The world of turnkey electronics manufacturing is undergoing a significant transformation, thanks to the emergence of Industry 4.0. This new industrial revolution is reshaping how electronic products are designed, produced, and delivered. For those involved in electronics manufacturing, understanding the impacts of Industry 4.0 is crucial.

Introduction to Industry 4.0

Industry 4.0 represents the fourth wave of industrial advancements, characterized by a fusion of technologies that blur the lines between the physical, digital, and biological spheres. This paradigm shift is driven by the integration of cyber-physical systems, the Internet of Things (IoT), and cloud computing.

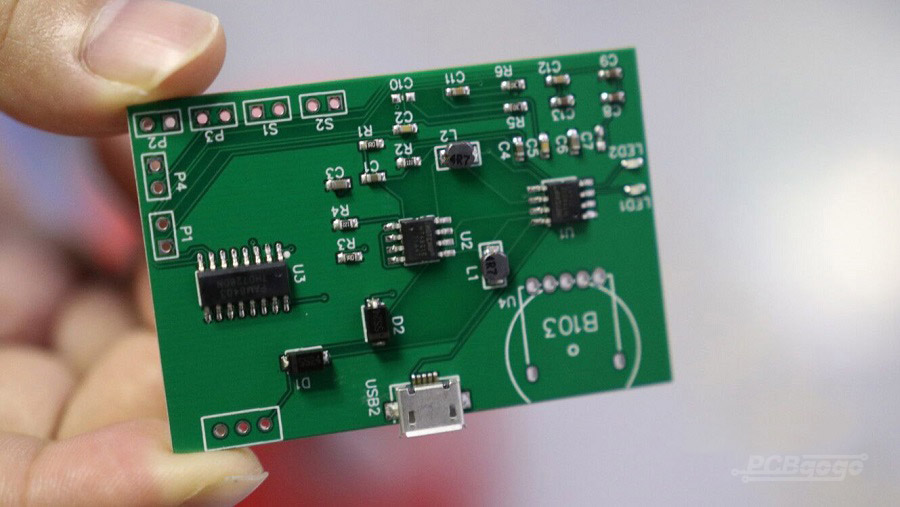

What is Turnkey Electronics Manufacturing?

Turnkey electronics manufacturing refers to a comprehensive approach where a single vendor manages the entire production process from start to finish. This includes everything from design and prototyping to assembly and testing. It allows companies to focus on their core competencies while leaving the manufacturing complexities to experts.

Benefits of Turnkey Solutions

Turnkey solutions offer numerous benefits such as reduced time to market, cost savings, and improved product quality. By relying on a single provider, companies can streamline operations and enhance efficiency.

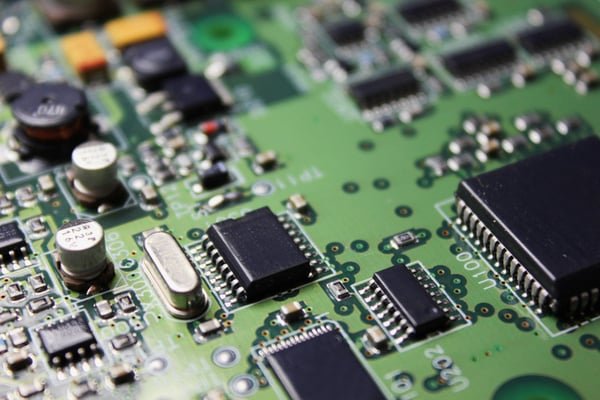

The Role of Advanced Technologies

Incorporating advanced technologies is at the heart of Industry 4.0. Key components like IoT, big data, and artificial intelligence are transforming the landscape of electronics manufacturing.

The Internet of Things (IoT)

IoT enables devices to communicate and share data seamlessly, enhancing automation and enabling predictive maintenance. This connectivity drives efficiency and reduces downtime in manufacturing processes.

Big Data and Analytics

With the influx of data generated from connected devices, big data analytics plays a vital role in decision-making. By leveraging data insights, manufacturers can optimize production processes and improve product quality.

Artificial Intelligence and Machine Learning

AI and machine learning algorithms are redefining the manufacturing landscape by enabling predictive analytics, quality control, and process optimization. These technologies allow for real-time adjustments, ensuring higher precision and efficiency.

Impact of Industry 4.0 on Supply Chain Management

Industry 4.0 has a profound impact on supply chain management in turnkey electronics manufacturing. Smart logistics and real-time tracking enhance transparency and efficiency throughout the supply chain.

Enhanced Supply Chain Visibility

With interconnected systems, manufacturers gain better visibility into their supply chains. This visibility allows for quicker responses to disruptions, leading to more resilient supply chains.

Improved Inventory Management

Advanced technologies enable real-time inventory tracking, reducing the risk of overstocking or stockouts. This optimization leads to cost savings and efficient resource allocation.

Challenges in Adopting Industry 4.0

While the benefits of Industry 4.0 are significant, there are challenges in its adoption. These challenges include high implementation costs, cybersecurity concerns, and the need for skilled workforce.

Cybersecurity Concerns

As manufacturing systems become more interconnected, the risk of cyber threats increases. Ensuring robust cybersecurity measures is essential to protect sensitive data and maintain business operations.

Need for Skilled Workforce

The transition to Industry 4.0 requires a workforce with advanced technical skills. Manufacturers need to invest in training and upskilling their employees to adapt to new technologies.

Future of Turnkey Electronics Manufacturing

The future of turnkey electronics manufacturing is promising with the continuous advancements in Industry 4.0 technologies. These innovations will lead to more efficient, flexible, and sustainable manufacturing processes.

Focus on Sustainability

As environmental concerns grow, manufacturers are focusing on sustainable practices. Industry 4.0 technologies enable energy-efficient production processes and reduce waste.

Increased Customization

With advanced technologies, manufacturers can offer increased customization options to meet specific customer needs. This flexibility enhances customer satisfaction and brand loyalty.

Conclusion

Industry 4.0 is revolutionizing turnkey electronics manufacturing by integrating cutting-edge technologies that enhance efficiency, reduce costs, and improve product quality. While there are challenges in adoption, the benefits far outweigh the hurdles, paving the way for a future of innovation and growth in the electronics manufacturing sector. For more detailed insights, consider visiting Turnkey PCB Assembly.

FAQs

What is Industry 4.0?

Industry 4.0 is the fourth industrial revolution characterized by the integration of digital technologies into manufacturing processes, leading to smarter and more efficient production systems.

How does Industry 4.0 impact supply chain management?

Industry 4.0 enhances supply chain management by improving visibility, enabling real-time tracking, and optimizing inventory management, leading to more efficient and resilient supply chains.

What challenges do manufacturers face in adopting Industry 4.0?

Manufacturers face challenges such as high implementation costs, cybersecurity risks, and the need for skilled workforce in the adoption of Industry 4.0 technologies.