Electrical noise is a persistent challenge in the world of electronics, affecting everything from audio clarity to the reliability of digital signals. Whether you are designing a simple amplifier or a complex microcontroller-based system, understanding how to reduce noise in circuits is essential for achieving optimal performance and reliability. This guide breaks down practical strategies, design considerations, and troubleshooting tips to help engineers, hobbyists, and technicians tackle unwanted interference in their electronic designs.

By the end of this article, you will have a clear understanding of the main sources of noise, proven techniques to minimize its impact, and actionable steps to improve your circuit’s signal integrity. For those interested in PCB design details, you may also want to explore what are test points and their role in diagnostics and debugging.

Understanding the Sources of Electrical Noise

Before implementing solutions, it’s important to identify where interference originates. Electrical noise can be classified into several categories:

- Thermal noise: Generated by the random motion of electrons in resistors and semiconductors.

- Electromagnetic interference (EMI): Caused by external sources such as motors, radio transmitters, or switching power supplies.

- Crosstalk: Occurs when signals in adjacent traces or wires couple into each other, especially in densely packed PCBs.

- Power supply noise: Fluctuations or ripple in the supplied voltage can introduce unwanted signals into sensitive circuitry.

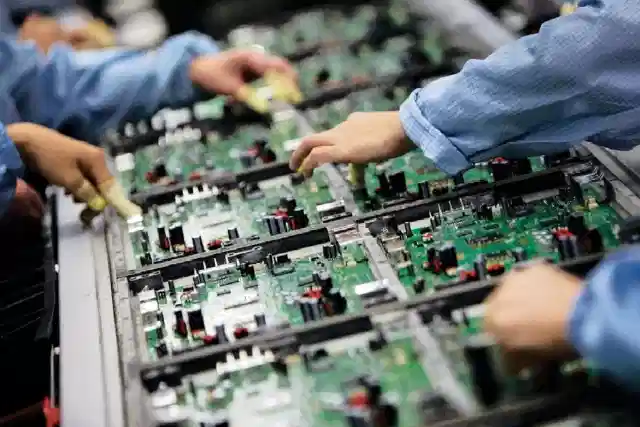

Recognizing these sources is the first step toward effective noise mitigation. For a deeper dive into manufacturing-related aspects, the electronics manufacturing process overview provides additional context on how noise can be introduced during production.

Best Practices for Minimizing Interference

There are several proven methods for reducing unwanted signals in electronic assemblies. The following techniques address both design and layout considerations:

1. Careful PCB Layout and Grounding

A well-designed printed circuit board is fundamental to minimizing interference. Here are some layout tips:

- Use a continuous ground plane to provide a low-impedance return path for signals.

- Keep high-frequency and sensitive analog traces as short as possible.

- Separate analog and digital grounds where feasible, connecting them at a single point.

- Route noisy signals away from sensitive circuitry.

If you’re interested in how vias contribute to signal integrity and noise management, see this resource on how vias are made in PCBs.

2. Shielding and Enclosures

Physical barriers can be highly effective against EMI. Metal enclosures or shields around sensitive components block external fields and prevent emissions from escaping. When designing enclosures:

- Ensure good electrical contact between the shield and ground.

- Minimize openings in the shield; use conductive gaskets if necessary.

- Route cables through filtered connectors to prevent noise ingress.

3. Filtering Techniques for Cleaner Signals

Filters are essential tools for suppressing unwanted frequencies. Common approaches include:

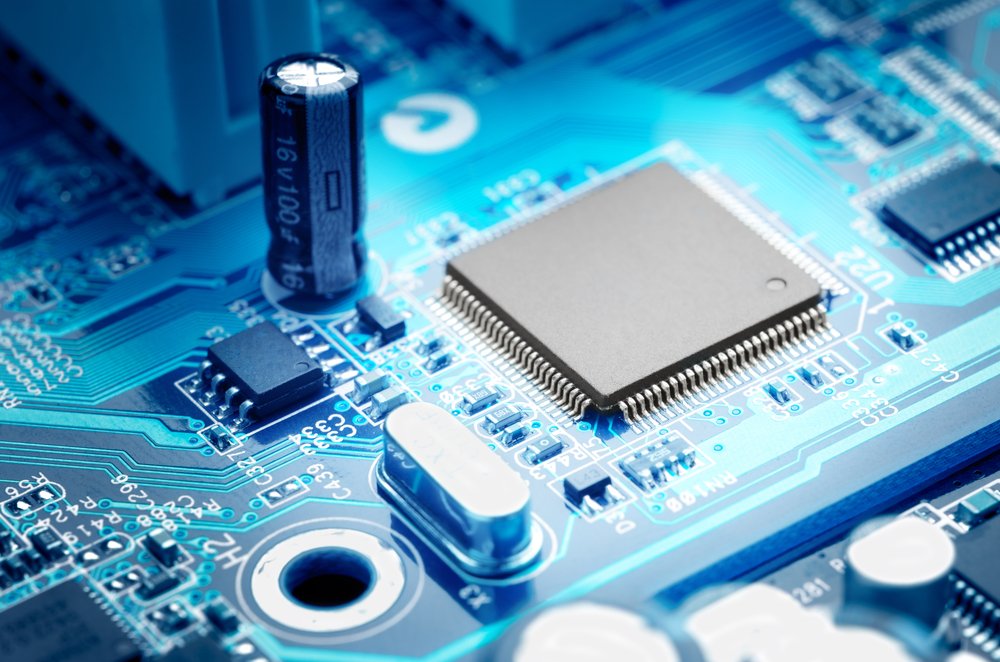

- Decoupling capacitors: Placed close to IC power pins, these capacitors shunt high-frequency noise to ground.

- Ferrite beads: Used on power lines and signal traces to block high-frequency interference.

- Low-pass filters: Remove high-frequency noise from analog signals.

Selecting the right filter values and placement is crucial for optimal performance. For more on inspection and quality control, see electronics inspection methods.

Component Selection and Placement Strategies

Choosing the right components and placing them thoughtfully can make a significant difference in noise levels:

- Opt for low-noise operational amplifiers and voltage regulators in sensitive analog sections.

- Use shielded inductors and transformers when possible.

- Place decoupling capacitors as close as possible to IC power pins.

- Physically separate high-power and low-level signal circuits on the board.

Power Supply Design for Reduced Noise

The quality of your power supply directly impacts the noise floor of your circuit. Here’s how to optimize it:

- Use linear regulators for analog sections where possible, as they generate less switching noise than switching regulators.

- Implement proper filtering at both the input and output of power supplies.

- Isolate noisy digital power rails from sensitive analog supplies.

- Consider star grounding to prevent ground loops.

Testing and Troubleshooting for Quieter Circuits

Even with careful design, some noise may persist. Systematic testing helps identify and resolve these issues:

- Use an oscilloscope to visualize and pinpoint sources of interference.

- Check for ground loops by measuring voltage differences between ground points.

- Temporarily disconnect or shield suspected noise sources to observe changes.

- Ensure all connectors and cables are properly shielded and grounded.

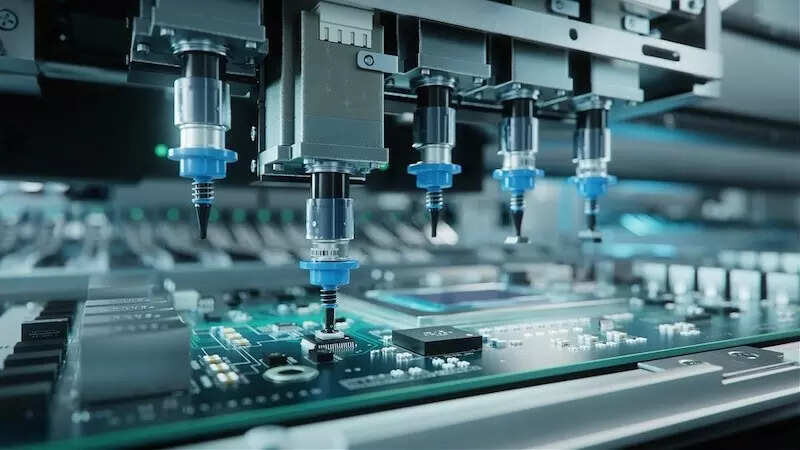

For those interested in assembly steps that can impact noise, the article on how stencil printing works in PCB assembly provides valuable insights.

Advanced Tips for Suppressing Unwanted Signals

For high-performance or mission-critical applications, consider these advanced approaches:

- Implement differential signaling for data lines to reject common-mode noise.

- Use twisted pair cables for long signal runs to minimize EMI pickup.

- Apply conformal coatings to protect against environmental noise sources.

- Employ spread-spectrum clocking to distribute EMI energy over a wider frequency range.

FAQ

What are the most common causes of noise in electronic circuits?

The most frequent sources include thermal agitation in components, electromagnetic interference from nearby devices, crosstalk between traces, and power supply fluctuations. Each of these can introduce unwanted signals that degrade performance.

How can I quickly check if my circuit is affected by noise?

Using an oscilloscope, you can monitor signal lines for unexpected spikes or oscillations. Additionally, listening for hum or static in audio circuits, or observing erratic behavior in digital systems, can indicate the presence of interference.

Are there industry standards for noise reduction in electronics?

Yes, various standards such as CISPR, FCC, and IEC outline acceptable limits for electromagnetic emissions and susceptibility. Adhering to these guidelines during design and testing helps ensure compliance and reliable operation.

Can manufacturing processes introduce noise into circuits?

Absolutely. Poor soldering, inadequate shielding, and improper component placement during assembly can all contribute to increased noise. For more on this, review the electronics manufacturing process overview.

Conclusion

Reducing interference in electronic assemblies is a multifaceted process that involves careful design, component selection, and thorough testing. By applying the strategies outlined here—ranging from PCB layout best practices to advanced filtering and shielding—you can significantly improve the performance and reliability of your projects. Staying informed about manufacturing and inspection methods, such as those described in resources on copper plating process explained, further enhances your ability to deliver robust, low-noise designs.