In today’s fast-paced world of technology, selecting a reliable turnkey electronics manufacturer is crucial for businesses aiming to bring innovative products to market efficiently. The process of how to choose a turnkey electronics manufacturer can seem daunting, but with the right guidance, you can make an informed decision that supports your business goals. Whether you’re an exporter, importer, or a company looking to streamline your production, understanding the key factors in this choice is essential.

Understanding Turnkey Electronics Manufacturing

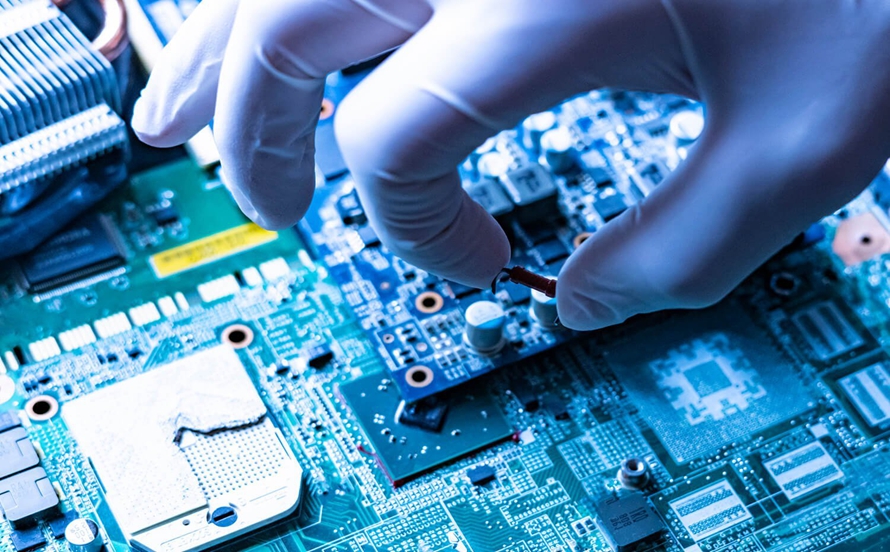

Before diving into the selection process, it’s important to understand what turnkey electronics manufacturing entails. A turnkey provider handles all aspects of the manufacturing process, from design and prototyping to production and assembly. This comprehensive service allows businesses to focus on their core competencies while leaving technical and logistical details to the experts.

Benefits of Turnkey Solutions

Choosing a turnkey solution offers numerous benefits, including reduced time-to-market, cost savings, and enhanced product quality. By partnering with a single provider, companies can streamline communication, reduce errors, and ensure a cohesive production process.

Key Factors in Choosing a Manufacturer

1. Assess the Manufacturer’s Experience

One of the first steps in selecting a turnkey electronics manufacturer is evaluating their experience in the industry. Look for providers with a proven track record in handling projects similar to yours. Experienced manufacturers are more likely to understand the complexities of your product and deliver high-quality results.

2. Evaluate Technical Capabilities

Technical capabilities are a critical consideration. Ensure that the manufacturer has the necessary equipment, technology, and expertise to meet your product’s requirements. Ask about their prototyping, testing, and production processes to gauge their technical proficiency.

3. Consider Quality Assurance Measures

Quality assurance is paramount in electronics manufacturing. Investigate the manufacturer’s quality control processes, certifications, and adherence to industry standards. A strong quality assurance program minimizes the risk of defects and ensures that your product meets customer expectations.

4. Analyze Cost Structure

While cost should not be the sole deciding factor, it’s important to analyze the manufacturer’s pricing structure. Look for transparency in pricing and ensure that there are no hidden fees. Compare costs with the level of service and quality offered to determine the best value for your investment.

Logistical and Communication Considerations

5. Review Supply Chain Management

Effective supply chain management is crucial for timely production and delivery. Evaluate the manufacturer’s ability to source materials, manage inventory, and handle logistics. A well-managed supply chain reduces delays and ensures a smooth production process.

6. Assess Communication and Support

Open and transparent communication is vital in any business relationship. Choose a manufacturer that offers clear communication channels and readily provides updates on project progress. Responsive customer support can address issues promptly and prevent misunderstandings.

Strategic Partnerships and Innovation

7. Evaluate Strategic Partnerships

Consider whether the manufacturer has established strategic partnerships with other companies or technology providers. These partnerships can enhance their capabilities and provide additional resources for your project.

8. Encourage Innovation and Flexibility

In the ever-evolving electronics industry, innovation is key to staying competitive. Choose a manufacturer that values innovation and is willing to adapt to changes in technology and market trends. Flexibility in design and production processes can lead to better product outcomes.

Making the Final Decision

9. Conduct Site Visits

Whenever possible, visit the manufacturer’s facilities to gain firsthand insights into their operations. A site visit allows you to assess their infrastructure, equipment, and overall working environment.

10. Request References and Case Studies

Ask for references and case studies from previous clients to understand their experiences with the manufacturer. Positive feedback and successful case studies indicate reliability and customer satisfaction.

11. Evaluate Contracts and Agreements

Carefully review the terms of any contracts or agreements before finalizing your decision. Ensure that all aspects of the partnership, including timelines, deliverables, and confidentiality, are clearly outlined and agreed upon.

Conclusion

Choosing the right turnkey electronics manufacturer is a critical step in bringing your electronic products to market successfully. By considering factors such as experience, technical capabilities, quality assurance, and communication, you can make an informed decision that aligns with your business objectives. Remember, a strong partnership with a reliable manufacturer can pave the way for innovation and growth in the competitive electronics industry.

FAQ

1. What is a turnkey electronics manufacturer?

A turnkey electronics manufacturer is a company that handles all aspects of the electronics manufacturing process, from design to production and assembly, providing a complete solution for businesses.

2. Why choose a turnkey solution?

Choosing a turnkey solution streamlines the manufacturing process, reduces costs, and ensures high-quality products by centralizing all production activities under one provider.

3. How do I assess a manufacturer’s quality assurance?

Assess a manufacturer’s quality assurance by reviewing their certifications, industry standards adherence, and inspecting their quality control processes.

For more in-depth information, you can visit this article on the benefits and limitations of turnkey electronics manufacturing. Additionally, explore the potential of 5G impact on IoT devices and how open innovation can transform IoT product development.