In the world of electronics manufacturing, the concept of turnkey solutions has gained significant traction. While the benefits of these solutions are widely acknowledged, it is crucial to delve into the risks of turnkey electronics manufacturing. Understanding these potential pitfalls is essential for exporters and importers, who rely heavily on these services to streamline their production processes.

The journey of turnkey electronics manufacturing may seem like a smooth ride, but beneath the surface lie various challenges that can impact the outcome. This article explores these risks in detail, shedding light on the aspects that require careful consideration.

Understanding Turnkey Electronics Manufacturing

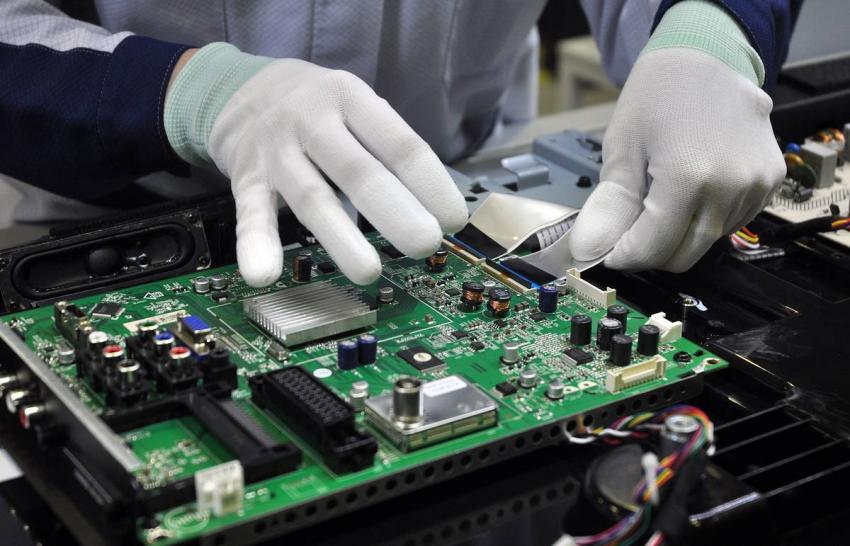

Turnkey electronics manufacturing refers to a comprehensive approach where a single entity handles all aspects of the production process, from design to delivery. While it offers convenience and efficiency, it also presents certain risks that must be addressed.

Quality Control Issues

One of the primary risks of turnkey electronics manufacturing is related to quality control. When outsourcing the entire manufacturing process, there is a possibility of losing direct oversight of quality standards. This can lead to inconsistencies in product quality, which can have detrimental effects on the end-user experience.

Supplier Reliability Concerns

In a turnkey setup, the reliability of suppliers is crucial. Any disruptions in the supply chain can cause delays, impacting delivery timelines and customer satisfaction. It is essential to thoroughly vet suppliers and establish strong relationships to mitigate this risk.

Communication Challenges

Effective communication is vital in turnkey electronics manufacturing. Misunderstandings between the manufacturer and client can lead to errors in the final product. Clear and consistent communication channels must be established to avoid such mishaps.

Cost Implications

While turnkey solutions are designed to be cost-effective, they can sometimes lead to unexpected expenses. It is important to understand the cost structure and potential hidden costs associated with these services.

Hidden Costs in Turnkey Solutions

Unexpected costs can arise from various sources, such as additional fees for expedited services or unforeseen complications during production. It is crucial to have a transparent agreement in place to avoid any financial surprises.

Impact on Budget Planning

Budget planning is an essential aspect of any manufacturing process. Turnkey manufacturing can sometimes make it challenging to allocate funds accurately due to fluctuating expenses.

Intellectual Property Risks

Protecting intellectual property is a significant concern in the electronics industry. When outsourcing to a turnkey provider, there is a risk of potential breaches in confidentiality, leading to unauthorized use of proprietary information.

Data Security Concerns

Ensuring data security is paramount in turnkey electronics manufacturing. A breach can have severe consequences, not only for the manufacturer but also for their clients. Implementing robust security measures is essential to safeguard sensitive information.

Legal Implications

Legal issues can arise if there are disputes over intellectual property rights. It is crucial to have legal agreements in place to protect both parties involved in the manufacturing process.

Dependency on a Single Provider

While relying on a single turnkey provider offers convenience, it also poses certain risks. The dependency on one entity can lead to potential disruptions if they face operational challenges.

Operational Risks in Turnkey Manufacturing

If the turnkey provider encounters operational difficulties, it can affect the entire production process, causing delays and impacting customer satisfaction.

Mitigating Dependency Risks

To mitigate dependency risks, it is advisable to have contingency plans in place, such as maintaining relationships with multiple providers or having an in-house backup strategy.

Conclusion

In the realm of turnkey electronics manufacturing, understanding the associated risks is crucial for exporters and importers. While these solutions offer numerous advantages, addressing potential challenges is essential to ensure a seamless production process. By acknowledging and mitigating these risks, businesses can leverage turnkey solutions effectively, paving the way for growth and success.

FAQs

What are turnkey electronics manufacturing solutions?

Turnkey electronics manufacturing solutions involve a comprehensive approach where a single entity manages all aspects of the production process, from design and procurement to assembly and delivery.

How can businesses mitigate quality control risks in turnkey manufacturing?

Businesses can mitigate quality control risks by establishing clear quality standards, conducting regular inspections, and maintaining effective communication with the turnkey provider.

Why is intellectual property protection important in turnkey electronics manufacturing?

Protecting intellectual property is crucial to prevent unauthorized use of proprietary information, which can have significant legal and financial implications for businesses.