In today’s fast-paced world, businesses are constantly seeking ways to ensure the smooth flow of their operations. A pressing issue they face is the shortage of components, which can significantly disrupt production. Many companies are turning to turnkey solutions to mitigate these challenges. Understanding how turnkey companies handle component shortages can provide valuable insights into maintaining seamless supply chains.

The Role of Turnkey Solutions in Modern Manufacturing

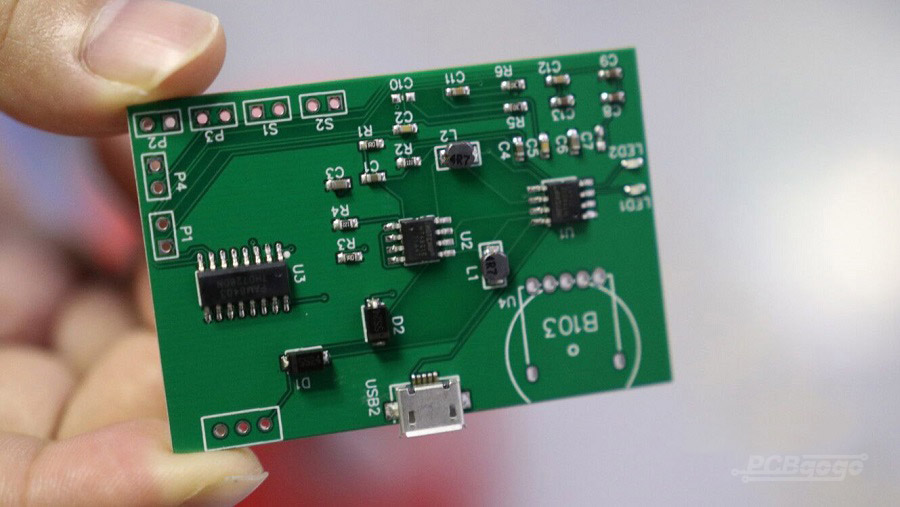

Turnkey companies offer comprehensive services that encompass every stage of production, from design to delivery. By managing the entire process, they can swiftly address any disruptions, such as component shortages.

Understanding Component Shortages

Component shortages occur when the demand for parts surpasses supply. This can be due to various factors, including geopolitical tensions, natural disasters, or manufacturing disruptions. For businesses relying on these components, shortages can lead to delays and increased costs.

How Turnkey Companies Mitigate Risks

Turnkey companies employ several strategies to handle component shortages. These include diversifying their supplier base, maintaining inventory buffers, and using advanced forecasting tools to predict potential shortages.

Diversifying the Supplier Base

One of the foremost methods turnkey companies use is diversifying their supplier base. By sourcing components from multiple suppliers, they reduce dependency on a single source, thus minimizing risks associated with shortages.

Maintaining Inventory Buffers

Inventory buffers act as a safety net during component shortages. By keeping a reserve stock of critical components, turnkey companies can continue production seamlessly, even when primary sources face disruptions.

Advanced Forecasting Tools

Using advanced forecasting tools, turnkey companies can predict potential shortages before they occur. These tools analyze market trends, geopolitical events, and other factors to provide accurate predictions.

Collaborative Relationships with Suppliers

Building strong, collaborative relationships with suppliers is crucial. By working closely with suppliers, turnkey providers can secure priority access to components during times of scarcity.

Embracing Technological Solutions

Technology plays a pivotal role in managing component shortages. Automated systems and real-time tracking allow turnkey companies to monitor supply chains closely and react swiftly to any disruptions.

Planning for the Future

Looking ahead, turnkey companies are investing in sustainable solutions to address potential shortages. This includes exploring alternative materials and investing in local manufacturing to reduce reliance on global supply chains.

Implementing Sustainable Practices

By implementing sustainable practices, such as recycling and reusing components, turnkey companies can minimize their environmental impact and ensure a steady supply of necessary parts.

The Importance of Communication

Effective communication is essential. Keeping stakeholders informed about potential shortages and the measures being taken ensures transparency and builds trust.

Real-world Examples of Success

Several companies have successfully navigated component shortages by adopting turnkey solutions. For instance, a leading automotive manufacturer partnered with a turnkey provider to secure components, ensuring uninterrupted production during a global shortage.

Conclusion: The Path Forward

In conclusion, the ability of turnkey companies to handle component shortages effectively is a testament to their strategic planning and innovative approaches. By leveraging technology, diversifying suppliers, and maintaining robust communication with stakeholders, they can ensure uninterrupted production, even in challenging times.

For more insights into how turnkey companies can enhance your business operations, visit Turnkey Manufacturing for Automotive Electronics and What is Turnkey PCB Assembly?.

FAQs

1. What are the main challenges of component shortages?

Component shortages can lead to production delays, increased costs, and a potential loss of market share if not addressed promptly.

2. How do turnkey companies help in reducing overhead costs?

Turnkey companies streamline the production process, which can lead to significant overhead cost reductions. Learn more about this in How Turnkey Helps Reduce Overhead.

3. What role does technology play in managing component shortages?

Technology allows for real-time monitoring and advanced forecasting, enabling turnkey companies to react quickly to potential shortages.