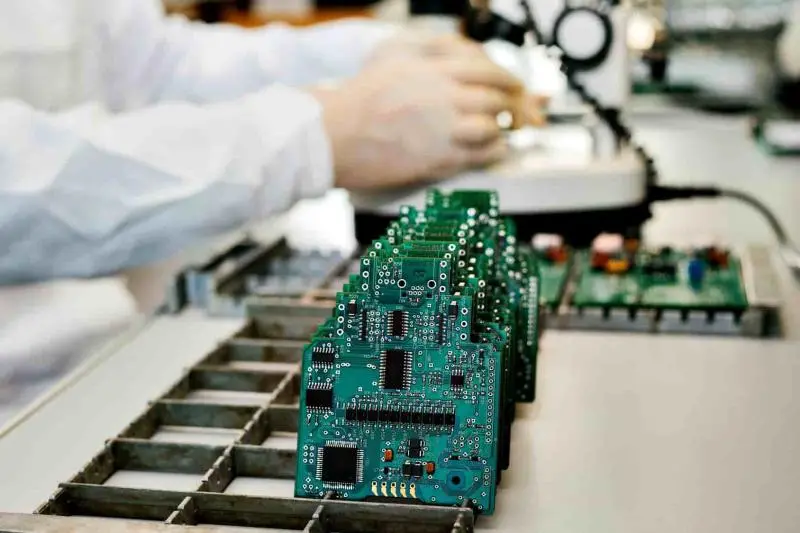

In the world of electronics, ensuring that products perform their intended functions is crucial for success. This is where functional testing of electronics in turnkey process comes into play. For both exporters and importers, understanding this process can be a game-changer. The goal of functional testing is to verify that each component of an electronic device works as expected, which ultimately determines the quality of the final product.

The functional testing of electronics in turnkey process is a critical step in the manufacturing and production cycle. It is essential to catch any potential issues before they reach the consumer, ensuring reliability and customer satisfaction. Let’s dive deeper into what this process entails and why it is so important for exporters and importers.

Understanding Turnkey Processes in Electronics

The term ‘turnkey’ refers to a complete product or service that is ready for immediate use. In electronics, a turnkey process involves everything from initial design to final production, including all necessary components and testing phases. This approach is particularly appealing to exporters and importers because it simplifies the supply chain and reduces the complexity of managing multiple vendors.

Benefits of Turnkey Processes

One of the primary advantages of a turnkey process is the ability to streamline the production cycle. By working with a single provider who handles everything from start to finish, companies can save time, reduce costs, and minimize risks associated with product development. Additionally, the consistency of using a single vendor often leads to higher quality products.

For more insights on the advantages of turnkey processes, check out this article on Turnkey Procurement.

The Role of Functional Testing

Functional testing is a critical component of the turnkey process. This phase involves evaluating each electronic component to ensure it performs its intended function. The testing can range from basic checks to advanced diagnostics, depending on the complexity of the product.

Types of Functional Testing

There are various types of functional testing used in the electronics industry, including:

- Unit Testing: Testing individual components or modules for functionality.

- Integration Testing: Ensuring that combined components work together seamlessly.

- System Testing: Evaluating the entire system to verify it meets specified requirements.

Importance for Exporters and Importers

For exporters and importers, the significance of functional testing cannot be overstated. It is a key factor in ensuring that exported products meet international standards and regulations. Without thorough testing, there is a risk of product recalls, which can be costly and damaging to a company’s reputation.

In addition to compliance, functional testing helps build trust with customers. When a product consistently performs as expected, it strengthens the brand’s reputation and can lead to repeat business.

Case Study: Successful Implementation

Consider a company that specializes in producing electronic components for smartphones. By implementing a thorough turnkey process with rigorous functional testing, they were able to reduce defects by 30% and increase customer satisfaction. This case study highlights the tangible benefits of investing in comprehensive testing procedures.

Challenges in Functional Testing

Despite its importance, functional testing can present challenges. These include high costs, time constraints, and the need for specialized equipment. However, these challenges can often be mitigated by partnering with experienced providers who offer turnkey solutions.

Overcoming Testing Challenges

To overcome these challenges, it’s essential to work with a reliable partner who has a proven track record in functional testing. By leveraging their expertise and resources, companies can ensure their products meet the highest quality standards.

Future Trends in Functional Testing

As technology continues to evolve, so too will the methods used in functional testing. Future trends include the integration of artificial intelligence and machine learning to improve testing accuracy and efficiency. These advancements promise to make functional testing even more effective in the years to come.

Conclusion

In conclusion, the functional testing of electronics in turnkey process is an essential practice for exporters and importers. It ensures product reliability, compliance with international standards, and customer satisfaction. By understanding and implementing comprehensive testing procedures, companies can reduce risks, enhance their reputation, and ultimately, achieve greater success in the global market.

For more information on how turnkey processes can benefit your business, visit this external resource.

FAQs

What is functional testing?

Functional testing is the process of evaluating an electronic product to ensure it performs its intended functions. It involves various tests to verify the reliability and quality of the product.

Why is functional testing important in the turnkey process?

Functional testing is crucial in the turnkey process as it ensures that the final product meets quality standards and functions as expected. It helps identify and rectify issues before the product reaches the consumer.

How can exporters benefit from functional testing?

Exporters benefit from functional testing by ensuring their products comply with international standards, reducing the risk of recalls, and maintaining a good reputation in the global market.