In the fast-paced world of electronics, single source electronics manufacturing is a concept gaining significant traction. This approach simplifies the supply chain by relying on one manufacturer to handle all aspects of production. For exporters and importers, understanding this process can be a game-changer in managing costs and improving efficiency.

With the increasing complexity of electronics, the need for a streamlined process has never been more crucial. By adopting single source electronics manufacturing, businesses can ensure consistency in product quality and timely delivery, which are vital for maintaining competitive advantage in the global market.

What is Single Source Electronics Manufacturing?

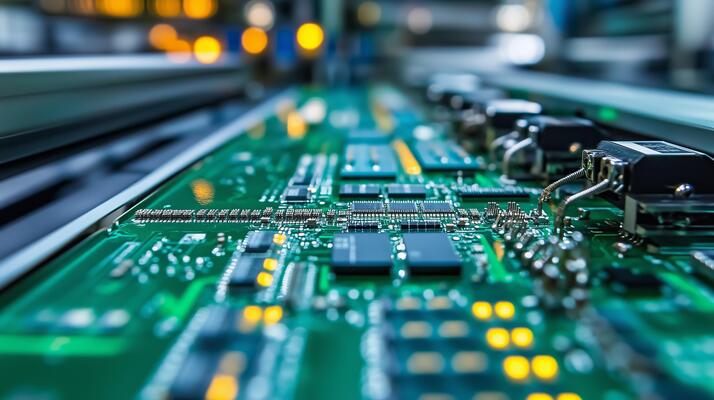

Single source electronics manufacturing refers to the practice of entrusting one manufacturer with all stages of electronics production, from design and prototyping to final assembly and testing. This method is particularly beneficial for exporters and importers who deal with complex supply chains and need reliable partners to manage their product lines efficiently.

Key Benefits of Single Source Manufacturing

- Improved Quality Control

- Cost Reduction

- Faster Time-to-Market

- Streamlined Communication

How Single Source Manufacturing Works

The process begins with a detailed consultation where the manufacturer understands the client’s specific needs. This is followed by designing the product, sourcing materials, and finally, the assembly and testing phase. Throughout the entire process, the manufacturer maintains close communication with the client to ensure alignment with their goals.

Why Choose Single Source Over Multiple Vendors?

Using a single source provides a unified approach to production, reducing the complexity and potential for errors that come with managing multiple vendors. It also fosters a stronger relationship with the manufacturer, who becomes a trusted partner invested in the success of the product. This partnership often leads to innovation and efficiency, as the manufacturer gains a deeper understanding of the client’s needs over time.

Impact on the Electronics Industry

The adoption of single source electronics manufacturing is reshaping the electronics industry. Companies that have made the switch report significant improvements in their supply chain efficiency and product quality. This trend is particularly evident in sectors such as consumer electronics, automotive, and telecommunications, where the demand for high-quality, reliable products is paramount.

Case Study: Successful Implementation

Consider a company that shifted from multiple vendors to a single source for their PCB assemblies. The transition resulted in a 30% reduction in lead times and a 20% decrease in production costs. By having a single point of contact, the company was able to streamline communications, leading to faster problem resolution and enhanced product quality.

Challenges in Adopting Single Source Manufacturing

While the benefits are clear, transitioning to a single source model can be challenging. It requires careful selection of a reliable manufacturer who can handle all aspects of production and align with the company’s strategic goals. Additionally, companies need to manage the risk of dependency on a single supplier, which can be mitigated through strong contracts and contingency planning.

How to Choose the Right Manufacturer

Choosing the right manufacturer involves evaluating their track record, technological capabilities, and financial stability. Companies should also consider the manufacturer’s ability to scale production and their expertise in the specific type of electronics being produced. A thorough vetting process can help ensure a successful partnership.

The Future of Single Source Electronics Manufacturing

As technology continues to advance, the role of single source electronics manufacturing is expected to grow. Emerging trends such as the Internet of Things (IoT) and smart devices are driving the demand for more integrated and efficient manufacturing solutions.

Integration with Digital Technologies

The integration of digital technologies, such as AI and machine learning, is further enhancing the capabilities of single source manufacturers. These technologies enable better data analysis and predictive maintenance, leading to improved efficiency and reduced downtime.

Frequently Asked Questions

What are the risks associated with single source manufacturing?

While single source manufacturing offers numerous benefits, it also comes with risks such as supplier dependency and potential supply chain disruptions. Companies can mitigate these risks by establishing strong contracts and having contingency plans in place.

How does single source manufacturing impact product quality?

By consolidating production under one manufacturer, companies can achieve greater consistency in product quality. The manufacturer can implement standardized processes and maintain rigorous quality control throughout the production cycle.

Is single source manufacturing suitable for all types of electronics?

While single source manufacturing is beneficial for many types of electronics, it may not be suitable for all. Companies need to assess their specific needs and the complexity of their products to determine if this approach is the right fit.

For more insights on how turnkey manufacturing impacts the industry, check out this [overview of turnkey contract manufacturing](https://blinternationalcompany.com/blog/overview-of-turnkey-contract-manufacturing/) and explore its advantages here.