In the ever-evolving world of electronics, the demand for more complex and compact solutions has led to the rise of rigid flex PCB turnkey assembly as a preferred choice. Understanding the significance and the process of this assembly is crucial for both exporters and importers aiming to stay competitive in the global market.

What is Rigid Flex PCB Turnkey Assembly?

A rigid flex PCB is a hybrid of flexible and rigid circuits, offering the advantages of both. The term ‘turnkey’ implies a comprehensive service where the manufacturer manages the entire process from design to delivery. This method simplifies the production process, reduces costs, and minimizes errors.

Benefits of Rigid Flex PCBs

Space and Weight Reduction

By combining rigid and flexible PCBs, you can significantly reduce space and weight. This is ideal for devices where these factors are crucial, such as in aerospace or medical applications.

Increased Reliability

The integration of rigid and flexible circuits allows for fewer connection points, which reduces the risk of connection failures and increases the overall reliability of the device.

Design Flexibility

Rigid flex PCBs provide enhanced design flexibility, allowing for more complex and intricate designs. This is beneficial for creating innovative products and meeting specific design requirements.

Key Components of a Turnkey Assembly

Design and Prototyping

The process begins with design and prototyping. This crucial step ensures that the final product meets all specifications and functions as intended. For more insight on this phase, visit Electronics Prototyping vs Mass Production.

Component Procurement

In a turnkey assembly, the manufacturer is responsible for sourcing all components. This not only ensures quality control but also simplifies logistics for the client. Learn more about procurement strategies at Turnkey Procurement.

Assembly Process

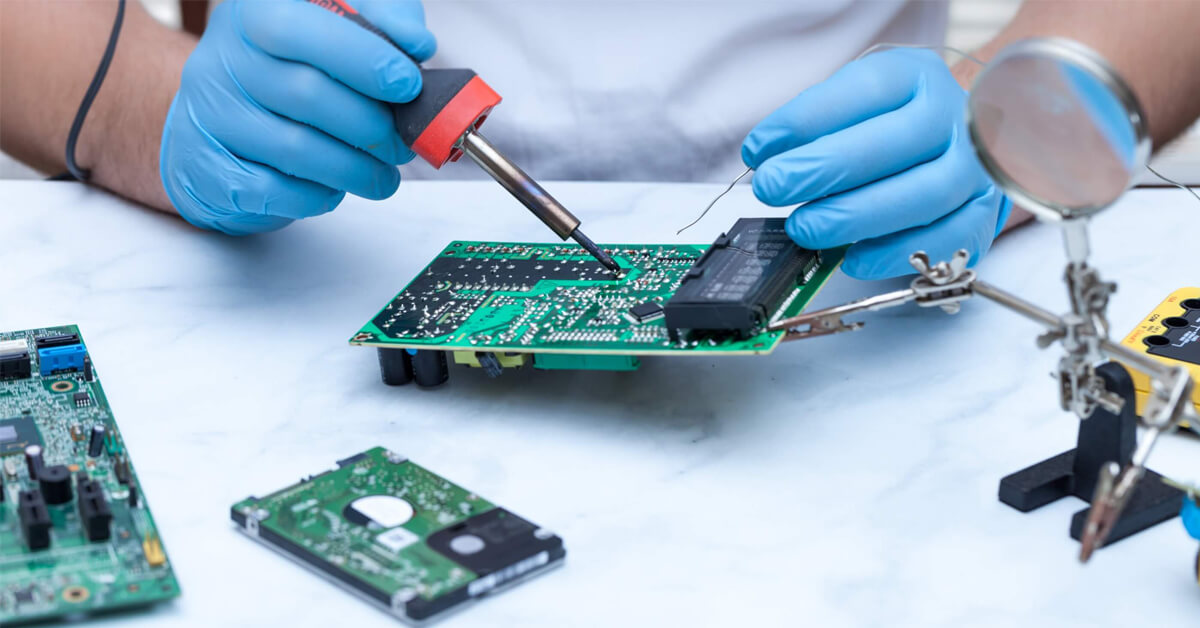

The assembly process involves the integration of rigid and flexible circuits, requiring precision and expertise to ensure proper functionality and durability.

Testing and Quality Assurance

Thorough testing is conducted to ensure that the final product meets all quality standards and performs reliably in real-world conditions.

Applications of Rigid Flex PCBs

Consumer Electronics

From smartphones to wearable devices, rigid flex PCBs are essential in creating compact and efficient consumer electronics.

Aerospace and Defense

In aerospace and defense, the reliability and space-saving benefits of rigid flex PCBs are critical in the design and function of advanced systems.

Medical Devices

Medical devices require high reliability and miniaturization, making rigid flex PCBs an ideal choice for various applications.

Challenges in Rigid Flex PCB Turnkey Assembly

Design Complexity

The intricate design of rigid flex PCBs can pose challenges, requiring expert knowledge and advanced software tools.

Manufacturing Costs

While turnkey assembly can reduce overall costs, the initial expenses for design and materials can be higher compared to traditional PCBs.

Material Selection

Choosing the right materials that can withstand various environmental conditions is crucial for the longevity and performance of the device.

The Future of Rigid Flex PCB Turnkey Assembly

The demand for more sophisticated electronic devices is driving the growth of rigid flex PCB turnkey assembly. As technology advances, we can expect even more applications and innovations in this field.

FAQs

What is the main advantage of using rigid flex PCBs?

The main advantage is the ability to reduce space and weight, making them ideal for compact and lightweight electronic devices.

How does turnkey assembly benefit manufacturers?

Turnkey assembly simplifies the production process by managing all aspects from design to delivery, reducing costs and errors.

Can rigid flex PCBs be used in all electronic devices?

While they are versatile, rigid flex PCBs are particularly beneficial in applications where space, weight, and reliability are critical factors.

For more information on the differences between turnkey and other assembly methods, you may find this article helpful: Differences between Turnkey PCB and Consignment PCB Assembly.