The landscape of turnkey manufacturing is evolving at an unprecedented pace. As we look to the future, it’s crucial to understand how these changes will impact exporters and importers globally. The future trends in turnkey manufacturing promise exciting advancements that will revolutionize how products are designed, manufactured, and delivered.

In this article, we will explore these trends and what they mean for the industry. From technological innovations to shifts in global supply chains, businesses need to stay informed to remain competitive.

The Rise of Automation in Turnkey Manufacturing

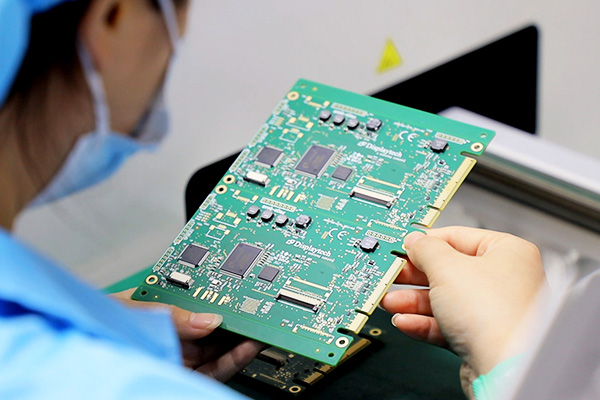

Automation is becoming a cornerstone in the turnkey manufacturing process. With advanced robotics and AI, manufacturers can achieve higher efficiency and precision. This trend is particularly beneficial for exporters and importers who rely on consistent product quality and timely deliveries.

Automated inspection is one aspect where technology is making significant strides, ensuring products meet stringent quality standards.

Impacts of Automation

Automation reduces human error, lowers production costs, and increases output. For businesses involved in international trade, this means more competitive pricing and faster market entry.

Adoption of Smart Manufacturing Technologies

Smart manufacturing integrates IoT and data analytics into the production process. This trend is set to transform turnkey manufacturing by providing real-time insights into production lines.

These insights help manufacturers optimize processes, predict maintenance needs, and reduce downtime. For exporters and importers, this translates to improved reliability and efficiency in supply chain operations.

The Role of IoT

The Internet of Things (IoT) connects machines and systems, enabling seamless communication. This connectivity is crucial for achieving the flexibility and responsiveness needed in today’s dynamic markets.

Sustainability in Turnkey Manufacturing

As environmental concerns grow, sustainability is becoming a priority in turnkey manufacturing. Companies are adopting eco-friendly practices to reduce their carbon footprint and meet regulatory requirements.

This shift towards sustainability is not just about compliance; it’s also a strategic move to appeal to environmentally conscious consumers. For businesses engaged in global trade, demonstrating a commitment to sustainability can enhance brand reputation and customer loyalty.

Green Manufacturing Practices

Green manufacturing involves using renewable energy sources, minimizing waste, and recycling materials. These practices not only protect the environment but also offer cost savings.

Customization and Personalization in Manufacturing

Consumers are increasingly demanding products tailored to their specific needs. This trend is driving turnkey manufacturers to offer more customization options.

By leveraging technologies like 3D printing and flexible manufacturing systems, companies can produce customized products quickly and cost-effectively. This capability is a significant advantage for exporters and importers looking to cater to diverse markets.

Benefits of Customization

Customization enhances customer satisfaction and builds brand loyalty. It also allows companies to differentiate their offerings in competitive markets.

Resilience in Supply Chains

The COVID-19 pandemic highlighted the vulnerabilities in global supply chains. As a result, businesses are focusing on building resilience in their supply chain operations.

This includes diversifying suppliers, investing in local production, and using digital tools to improve supply chain visibility. By strengthening their supply chains, companies can better withstand disruptions and continue to meet customer demands.

Strategies for Building Resilience

Effective strategies involve scenario planning, risk assessment, and developing contingency plans. These measures help companies mitigate risks and ensure business continuity.

Conclusion

The future trends in turnkey manufacturing are set to redefine the industry. By embracing automation, smart technologies, sustainability, and customization, businesses can position themselves for success in a rapidly changing world.

For exporters and importers, staying informed about these trends and adapting to new technologies will be key to maintaining a competitive edge. As we look to the future, the opportunities for innovation and growth in turnkey manufacturing are limitless.

FAQ

What is turnkey manufacturing?

Turnkey manufacturing refers to a comprehensive production process where a single provider manages all aspects of manufacturing, from design to delivery.

Why is automation important in manufacturing?

Automation improves efficiency, reduces costs, and enhances product quality, making it crucial for staying competitive in the global market.

How can businesses benefit from smart manufacturing?

Smart manufacturing offers real-time data insights, optimizing production processes and improving overall operational efficiency.