In the world of electronics, understanding how rugged electronics work is crucial for those in the business of exporting and importing these specialized devices. As technology advances, the need for durable and reliable electronics that can withstand harsh environments increases. This article aims to provide a comprehensive understanding of the intricacies of rugged electronics, focusing on the needs of exporters and importers.

Introduction to Rugged Electronics

Rugged electronics are specifically designed to operate in extreme conditions that would typically damage regular electronic devices. These conditions include extreme temperatures, dust, water exposure, and mechanical shocks. The demand for such electronics is growing in industries like military, aerospace, and industrial manufacturing.

The Importance of Rugged Electronics

For businesses dealing with technology in demanding environments, the importance of rugged electronics cannot be overstated. They ensure operational reliability and longevity, reducing the need for frequent replacements and repairs. This reliability is essential for maintaining business continuity and minimizing downtime.

Key Features of Rugged Electronics

Rugged electronics are characterized by several key features that differentiate them from standard devices. These features include:

- Durability: Built to withstand physical impact and harsh environments.

- Temperature Resistance: Operates efficiently in extreme hot or cold conditions.

- Waterproofing and Dustproofing: Sealed designs prevent ingress of water and dust.

- Shock and Vibration Resistance: Can endure mechanical shocks and vibrations without damage.

How Rugged Electronics Work

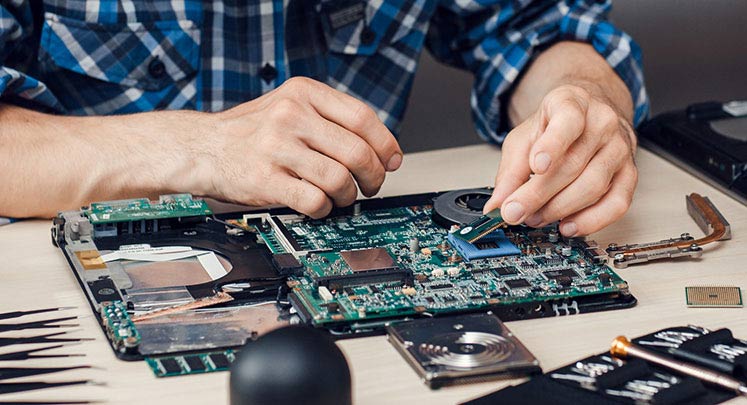

Understanding how rugged electronics work involves looking at their design and manufacturing processes. These devices are engineered with specialized components and materials that enhance their durability and performance.

Design and Materials

The design of rugged electronics focuses on robustness and resilience. They are often encased in heavy-duty materials like magnesium alloy or reinforced plastics. Components are securely mounted to safeguard against vibrations and shocks.

Testing and Standards

Rugged electronics undergo rigorous testing to meet industry standards such as MIL-STD-810 for military applications and IP ratings for water and dust resistance. These standards ensure that the devices can perform reliably under specified conditions.

Applications of Rugged Electronics

Rugged electronics find applications in various sectors where reliability is critical. Some of these sectors include:

- Military and Defense: Used in communication devices, navigation systems, and more.

- Industrial Automation: Employed in machinery control and monitoring systems.

- Aerospace: Integral to avionics and other aircraft systems.

- Outdoor Adventures: Utilized in GPS devices and cameras for extreme sports.

For more insights on EMC testing for rugged electronics in aerospace, visit our related blog.

Challenges in Exporting and Importing Rugged Electronics

Exporters and importers face unique challenges when dealing with rugged electronics. These challenges include navigating compliance regulations, ensuring proper packaging, and managing logistics to prevent damage during transit.

Compliance and Regulations

Adhering to international standards and regulations is critical when exporting or importing rugged electronics. Understanding these regulations helps ensure smooth transactions and avoids legal issues.

Packaging and Logistics

Proper packaging is essential to protect rugged electronics during transport. Exporters must use appropriate materials and methods to ensure devices arrive undamaged. Additionally, choosing reliable logistics partners is crucial for maintaining the integrity of these products.

The Future of Rugged Electronics

The future of rugged electronics looks promising with advancements in technology. Innovations such as IoT integration and enhanced connectivity are expected to drive the growth of this market, offering new opportunities for exporters and importers.

Technological Advancements

Emerging technologies are enhancing the capabilities of rugged electronics, making them more efficient and versatile. These advancements include improved battery life, faster processors, and enhanced connectivity options.

Learn more about how open architecture systems contribute to rugged electronics.

Market Opportunities

The growing demand for rugged electronics presents significant market opportunities for exporters and importers. As industries continue to seek reliable solutions for challenging environments, the need for these specialized devices will only increase.

Conclusion

Understanding how rugged electronics work is essential for those in the business of exporting and importing these devices. With their ability to withstand harsh conditions and deliver reliable performance, rugged electronics are a valuable asset in many industries. By staying informed about technological advancements and market trends, businesses can capitalize on the growing opportunities in this sector.

FAQs

What industries benefit most from rugged electronics?

Industries such as military, aerospace, and industrial automation benefit significantly from rugged electronics due to their need for reliable and durable devices.

How do rugged electronics differ from regular electronics?

Rugged electronics are designed to withstand extreme conditions like temperature fluctuations, water, dust, and mechanical shocks, whereas regular electronics are not built for such environments.

What are the key features to look for in rugged electronics?

Key features include durability, temperature resistance, waterproofing, dustproofing, and shock resistance. These features ensure reliable performance in harsh conditions.

For further reading on rugged electronics design, check out this external resource.