In todays fast-paced world, final product assembly turnkey solutions are becoming increasingly vital for both exporters and importers. These solutions offer a streamlined process that encompasses everything from initial planning to the final stages of product delivery. By utilizing these services, companies can significantly enhance their operational efficiency and focus more on their core business strategies.

What are Turnkey Solutions?

Turnkey solutions refer to services that are fully operational and ready for immediate use. In the context of product assembly, these solutions involve the complete handling of the assembly process. From sourcing raw materials to delivering the final product, every step is meticulously managed to ensure top-notch quality and efficiency.

Importance of Turnkey Solutions for Exporters and Importers

The global market is highly competitive, and companies need to adopt strategies that give them an edge. Turnkey solutions allow businesses to reduce costs, minimize risks, and improve product quality. By outsourcing the assembly process, companies can allocate resources more effectively and focus on strategic growth areas.

Benefits of Final Product Assembly Turnkey Solutions

- Cost-Effectiveness: By leveraging economies of scale, turnkey providers can reduce production costs.

- Quality Assurance: With specialized expertise, these providers ensure that only the highest quality standards are met.

- Time Efficiency: Streamlined processes mean faster delivery times, allowing businesses to meet market demands promptly.

Components of a Turnkey Assembly Solution

A comprehensive turnkey assembly solution involves various interconnected components. Each component plays a crucial role in ensuring the success of the overall process.

1. Sourcing of Raw Materials

The first step involves sourcing high-quality raw materials. A reliable turnkey provider will have established relationships with trusted suppliers, ensuring that all materials meet the required specifications.

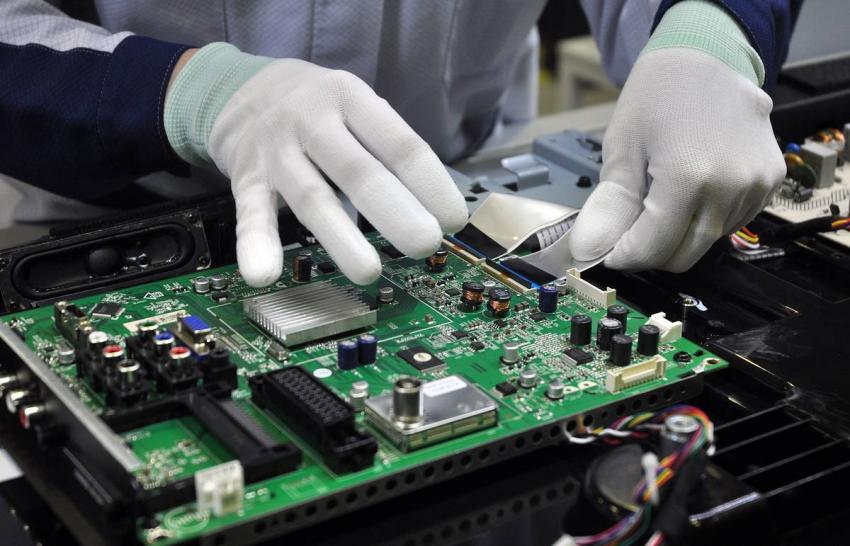

2. Manufacturing and Assembly

The core of the solution lies in the efficient manufacturing and assembly of products. This involves using state-of-the-art technology and skilled labor to produce goods that adhere to strict quality standards.

3. Quality Control and Testing

Quality control is an integral part of any assembly process. Turnkey providers implement rigorous testing procedures to ensure that every product is defect-free and meets the client’s specifications.

4. Packaging and Delivery

Once the products are assembled and tested, they are packaged securely for delivery. Turnkey providers handle logistics to ensure timely and safe delivery to the final destination.

Choosing the Right Turnkey Provider

Selecting the right provider is crucial for the success of a turnkey solution. Here are some factors to consider:

Experience and Expertise

A provider with a proven track record in the industry is more likely to deliver quality results. Evaluate their past projects and client testimonials to gauge their expertise.

Technology and Innovation

Ensure that the provider uses the latest technology and innovative practices in their processes. This not only ensures efficiency but also improves the quality of the final product.

Customer Support

Strong communication and support are essential. Choose a provider that values customer satisfaction and is responsive to your needs.

Challenges in Implementing Turnkey Solutions

While turnkey solutions offer numerous benefits, they also come with challenges. Understanding these challenges can help businesses better prepare and mitigate potential risks.

1. Supply Chain Disruptions

Global supply chain disruptions can impact the timely delivery of raw materials, affecting the overall assembly process. It is essential to have contingency plans in place to manage such disruptions effectively.

2. Quality Control Issues

Ensuring consistent quality across all products can be challenging. Regular audits and quality checks are necessary to maintain high standards.

3. Cost Management

While turnkey solutions can be cost-effective, unexpected expenses can arise. It is crucial to have a transparent pricing model and budget management strategies.

Future of Turnkey Solutions

The future of turnkey solutions looks promising, with advancements in technology and increasing demand for efficient assembly processes. Companies are likely to continue embracing these solutions to stay competitive in the global market.

Embracing Digital Transformation

Digital technologies, such as IoT and AI, are transforming the assembly process. These technologies enable real-time monitoring, predictive maintenance, and enhanced data analytics, improving overall efficiency.

Focus on Sustainability

There is a growing emphasis on sustainable practices in the manufacturing and assembly process. Companies are increasingly adopting eco-friendly materials and processes to reduce their environmental impact.

Conclusion

Final product assembly turnkey solutions offer a comprehensive approach to managing the assembly process, providing numerous benefits to exporters and importers. By understanding the components, benefits, and challenges associated with these solutions, businesses can make informed decisions and achieve greater operational success.

FAQ Section

What are turnkey solutions?

Turnkey solutions are fully operational services that handle all aspects of a process, from start to finish, ready for immediate use.

Why are turnkey solutions important for exporters and importers?

They provide cost-effectiveness, quality assurance, and time efficiency, allowing businesses to focus on strategic growth.

What challenges do businesses face with turnkey solutions?

Challenges include supply chain disruptions, quality control issues, and cost management. Proper planning and management strategies can help mitigate these challenges.