In today’s fast-paced world of electronics manufacturing, maintaining high quality standards is crucial. One of the most efficient ways to achieve this is through turnkey PCB assembly. This process streamlines production, improves consistency, and enhances the overall quality of electronic products. Let’s delve into how this innovative approach to manufacturing can revolutionize the industry.

Understanding Turnkey PCB Assembly

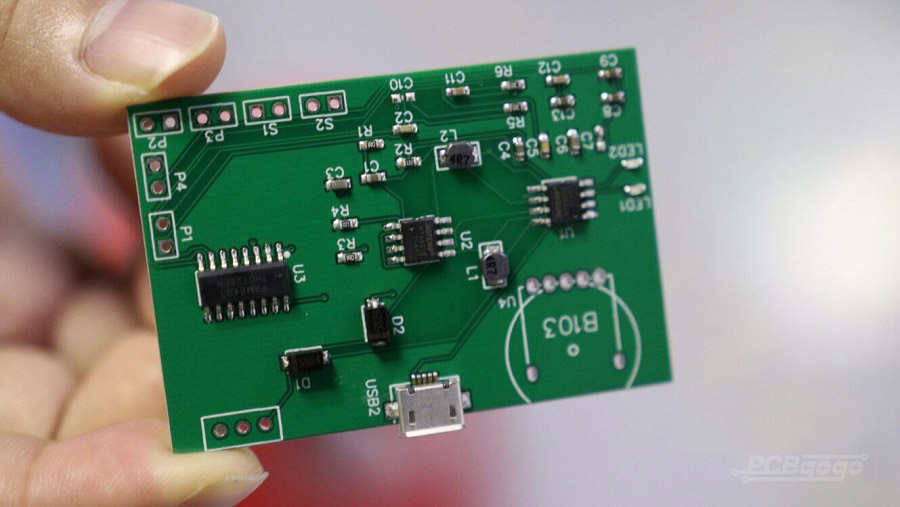

The concept of turnkey PCB assembly involves outsourcing the entire process of manufacturing printed circuit boards (PCBs) to a single service provider. This includes everything from sourcing components to assembling the final product. By centralizing these tasks, manufacturers can focus on design and innovation, leaving the complexities of production to experts.

Benefits of Turnkey PCB Assembly

Cost-Effectiveness

One of the primary advantages of turnkey PCB assembly is its cost-effectiveness. By consolidating all production processes under one roof, companies can significantly reduce overhead costs. This approach also minimizes the risk of errors and delays, leading to further savings.

Enhanced Quality Control

Quality control is a critical aspect of electronics manufacturing. With turnkey PCB assembly, comprehensive quality checks are integrated into every stage of production. This ensures that any potential issues are identified and addressed promptly, resulting in superior end products.

Faster Time to Market

In the competitive world of electronics, speed is of the essence. By using turnkey PCB assembly, manufacturers can significantly reduce the time it takes to bring a product to market. This is achieved through streamlined processes and efficient communication between teams.

Why Quality Matters in Electronics

Quality is a key differentiator in the electronics industry. High-quality products not only enhance customer satisfaction but also reduce returns and warranty claims. By investing in turnkey PCB assembly, companies can ensure that their products meet the highest standards of excellence.

How Turnkey PCB Assembly Enhances Quality

Consistency in Production

Consistency is a hallmark of quality manufacturing. With turnkey PCB assembly, production processes are standardized, ensuring that every unit meets the same high standards. This reduces variability and enhances reliability.

Expertise and Experience

Partnering with a turnkey PCB assembly provider brings access to a wealth of expertise and experience. These providers have specialized knowledge in PCB manufacturing, which translates into higher quality products and innovative solutions.

Advanced Technology

Many turnkey PCB assembly providers invest in cutting-edge technology to enhance production efficiency and quality. This includes automated assembly lines, advanced testing equipment, and sophisticated design software.

Challenges and Considerations

While turnkey PCB assembly offers numerous benefits, there are challenges to consider. These include finding a reliable partner, managing communication, and ensuring alignment with company goals. However, with careful planning and due diligence, these challenges can be effectively managed.

Case Studies: Success Stories

Several companies have successfully leveraged turnkey PCB assembly to improve their product quality. For instance, a leading electronics firm reduced its defect rate by 30% after transitioning to a turnkey model. Such success stories highlight the transformative potential of this approach.

Future Trends in Turnkey PCB Assembly

The future of turnkey PCB assembly looks promising, with advancements in AI, IoT, and automation set to further enhance quality and efficiency. These technologies will enable more precise manufacturing and faster production cycles.

Frequently Asked Questions

What is turnkey PCB assembly?

Turnkey PCB assembly is a comprehensive service where a single provider handles all aspects of PCB manufacturing, from component sourcing to final assembly.

How does turnkey PCB assembly improve product quality?

By centralizing production processes, turnkey PCB assembly ensures consistent quality control, reduces errors, and enhances overall product reliability.

What are the cost benefits of turnkey PCB assembly?

Turnkey PCB assembly reduces overhead costs by streamlining production processes and minimizing the risk of errors and delays.

For more insights on the benefits of turnkey PCB assembly, visit ProtoExpress.

To further explore the world of electronics manufacturing, you can visit this article on 5G impact on IoT and another insightful piece on open innovation in IoT.