The journey from a concept to a fully functional electronic device involves a series of precise and carefully controlled steps. Understanding how electronics are manufactured helps shed light on the complexity behind everyday gadgets, from smartphones to industrial equipment. This guide breaks down each stage of the process, highlighting the key techniques, technologies, and quality checks that ensure reliable and high-performing products.

For those interested in the broader context of hardware development, exploring the hardware engineering project workflow provides valuable insight into how design, prototyping, and manufacturing are interconnected.

Overview of the Electronics Production Workflow

Manufacturing electronic products is a multi-stage process that transforms raw materials and components into finished devices. The workflow typically includes design, prototyping, sourcing, assembly, testing, and packaging. Each phase requires specialized knowledge and equipment to ensure the final product meets performance and safety standards.

Design and Prototyping: The Foundation of Manufacturing

Every electronic device starts with a detailed design phase. Engineers use computer-aided design (CAD) tools to create schematics and layouts for printed circuit boards (PCBs). These designs specify the arrangement of components, electrical connections, and mechanical features.

Once the design is complete, a prototype is built. Prototyping allows engineers to test the concept, identify issues, and make improvements before mass production. Early feedback during this stage is crucial, as it can prevent costly errors down the line. For more on why this matters, see the importance of early prototyping feedback.

Component Sourcing and Quality Control

After finalizing the design, manufacturers source electronic components such as resistors, capacitors, integrated circuits, and connectors. Reliable sourcing is essential to avoid counterfeit or substandard parts, which can compromise device performance.

Quality control measures are implemented at this stage. Components are inspected for compliance with specifications and tested for electrical properties. Advanced techniques, including automated optical inspection (AOI) and X-ray analysis, help detect defects before assembly. For a deeper look at component testing, refer to electronic component testing standards and advanced techniques.

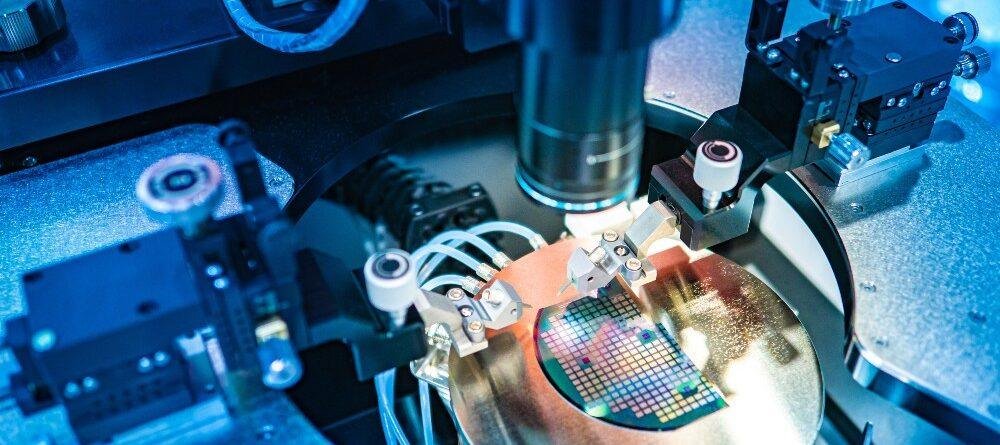

PCB Fabrication: Building the Circuit Board

The PCB serves as the backbone of most electronic devices. Its fabrication involves several key steps:

- Substrate Preparation: The process begins with a fiberglass or composite base, coated with a thin layer of copper.

- Imaging and Etching: The circuit pattern is transferred onto the copper using a photosensitive mask. Unwanted copper is then etched away, leaving only the desired traces.

- Drilling: Precision drills create holes for component leads and vias, which connect different layers of the board.

- Plating and Solder Mask: Holes are plated with conductive material, and a protective solder mask is applied to prevent short circuits.

- Silkscreen Printing: Labels and markings are printed to aid assembly and troubleshooting.

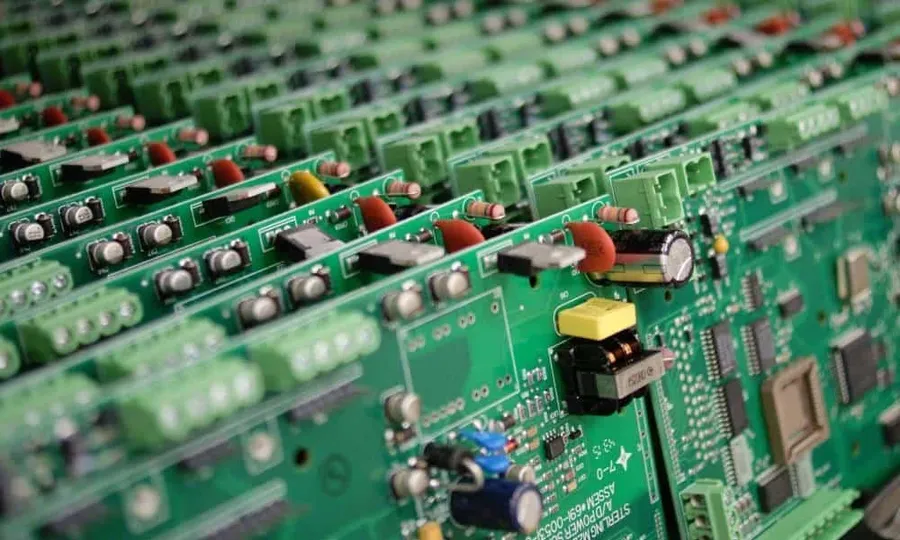

Assembly: Placing and Soldering Components

With the PCB ready, the next step is to mount electronic components onto the board. This is typically done using two main methods:

- Surface Mount Technology (SMT): Components are placed directly onto the surface of the PCB and soldered using reflow ovens. SMT allows for high-density, automated assembly.

- Through-Hole Technology: Components with leads are inserted into pre-drilled holes and soldered from the opposite side. This method is used for parts that require mechanical strength or high power handling.

Automated machines, such as pick-and-place robots, ensure precise component placement. Solder paste is applied to pads, and heat is used to create strong electrical connections.

Inspection and Testing: Ensuring Quality and Reliability

Rigorous inspection and testing are vital to guarantee that electronic products function as intended. Common quality assurance steps include:

- Automated Optical Inspection (AOI): Cameras scan the assembled boards for missing, misplaced, or defective components.

- In-Circuit Testing (ICT): Electrical probes check for shorts, opens, and correct values at various points on the board.

- Functional Testing: The device is powered on and operated to verify that all features work as specified.

- Environmental Stress Testing: Some products undergo temperature, humidity, or vibration tests to ensure durability in real-world conditions.

Any issues detected during testing are addressed through rework or repair. This step is crucial for maintaining high standards and minimizing returns or failures in the field.

Final Assembly, Packaging, and Shipping

Once the electronics pass all tests, they move to final assembly. This may involve enclosing the PCB in a protective case, adding connectors, displays, or other mechanical parts. The completed units are then packaged with accessories, manuals, and labels.

Packaging is designed to protect the product during transit and to comply with regulatory requirements. After packaging, products are shipped to distributors, retailers, or directly to customers.

Continuous Improvement and Industry Trends

The field of electronics manufacturing is constantly evolving. Advances in automation, miniaturization, and materials science drive improvements in efficiency, cost, and product capabilities. Manufacturers regularly review their processes to adopt new technologies and meet changing market demands.

Staying updated with hardware design trends and innovations helps companies remain competitive and deliver better products to consumers.

Common Challenges in the Manufacturing Process

Producing high-quality electronics involves overcoming several challenges:

- Supply Chain Disruptions: Delays or shortages of critical components can halt production lines.

- Quality Assurance: Detecting subtle defects requires advanced inspection systems and skilled technicians.

- Design Complexity: As devices become more sophisticated, ensuring manufacturability and reliability becomes harder.

- Regulatory Compliance: Products must meet safety, environmental, and performance standards in different markets.

Addressing these issues requires close collaboration between design, engineering, and manufacturing teams, as well as strong relationships with suppliers.

Frequently Asked Questions

What is the most important step in electronics manufacturing?

Every stage is critical, but thorough design and prototyping lay the groundwork for a successful product. Early detection of design flaws reduces costly revisions later in the process.

How do manufacturers ensure the quality of electronic components?

Quality is maintained through rigorous component testing, supplier audits, and advanced inspection methods such as AOI and X-ray analysis. For more information, see this guide on electronic component testing standards and advanced techniques.

What role does automation play in the production of electronics?

Automation increases precision, speed, and consistency in processes like component placement, soldering, and inspection. It also helps reduce human error and lower manufacturing costs.