Understanding the hidden costs in turnkey manufacturing is essential for exporters and importers looking to optimize their supply chains. At first glance, turnkey manufacturing offers a comprehensive solution, bundling all aspects of production into a single package. However, beneath the surface, there can be various unforeseen expenses that could impact your bottom line.

What is Turnkey Manufacturing?

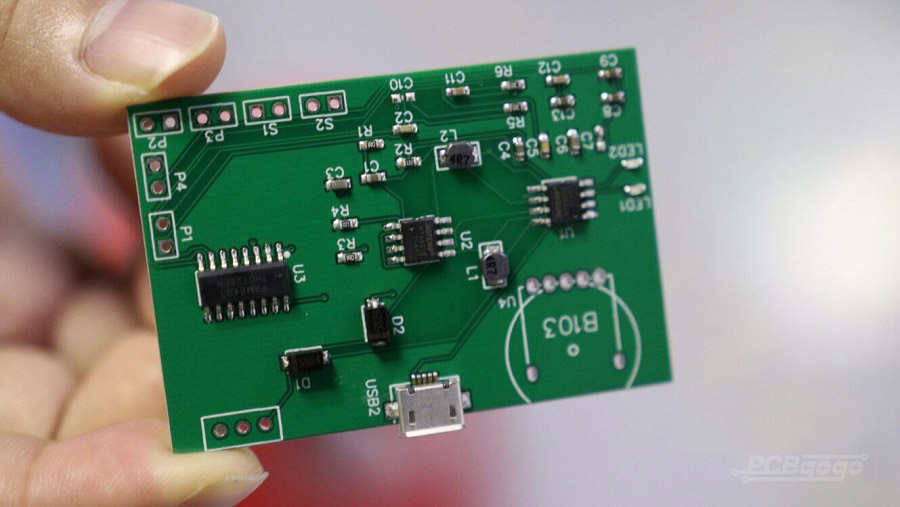

Turnkey manufacturing refers to a process where a manufacturer handles every step of production, from design and sourcing to assembly and delivery. This approach is designed to simplify the production process, making it attractive for businesses looking to reduce complexity and focus on their core activities.

The Appeal of Turnkey Solutions

For many businesses, the appeal of turnkey solutions lies in their promise of convenience and efficiency. By outsourcing the entire production process, companies can save time and resources that would otherwise be spent on managing multiple vendors and processes. However, these benefits can sometimes mask underlying costs.

Understanding Hidden Costs

While the upfront costs of turnkey manufacturing might seem straightforward, there are several hidden costs that can arise. These can include unexpected fees, quality control issues, and communication challenges. It is crucial for businesses to identify and manage these costs to avoid any negative impact on their profitability.

Common Hidden Costs in Turnkey Manufacturing

1. Quality Control Issues

One of the primary hidden costs in turnkey manufacturing is related to quality control. When a single entity manages the entire process, there might be lapses in quality assurance due to lack of oversight. This can lead to defective products, resulting in costly recalls or rework.

2. Communication and Coordination

Effective communication is vital in turnkey manufacturing. Miscommunication can lead to delays or errors in production. These can incur additional costs as companies work to rectify issues that could have been avoided with clearer communication channels.

3. Additional Fees

Turnkey providers may charge additional fees for services that were not initially included in the contract. These could include expedited shipping, customizations, or changes in production volumes. It’s important to scrutinize contracts carefully to understand what is included and what may be charged extra.

Strategies to Mitigate Hidden Costs

1. Conduct Thorough Vendor Research

Before engaging with a turnkey manufacturer, conduct comprehensive research on potential vendors. Check their track record, client reviews, and industry reputation. This can help ensure that you choose a reliable partner who delivers quality service without hidden fees.

2. Clear Contractual Agreements

Ensure that all agreements are clearly documented in the contract. Specify all services included in the turnkey package and clarify any additional costs that might arise. This can prevent unexpected expenses and ensure that both parties have a mutual understanding of the agreement.

3. Regular Quality Audits

Implement regular quality audits to monitor the production process. This can help identify potential issues early, allowing for corrective measures before they escalate into costly problems.

4. Transparent Communication

Establish transparent and effective communication channels with your turnkey provider. Regular updates and feedback can help address any issues promptly and maintain a smooth production process.

Conclusion

While turnkey manufacturing offers significant advantages, it is crucial for exporters and importers to be aware of the potential hidden costs. By understanding these costs and implementing strategies to mitigate them, businesses can maximize the benefits of turnkey solutions while minimizing financial risks.

FAQs

What are turnkey solutions?

Turnkey solutions involve a provider handling the entire production process, delivering a ready-to-use product.

How can I identify hidden costs?

Thoroughly review contracts, communicate with your provider, and conduct quality audits to identify potential hidden costs.

Why is communication important in turnkey manufacturing?

Effective communication helps prevent misunderstandings and errors, reducing the risk of costly production issues.

For more insights on turnkey electronics manufacturing, check out this comprehensive guide.

For more information about how turnkey manufacturing impacts quality, visit our Turnkey Quality blog post.