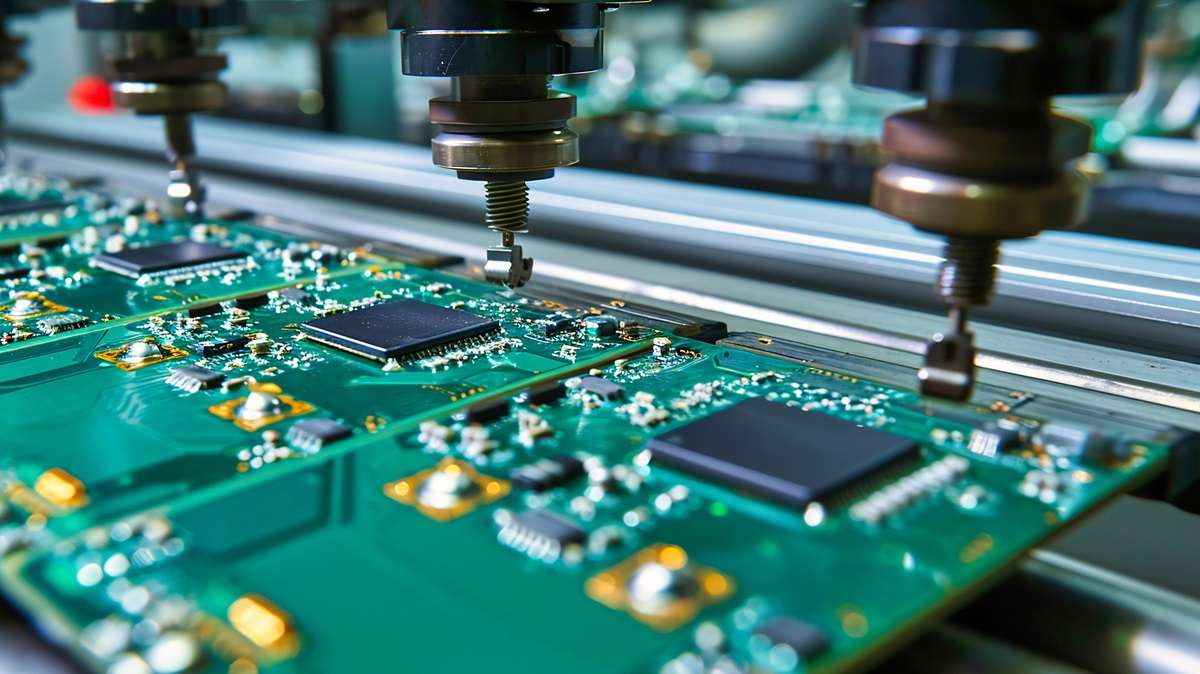

In today’s fast-paced electronics industry, rapid prototyping with turnkey electronics manufacturing has become a game-changer. This innovative approach allows companies to bring their ideas to life quickly and efficiently. By combining rapid prototyping with turnkey solutions, businesses can streamline their processes, reduce costs, and improve time-to-market. In this article, we’ll explore how this method works and why it’s beneficial for companies involved in electronics manufacturing.

Understanding Rapid Prototyping

At its core, rapid prototyping is a technique used to quickly fabricate a scale model of a physical part or assembly. This process often employs 3D printing technology to create prototypes that can be tested and refined before moving into full-scale production. The primary advantage of rapid prototyping is its ability to identify design flaws early in the development process, preventing costly errors down the line.

What is Turnkey Electronics Manufacturing?

Turnkey electronics manufacturing refers to a comprehensive service where a single company manages all aspects of the production process. From design and prototyping to assembly and testing, a turnkey provider handles every step, ensuring a seamless transition from concept to finished product. This holistic approach is particularly beneficial for companies looking to minimize risks, reduce costs, and improve efficiency.

The Benefits of Combining Rapid Prototyping with Turnkey Solutions

Integrating rapid prototyping with turnkey solutions offers several advantages:

1. Speed and Efficiency

By leveraging the expertise of a turnkey provider, businesses can significantly reduce the time it takes to develop and manufacture a product. This accelerated timeline allows companies to respond quickly to market demands and stay ahead of the competition.

2. Cost-Effective Solutions

Outsourcing the entire production process to a single provider can be more cost-effective than managing multiple vendors. Turnkey manufacturers often have established relationships with suppliers, allowing them to secure materials at lower prices and pass the savings onto their clients.

3. Improved Quality and Consistency

A turnkey approach ensures that all aspects of production are overseen by a single entity, leading to improved quality control and consistency. With enhanced quality assurance, companies can deliver reliable products that meet industry standards.

4. Reduced Risk

By consolidating the production process, turnkey solutions help mitigate risks associated with supply chain disruptions, design errors, and production delays. This approach allows businesses to focus on their core competencies while leaving the complexities of manufacturing to the experts.

How Rapid Prototyping Enhances Product Development

Rapid prototyping plays a crucial role in product development by allowing companies to iterate and refine their designs quickly. Through ongoing testing and feedback, businesses can identify potential issues early in the process and make necessary adjustments before committing to full-scale production. This iterative approach leads to higher-quality products and a greater likelihood of success in the market.

Key Considerations for Choosing a Turnkey Provider

When selecting a turnkey provider, it’s essential to consider several factors:

1. Experience and Expertise

Look for a provider with a proven track record in electronics manufacturing. Their experience and expertise can be invaluable in guiding your project from concept to completion.

2. Range of Services

Choose a provider that offers a comprehensive range of services, including rapid prototyping, design, assembly, and testing. This ensures a seamless transition between each stage of the production process.

3. Quality Assurance

Ensure that the provider has robust quality assurance processes in place to guarantee the reliability and performance of your products.

4. Communication and Collaboration

Effective communication is crucial when working with a turnkey provider. Choose a company that values collaboration and keeps you informed throughout the entire process.

The Future of Rapid Prototyping and Turnkey Manufacturing

As technology continues to evolve, the combination of rapid prototyping and turnkey manufacturing will become even more integral to the electronics industry. With advances in 3D printing, automation, and artificial intelligence, companies can expect even greater efficiencies and innovations in the production process.

Conclusion

In conclusion, rapid prototyping with turnkey electronics manufacturing offers a powerful solution for companies looking to innovate and compete in the dynamic world of electronics. By leveraging the benefits of both approaches, businesses can bring their ideas to life quickly, cost-effectively, and with a high degree of quality and consistency.

FAQ

1. What is rapid prototyping?

Rapid prototyping is a technique used to quickly create a scale model of a part or assembly using 3D printing technology.

2. How does turnkey manufacturing benefit companies?

Turnkey manufacturing provides a comprehensive solution by managing all aspects of production, leading to reduced costs, improved quality, and faster time-to-market.

3. Why is quality assurance important in turnkey solutions?

Quality assurance ensures that products meet industry standards and perform reliably, enhancing customer satisfaction and reducing the risk of defects.