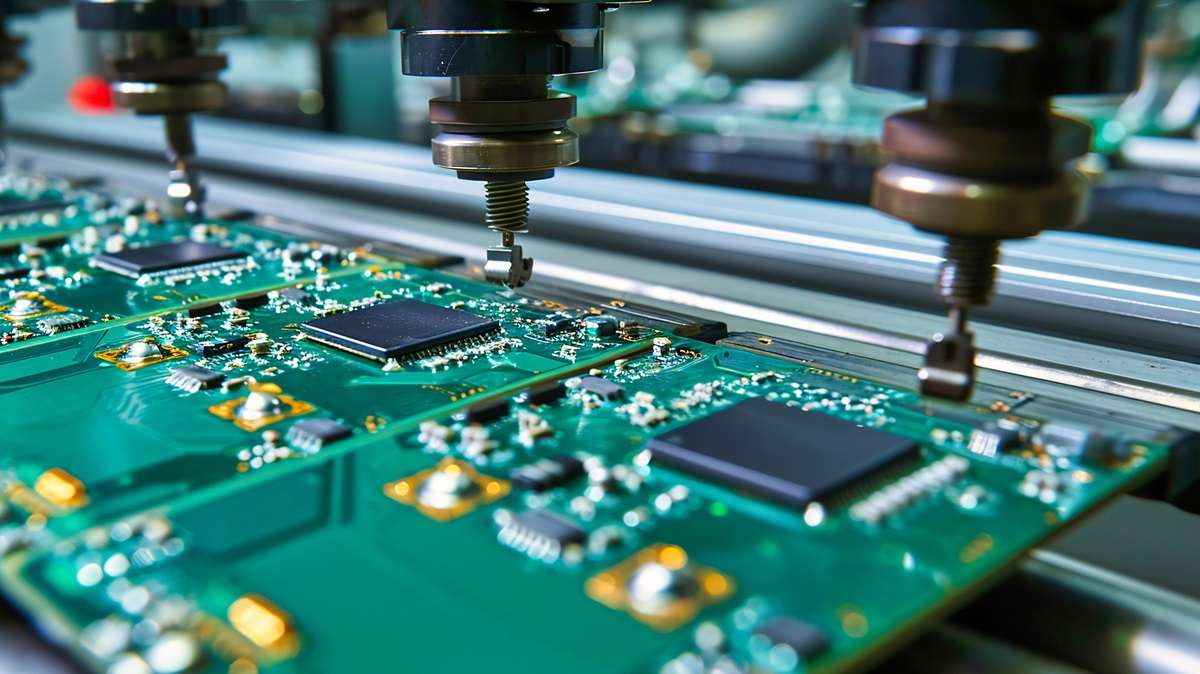

In the dynamic world of manufacturing, understanding how turnkey manufacturers manage procurement is crucial for both exporters and importers. Procurement is the backbone of any manufacturing process, and in the context of turnkey solutions, it plays a pivotal role in ensuring efficiency, quality, and cost-effectiveness. This article delves into the intricacies of procurement management by turnkey manufacturers, offering insights that can benefit businesses across the globe.

The Importance of Procurement in Turnkey Manufacturing

Procurement is more than just purchasing raw materials; it’s about acquiring the right components at the right time and cost. In turnkey manufacturing, where the manufacturer is responsible for the entire production process, effective procurement is essential to meet project timelines and quality standards. A well-managed procurement process ensures that all components are available when needed, reducing downtime and increasing productivity.

Key Strategies in Procurement Management

Turnkey manufacturers employ several strategies to manage procurement effectively:

- Supplier Relationships: Building strong relationships with suppliers is vital. It ensures a reliable supply of high-quality components and fosters collaboration for better pricing and terms.

- Cost Management: Efficient procurement focuses on cost management to maintain competitive pricing without compromising on quality.

- Technology Utilization: Leveraging technology in procurement processes, such as using software for inventory management and supplier communication, enhances efficiency.

Challenges Faced and Overcome

Managing procurement is not without challenges. Turnkey manufacturers often face issues such as fluctuating material costs, supply chain disruptions, and quality control. However, through strategic planning and risk management, these challenges can be mitigated. For instance, having multiple suppliers can reduce dependency on a single source, thus minimizing risks associated with supply chain disruptions.

How Turnkey Solutions Reduce Supply Chain Risks

One significant advantage of turnkey manufacturing is its ability to reduce supply chain risks. By handling the entire production process, turnkey manufacturers can streamline operations, ensuring that potential risks are identified and addressed early in the procurement phase. This not only safeguards the production schedule but also enhances the overall quality of the final product.

Quality Assurance in Procurement

Quality assurance is a critical component of procurement management. Turnkey manufacturers implement stringent quality checks at every stage of procurement to ensure that the components meet the required standards. This involves regular supplier audits and inspections, as well as using advanced quality management systems to monitor compliance.

Technological Advancements in Turnkey Procurement

The integration of technology in procurement processes has revolutionized how turnkey manufacturers operate. With advancements such as AI and machine learning, manufacturers can predict demand more accurately, optimize inventory levels, and identify potential supply chain disruptions before they occur. This proactive approach not only improves efficiency but also contributes to cost savings.

Case Study: Successful Procurement Management

A case study of a leading turnkey manufacturer illustrates the success of effective procurement management. By adopting a holistic approach to procurement, the company was able to reduce production costs by 15% while improving product quality. This was achieved through strategic supplier partnerships, investment in technology, and a focus on continuous improvement.

The Role of Communication in Procurement

Effective communication is the cornerstone of successful procurement management. Turnkey manufacturers prioritize open and transparent communication with suppliers, ensuring that expectations are clear and any issues are promptly addressed. This collaborative approach fosters trust and strengthens supplier relationships, leading to better procurement outcomes.

Environmental Considerations in Procurement

As sustainability becomes increasingly important, turnkey manufacturers are incorporating environmental considerations into their procurement processes. This involves selecting suppliers who adhere to sustainable practices and opting for eco-friendly materials. By doing so, manufacturers not only meet regulatory requirements but also contribute to a more sustainable future.

Future Trends in Turnkey Procurement

The future of procurement in turnkey manufacturing is promising, with several trends on the horizon. These include the increasing use of blockchain technology for enhanced transparency, the adoption of more sustainable procurement practices, and the continued integration of AI and data analytics for improved decision-making.

Conclusion: The Path Forward

Understanding how turnkey manufacturers manage procurement provides valuable insights into the strategies and practices that drive success in the manufacturing industry. By focusing on supplier relationships, leveraging technology, and prioritizing quality and sustainability, turnkey manufacturers can navigate the complexities of procurement with confidence. As the industry evolves, staying informed about the latest trends and innovations will be key to maintaining a competitive edge.

FAQs

What is turnkey manufacturing?

Turnkey manufacturing refers to a comprehensive production process where the manufacturer manages all aspects, from procurement to final product delivery. This approach ensures efficiency and quality throughout the production cycle.

How do turnkey manufacturers ensure quality in procurement?

Turnkey manufacturers implement stringent quality control measures, including supplier audits and inspections, to ensure that all components meet the required standards.

What technological advancements are impacting procurement?

Technological advancements such as AI, machine learning, and blockchain are revolutionizing procurement by improving demand forecasting, enhancing transparency, and optimizing inventory management.