Hardware layout optimization is a critical aspect of modern electronics design. It involves arranging components on a printed circuit board (PCB) to maximize performance, minimize size, and improve reliability. In this article, we will delve into some of the most effective strategies for optimizing hardware layouts.

Before we delve deeper, it’s worth mentioning the importance of proper hardware design documentation standards. Having a clear and comprehensive documentation process can significantly streamline the optimization process.

Component Placement Strategies

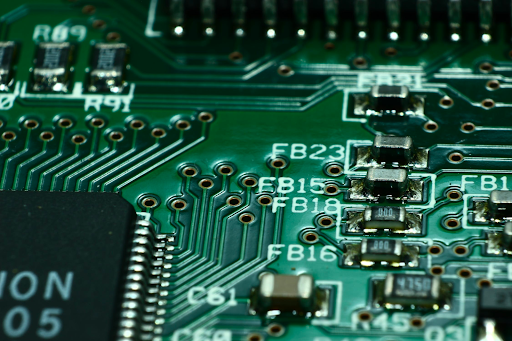

The placement of components on a PCB plays a significant role in the overall performance of the hardware. Proper component placement can reduce signal interference, improve heat dissipation, and enhance the overall reliability of the hardware.

Optimizing Signal Paths

Another important aspect of hardware layout optimization involves optimizing signal paths. This can be achieved by minimizing the length of signal paths and avoiding crossing signal paths wherever possible.

Power Distribution Considerations

Power distribution is another critical consideration in hardware layout optimization. It’s essential to ensure that power is distributed evenly across the PCB to prevent overheating and ensure reliable operation.

Thermal Management

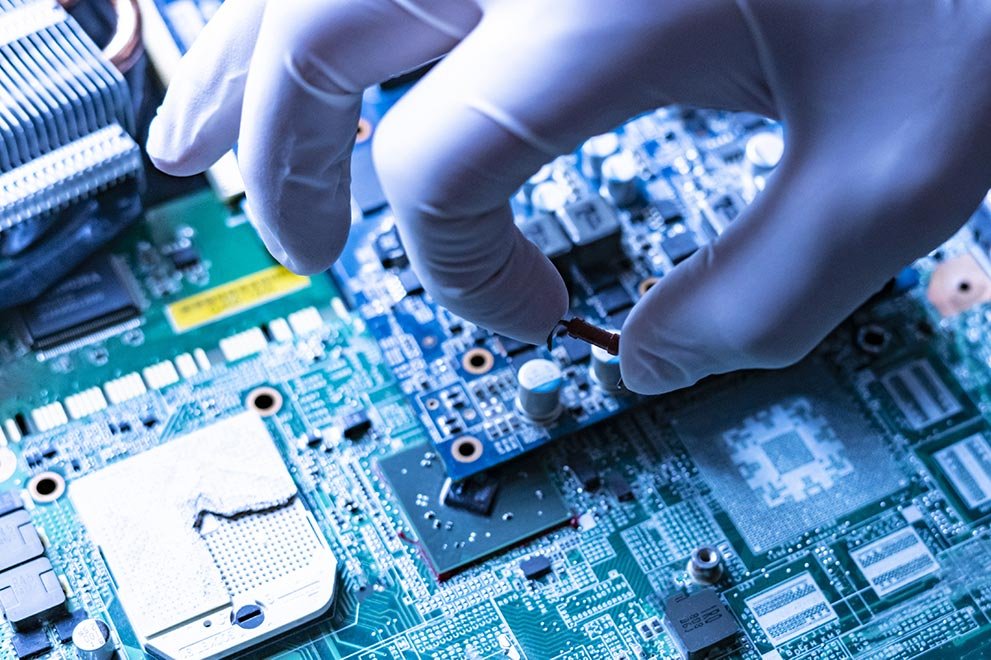

Thermal management is another crucial aspect of hardware layout optimization. Proper thermal management can prevent overheating, extend the lifespan of components, and improve the overall reliability of the hardware.

For more in-depth information on rapid prototyping and hardware layout optimization, check out this comprehensive guide on rapid prototyping.

In conclusion, hardware layout optimization is a complex but essential process that can significantly enhance the performance and reliability of electronic devices. By following the techniques outlined in this article, designers and engineers can create more efficient and reliable hardware layouts.