In today’s fast-paced world of electronics, the demand for complex and compact designs is ever-increasing. Fine pitch PCB assembly in turnkey model has emerged as a vital solution for meeting this demand. This concept plays a crucial role in the electronics manufacturing industry, particularly for exporters and importers who seek efficient and reliable production methods.

What is Fine Pitch PCB Assembly?

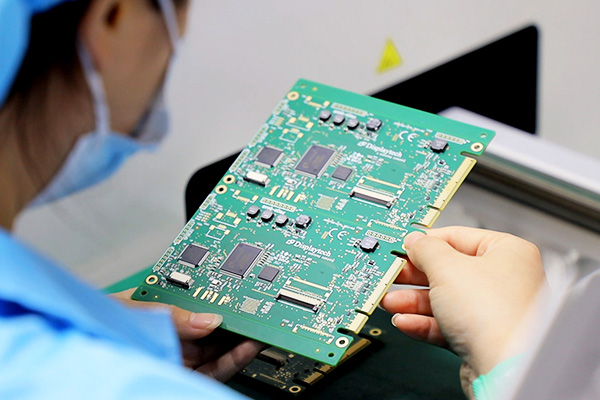

Fine pitch PCB assembly refers to the process of assembling printed circuit boards that have very closely spaced pins or pads. These PCBs are essential for modern electronic devices, which require densely packed components to function efficiently. The precise alignment and connection of these components are critical, making fine pitch PCB assembly a specialized and intricate task.

The Turnkey Model in PCB Assembly

The turnkey model in PCB assembly is an approach where the entire assembly process, from sourcing components to final production, is managed by a single provider. This model offers significant advantages, including reduced production times, cost-efficiency, and improved quality control. By choosing a turnkey provider, companies can focus on other aspects of their business while ensuring a seamless assembly process.

Benefits of a Turnkey Model

- Streamlined Production: The turnkey model integrates all stages of production, reducing the risk of delays and errors.

- Cost-Effective: By handling all aspects of production, turnkey providers can often offer competitive pricing.

- Quality Assurance: With a single provider overseeing the process, quality control measures are more consistent and reliable.

Importance of Fine Pitch PCB Assembly in Turnkey Model

For exporters and importers, the importance of fine pitch PCB assembly in turnkey model cannot be overstated. It allows them to meet the demands of a global market that requires high-quality and reliable electronic components. With the turnkey model, businesses can ensure that their products are manufactured to the highest standards, enhancing their competitiveness and reputation in the industry.

Key Considerations for Exporters and Importers

- Choosing the Right Provider: Selecting a reputable turnkey provider is essential for ensuring quality and efficiency.

- Understanding Market Demands: Exporters and importers must stay informed about global trends and demands to remain competitive.

- Compliance with Regulations: Ensuring that all products meet international standards and regulations is crucial for success.

Challenges in Fine Pitch PCB Assembly

Despite its advantages, fine pitch PCB assembly presents several challenges. The complexity of aligning and soldering closely spaced components requires advanced technology and skilled professionals. Additionally, the risk of defects and errors is higher, necessitating rigorous quality control measures.

Overcoming Challenges

- Advanced Equipment: Utilizing the latest technology and equipment can minimize errors and improve precision.

- Skilled Workforce: Employing experienced technicians ensures that the assembly process is conducted with expertise and accuracy.

- Quality Control: Implementing strict quality control measures can reduce the risk of defects and improve product reliability.

The Future of Fine Pitch PCB Assembly in Turnkey Model

The future of fine pitch PCB assembly in turnkey model looks promising, with advancements in technology and increased demand for compact and efficient electronic devices. As the industry evolves, businesses must adapt to stay ahead of the competition and meet the needs of a global market.

Trends to Watch

- Automation: The use of automation in PCB assembly is expected to increase, improving efficiency and precision.

- Miniaturization: The demand for smaller and more powerful electronic devices will drive the need for fine pitch PCB assembly.

- Sustainability: As environmental concerns grow, the industry will focus on sustainable practices and materials.

Conclusion

In conclusion, fine pitch PCB assembly in turnkey model is a vital component of the electronics manufacturing industry. By understanding its benefits, challenges, and future trends, exporters and importers can make informed decisions and capitalize on the opportunities presented by this innovative approach.

FAQs

- What is fine pitch PCB assembly?

Fine pitch PCB assembly involves assembling PCBs with closely spaced pins or pads, essential for modern electronic devices.

- Why choose a turnkey model?

The turnkey model offers streamlined production, cost-efficiency, and consistent quality assurance, making it an attractive option for businesses.

- What challenges exist in fine pitch PCB assembly?

Challenges include the complexity of aligning components, the risk of defects, and the need for advanced technology and skilled professionals.

For more insights on turnkey PCB assembly, you can visit this article or explore this guide.