It is essential to get this transition right to avoid costly mistakes and ensure that the final product meets all quality standards and customer expectations.

Understanding the Prototype Phase

The prototype phase serves as the foundation for any successful product. During this stage, a prototype is developed to test the feasibility of the design and to identify any potential issues. This phase is crucial as it allows manufacturers to refine their designs and make necessary adjustments before moving on to mass production.

The Importance of Prototyping

Prototyping is vital because it helps in identifying design flaws early in the process. It allows designers and engineers to test the product in real-world conditions, ensuring that it functions as intended. This stage also provides an opportunity to gather feedback from stakeholders, which can be used to improve the design.

Challenges in Transitioning to Volume Production

Transitioning from prototype to volume production comes with its own set of challenges. One of the main challenges is ensuring that the quality of the product is maintained throughout the production process. This requires careful planning and coordination between different teams involved in the manufacturing process.

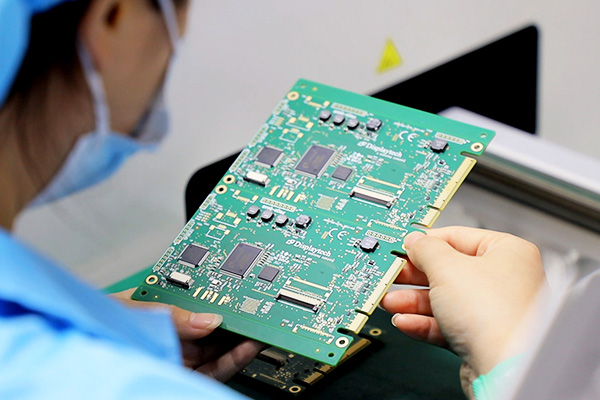

Quality Control Measures

Implementing stringent quality control measures is crucial during this transition. This involves setting up processes to monitor the quality of the products at every stage of production. It also includes conducting regular inspections and tests to ensure that the final product meets all required standards.

Strategies for a Successful Transition

There are several strategies that exporters and importers can employ to ensure a smooth transition from prototype to volume production. One of the most effective strategies is to adopt a phased approach. This involves gradually increasing production volumes while continuously monitoring and improving processes.

Collaborating with Experienced Partners

Another effective strategy is to collaborate with experienced partners who have expertise in large-scale manufacturing. These partners can provide valuable insights and support throughout the transition process, helping to identify potential issues and implement solutions.

Role of Technology in the Transition

Technology plays a significant role in facilitating the transition from prototype to volume production. Advanced manufacturing technologies, such as automation and robotics, can help streamline production processes and improve efficiency. Utilizing these technologies can also help reduce production costs and minimize errors.

Implementing Automation

Implementing automation in the production process can significantly enhance productivity. Automated systems can handle repetitive tasks with precision and speed, freeing up human resources for more complex tasks. This not only improves efficiency but also reduces the risk of human error.

Planning for Scale

Planning for scale is another important aspect of transitioning from prototype to volume production. This involves developing a comprehensive production plan that outlines the resources, processes, and timelines needed to achieve the desired production volumes.

Resource Management

Effective resource management is critical during this phase. This involves ensuring that all necessary resources, including materials, equipment, and labor, are available and utilized efficiently. It also includes forecasting future resource needs and making necessary adjustments to meet production demands.

Adapting to Market Changes

The manufacturing industry is dynamic, with market conditions constantly evolving. As such, it is essential for exporters and importers to adapt to these changes to remain competitive. This may involve adjusting production processes or exploring new technologies to meet changing market demands.

Staying Competitive

Staying competitive in the manufacturing industry requires a proactive approach to innovation and continuous improvement. This involves regularly reviewing and updating production processes to enhance efficiency and quality. It also includes investing in research and development to explore new opportunities and technologies.

Conclusion

The transition from prototype to volume production is a complex but crucial phase in the manufacturing process. By understanding the challenges and implementing effective strategies, exporters and importers can successfully navigate this transition and achieve their production goals. Embracing technology, collaborating with experienced partners, and adapting to market changes are key to ensuring a smooth and successful transition.

FAQs

What is the importance of transitioning from prototype to volume production?

The transition is important because it allows for the scaling of production while ensuring that the product meets quality standards and customer expectations.

How can technology aid in the transition process?

Technology, such as automation and robotics, can streamline production processes, improve efficiency, and reduce costs and errors.

Why is quality control essential during this transition?

Quality control measures ensure that the product maintains its quality throughout the production process, preventing costly mistakes and ensuring customer satisfaction.