The world of electronics relies on a vast array of components, from tiny resistors and capacitors to complex integrated circuits. Understanding how electronics components are made offers valuable insight into the technology that powers everything from smartphones to industrial machinery. This guide explores the materials, processes, and technologies behind the creation of these essential building blocks, providing a clear look at the journey from raw materials to finished parts.

For those interested in the broader context of electronics production, you may also want to explore the electronics manufacturing steps involved in assembling complete devices.

Key Materials Used in Electronic Component Production

Every electronic part starts with carefully selected materials. The choice of material impacts performance, durability, and cost. Here are some of the most common materials used:

- Silicon: The foundation of most semiconductors and integrated circuits due to its excellent electrical properties.

- Copper: Widely used for wiring and connections because of its high conductivity.

- Ceramics: Essential for capacitors and insulators, providing stability and resistance to heat.

- Metals and Alloys: Used in resistors, connectors, and leads for their specific resistive or conductive properties.

- Plastics and Polymers: Often form casings, insulation, and flexible circuit boards.

The selection and purity of these materials are critical for ensuring the reliability and efficiency of the final products.

Manufacturing Processes for Passive Components

Passive components like resistors, capacitors, and inductors are fundamental to electronic circuits. The processes for making these parts are highly automated and precise.

Resistor Fabrication

To create resistors, manufacturers start with a ceramic or metal oxide substrate. A resistive material, such as carbon film or metal film, is deposited onto the substrate. The resistance value is controlled by adjusting the thickness and length of the film. The component is then encased in a protective coating and fitted with metal leads for connection.

Capacitor Production

Capacitors are made by layering conductive plates (often aluminum or tantalum) with insulating materials (dielectrics) like ceramic or plastic film. These layers are stacked, wound, or rolled, depending on the type. The assembly is then sealed to protect against moisture and contamination.

Inductor Assembly

Inductors are produced by winding copper wire around a magnetic core, such as ferrite or iron. The number of turns and the core material determine the inductance value. The finished coil is coated or enclosed to maintain its shape and shield it from external interference.

Semiconductor and Integrated Circuit Manufacturing

The process of making semiconductors and integrated circuits is among the most advanced in modern manufacturing. These components are at the heart of digital technology, enabling computation, memory, and signal processing.

Silicon Wafer Preparation

The journey begins with the creation of ultra-pure silicon wafers. Silicon is melted and formed into large cylindrical ingots, which are then sliced into thin wafers. These wafers serve as the base for building microscopic circuits.

Photolithography and Etching

Photolithography is used to transfer intricate circuit patterns onto the wafer. A light-sensitive material called photoresist is applied, and ultraviolet light projects the desired pattern. Chemical etching removes unwanted material, leaving behind the circuit design.

Doping and Layering

Doping introduces impurities into specific areas of the silicon to alter its electrical properties. Multiple layers of materials are deposited and patterned to create transistors, diodes, and other elements. This process is repeated many times to build complex integrated circuits.

Testing and Packaging

After fabrication, each chip is tested for functionality. Good chips are cut from the wafer, mounted onto a substrate, and encapsulated in a protective package. Leads or solder balls are added for electrical connection to circuit boards.

Assembly and Quality Control in Electronics Manufacturing

Once individual components are produced, they are assembled onto printed circuit boards (PCBs) to form functional devices. This stage involves both automated and manual processes to ensure accuracy and reliability.

Surface-mount technology (SMT) and through-hole mounting are two common methods for placing components on PCBs. Automated pick-and-place machines position parts with high precision, followed by soldering processes like reflow or wave soldering. For a deeper dive into these steps, see the article on how reflow soldering works.

Quality control is crucial at every stage. Automated optical inspection, electrical testing, and X-ray analysis help detect defects and ensure that each component and assembly meets strict standards.

Recent Advances in Component Production

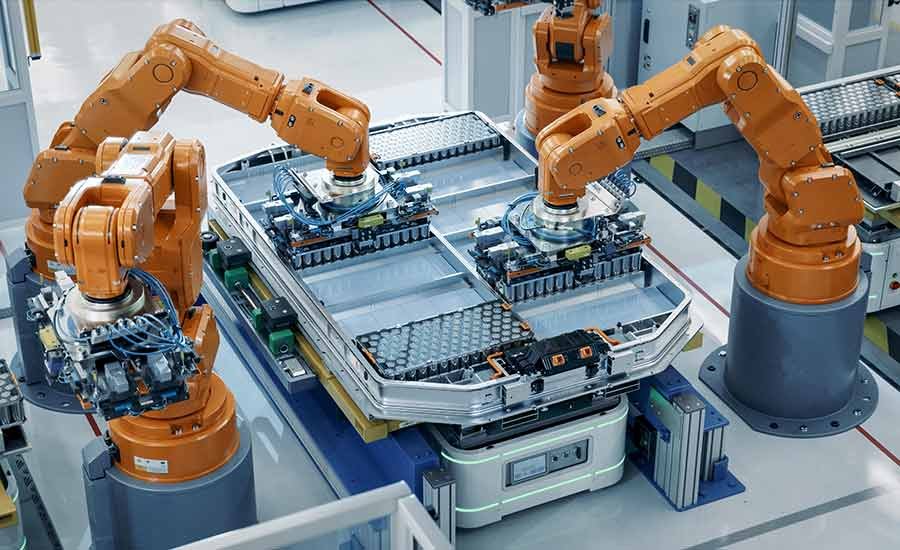

The field of electronics manufacturing is constantly evolving. Advances in automation, robotics, and materials science have led to smaller, more powerful, and more reliable components. For example, the use of robotic assembly lines has dramatically increased production speed and consistency, while innovations in nanotechnology enable the creation of components with features measured in billionths of a meter.

Environmental considerations are also shaping the industry. Lead-free solder, recyclable materials, and energy-efficient processes are becoming standard as manufacturers strive to reduce their ecological footprint.

For a comprehensive overview of the entire process, from component fabrication to final assembly, you can refer to the complete process of electronic manufacturing services.

Frequently Asked Questions

What are the main steps in producing electronic components?

The process typically involves selecting raw materials, fabricating the component (such as depositing films or winding coils), assembling and packaging, and finally, rigorous testing to ensure quality and performance.

How are integrated circuits different from discrete components?

Integrated circuits (ICs) are made by building multiple electronic functions onto a single silicon chip using photolithography and layering techniques. Discrete components, like resistors or capacitors, are individual parts with a single function.

Why is quality control so important in electronics manufacturing?

High reliability is essential in electronics, as even minor defects can cause device failure. Quality control ensures that each component meets strict standards for performance, safety, and durability.

Conclusion

The creation of electronic components is a complex, multi-stage process that combines advanced materials, precision engineering, and strict quality standards. From the selection of raw materials to the final assembly on circuit boards, each step is designed to ensure that the resulting parts are reliable and efficient. As technology continues to advance, the methods used to produce these components will only become more sophisticated, supporting the ever-growing demand for smarter, smaller, and more powerful devices.