Understanding how turnkey PCB assembly works is crucial for those involved in the import and export of electronics. This comprehensive solution streamlines the manufacturing process, offering numerous benefits for businesses looking to bring their products to market efficiently. In this article, we will delve into the various aspects of turnkey PCB assembly and explore why it has become a preferred choice for many in the industry.

What is Turnkey PCB Assembly?

Turnkey PCB assembly refers to a service where a single provider handles all aspects of the printed circuit board (PCB) manufacturing process. This includes everything from procurement of components, PCB fabrication, assembly, testing, and even shipping. By opting for a turnkey solution, businesses can alleviate the complexities of coordinating multiple suppliers and focus on their core operations.

The Process of Turnkey PCB Assembly

1. Design and Prototyping

The first step in how turnkey PCB assembly works is the design and prototyping phase. Here, engineers create a design based on the specifications provided by the client. This is a critical stage as it lays the foundation for subsequent processes.

2. Component Sourcing

Once the design is finalized, the turnkey provider sources all necessary components. This involves selecting high-quality parts that meet the requirements and ensuring their availability for the assembly process.

3. PCB Fabrication

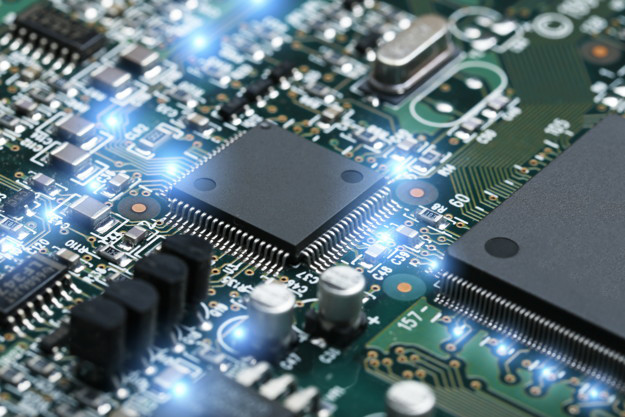

This step involves the actual creation of the PCB. The turnkey provider handles the fabrication process, ensuring that the boards are produced with precision and adhere to industry standards.

4. Assembly

During assembly, components are placed on the fabricated PCBs. This is done using automated machinery to ensure accuracy and efficiency. The turnkey provider oversees this process to maintain quality control.

5. Testing and Quality Assurance

After assembly, the PCBs undergo rigorous testing to ensure functionality and reliability. Quality assurance is a vital aspect of turnkey PCB assembly, as it verifies that the final product meets the required standards.

Benefits of Turnkey PCB Assembly

Cost-Effectiveness

By consolidating the entire manufacturing process under one roof, turnkey solutions often result in cost savings. This is achieved through bulk purchasing of components and reduced logistical expenses.

Time Efficiency

With turnkey assembly, the time from design to final product is significantly shortened. This allows businesses to bring their products to market faster, gaining a competitive edge.

Quality Assurance

Turnkey providers maintain strict quality control throughout the process, ensuring a high level of reliability in the final product. This is particularly important for exporters and importers dealing with international markets.

Choosing the Right Turnkey Provider

When selecting a turnkey PCB assembly provider, it is essential to consider factors such as experience, reputation, and the ability to meet specific requirements. A reliable provider will offer transparency and support throughout the process, ensuring successful outcomes.

Conclusion

The growing demand for turnkey PCB assembly solutions highlights their importance in the electronics industry. By understanding how turnkey PCB assembly works, importers and exporters can make informed decisions that enhance their operational efficiency. For further insights into the benefits of choosing a single facility for turnkey manufacturing, you can read more on the Proto Express blog.

FAQs

What is the role of a turnkey provider?

A turnkey provider manages the entire PCB manufacturing process, from design to delivery, ensuring efficiency and quality.

How does turnkey assembly save time?

By handling all aspects under one roof, turnkey assembly reduces the time required for coordination and logistics, speeding up the entire process.

Why is quality assurance important in turnkey assembly?

Quality assurance ensures that the final product meets industry standards and customer expectations, which is crucial for maintaining trust in the global market.