The integration of artificial intelligence (AI) in various industries has revolutionized processes and operations. One such field that has significantly benefited from AI is turnkey electronics production. In this article, we delve into how AI is used in turnkey electronics production and its impact on the industry.

The Basics of Turnkey Electronics Production

Before exploring the role of AI, it’s essential to understand what turnkey electronics production entails. This process involves a service provider managing the entire production cycle, from design to delivery. It includes everything from sourcing materials to assembling and testing the final product.

The Role of AI in Streamlining Production

AI plays a crucial role in streamlining turnkey electronics production. By automating repetitive tasks, AI allows human workers to focus on more complex responsibilities. This not only boosts efficiency but also enhances productivity.

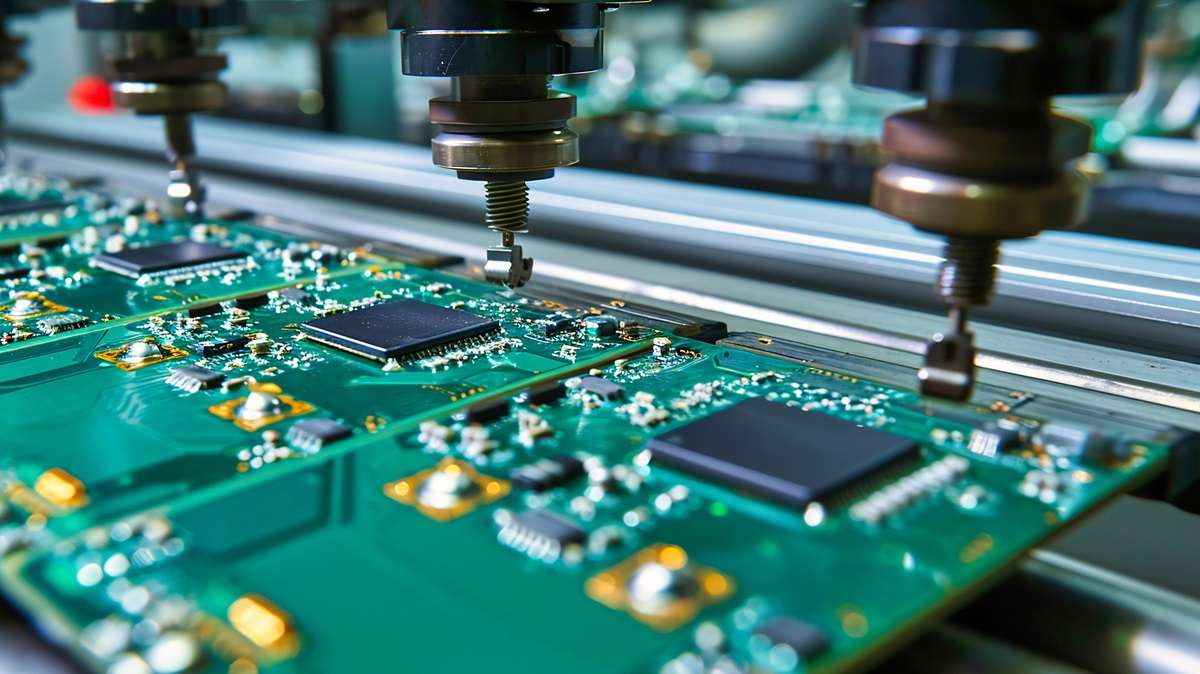

Automation of Assembly Processes

AI-driven robots and machines are now being used to automate assembly lines. These machines can perform tasks with precision and speed, reducing errors and increasing output. For more insights on automation, check the automated inspection process.

Predictive Maintenance

AI algorithms analyze data collected from machines to predict when maintenance is needed. This prevents unexpected breakdowns, saving time and money. Companies can plan maintenance schedules without disrupting production.

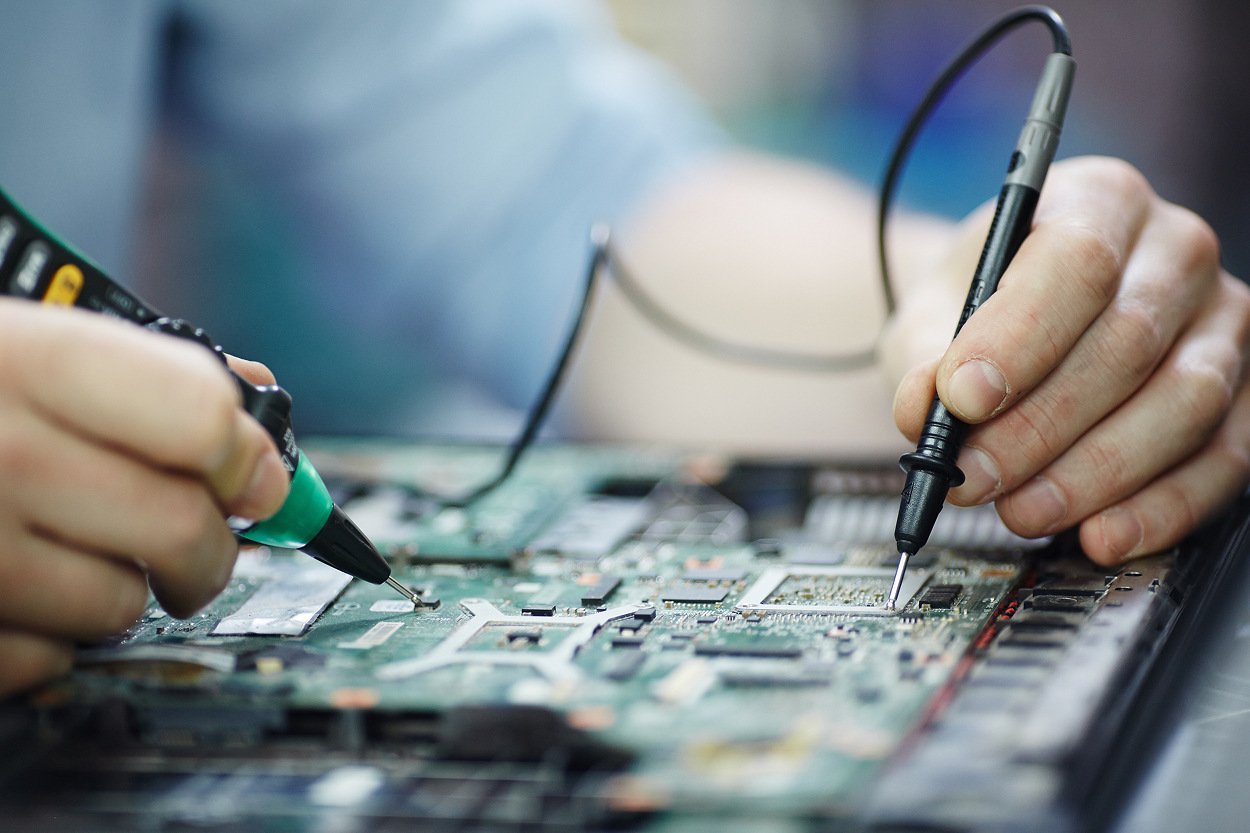

Enhancing Quality Control

Quality control is a vital aspect of turnkey electronics production. AI technology enhances this process by identifying defects that might go unnoticed by human eyes. Advanced image recognition systems powered by AI can detect flaws with high accuracy.

Real-Time Monitoring

AI systems provide real-time monitoring of production processes. This enables quick adjustments and ensures that quality standards are consistently met. PCB assembly improvements are a testament to this capability.

Optimizing Supply Chain Management

AI optimizes supply chain management by predicting demand and managing inventory efficiently. This ensures that the right materials are available at the right time, preventing delays and reducing costs.

Inventory Management

AI tools analyze past data to forecast future demand, enabling better inventory management. This reduces the risk of overstocking or stockouts, ensuring a smooth production process.

AI-Driven Design and Prototyping

AI assists in the design and prototyping stages by generating innovative designs and testing them virtually. This accelerates the development process and reduces the time-to-market for new products.

Virtual Testing and Simulation

Before physical prototypes are built, AI-driven simulations test designs under various conditions. This identifies potential issues early, saving time and resources in the long run.

Reduced Overhead Costs

By automating various production processes, AI helps reduce overhead costs. This makes turnkey electronics production more cost-effective for companies. Learn how turnkey solutions reduce costs effectively.

Ensuring Consistent Product Quality

Consistency in product quality is critical in electronics manufacturing. AI systems ensure that every product meets the required standards, minimizing defects and recalls. Explore more on consistent quality assurance in turnkey production.

AI in Automotive Electronics

The automotive industry relies heavily on electronics. AI in turnkey electronics production ensures that automotive electronics are produced efficiently and meet industry standards. Dive deeper into automotive electronics production.

Challenges and Considerations

While AI offers numerous benefits, there are challenges to consider. These include the initial investment in AI technology and the need for skilled personnel to manage AI systems.

Data Security Concerns

With AI systems handling vast amounts of data, ensuring data security is paramount. Companies must implement robust security measures to protect sensitive information.

Adapting to Technological Changes

The rapid pace of technological advancements means companies must continuously adapt to stay competitive. This involves ongoing training and investment in the latest AI technologies.

The Future of AI in Turnkey Electronics Production

As AI technology continues to evolve, its role in turnkey electronics production will only grow. Companies that embrace AI will be better positioned to innovate and thrive in the competitive electronics market.

Emerging Trends

Future trends include the integration of AI with other technologies such as IoT and blockchain to further enhance production processes and supply chain management.

Long-Term Benefits

The long-term benefits of AI in turnkey electronics production include increased efficiency, reduced costs, and improved product quality. For more insights on choosing the right manufacturing approach, visit Aimtron.

Conclusion

In conclusion, AI is transforming turnkey electronics production by enhancing efficiency, quality, and cost-effectiveness. As technology continues to advance, its impact will become even more profound, offering new opportunities for innovation in the electronics industry.

FAQs

What is turnkey electronics production?

Turnkey electronics production is a process where a single service provider manages the entire production cycle, from design to delivery, including sourcing materials and assembly.

How does AI enhance quality control in electronics production?

AI enhances quality control by using advanced image recognition systems to detect defects with high accuracy, ensuring that quality standards are consistently met.

What are the future trends in AI for electronics production?

Future trends include the integration of AI with IoT and blockchain to enhance production processes and supply chain management, leading to increased efficiency and innovation.