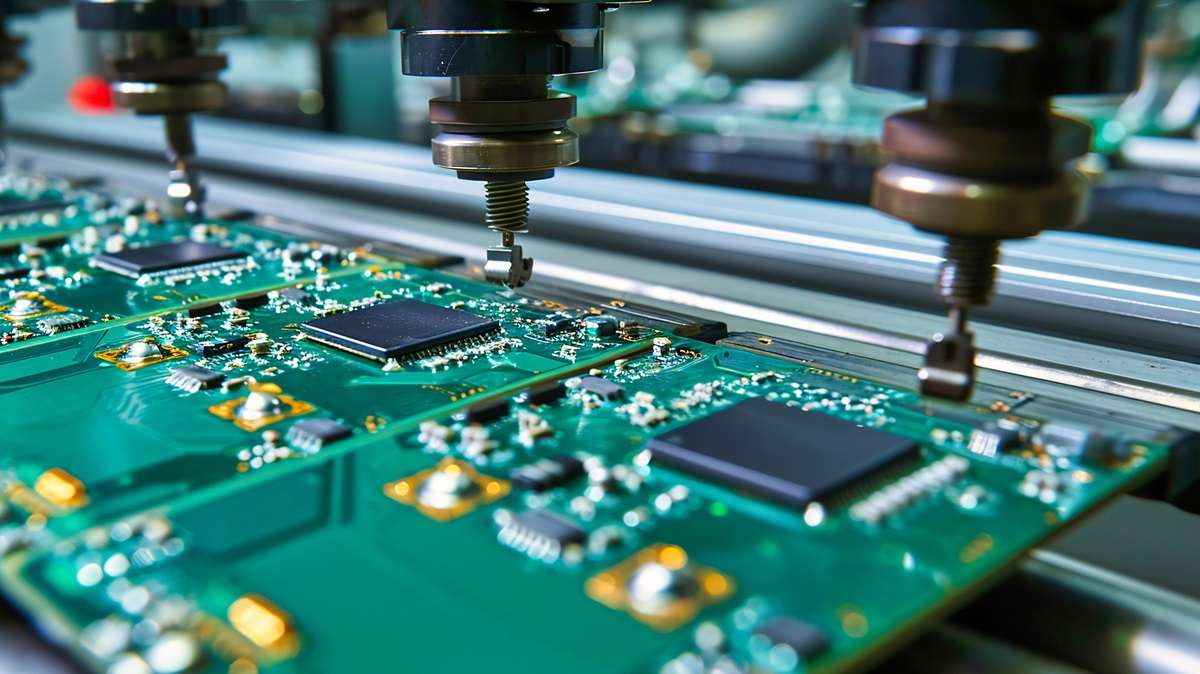

In the world of electronics manufacturing, ESD control in turnkey electronics facilities is pivotal to ensuring product quality and reliability. Electrostatic discharge (ESD) can cause significant damage to electronic components, leading to costly failures and product recalls. As such, implementing effective ESD control measures is critical for facilities engaged in turnkey electronics production.

Introduction to ESD and Its Impact

Electrostatic discharge, commonly known as ESD, is the sudden flow of electricity between two electrically charged objects. This phenomenon can lead to catastrophic failures in sensitive electronic components. In turnkey electronics facilities, where production processes are streamlined for efficiency, ESD poses a significant risk.

Why ESD Control Matters

Controlling ESD is crucial because even a minor discharge can render an electronic component unusable. The financial implications of ESD-related damages can be substantial, impacting not only the manufacturer but also the end-users. Therefore, maintaining strict ESD control protocols is essential for any facility handling electronic assemblies.

Understanding Turnkey Electronics Facilities

A turnkey electronics facility offers comprehensive manufacturing services, from design to production. This model allows clients to outsource their entire production process, ensuring that products are manufactured with precision and care. However, with the convenience of turnkey solutions comes the responsibility of managing ESD risks effectively.

The Role of ESD Control in Turnkey Operations

In turnkey operations, ESD control is integrated into every stage of the production process. From design to assembly, each step is carefully monitored to prevent ESD incidents. This holistic approach ensures that the final product meets the highest quality standards while minimizing the risk of ESD-induced failures.

Key Elements of ESD Control

Implementing ESD control measures requires a comprehensive understanding of various components and strategies. Here are some key elements involved in effective ESD management:

1. ESD-Safe Workstations

Establishing ESD-safe workstations is fundamental to preventing electrostatic discharge. These workstations are equipped with antistatic materials and grounding mechanisms to minimize the risk of static buildup.

2. ESD-Protected Areas (EPAs)

Creating EPAs within the facility is another crucial step. These designated areas are specifically designed to control static electricity and protect sensitive components from potential damage.

3. ESD Training and Awareness

Training employees in ESD awareness and best practices is vital. By educating staff about the risks and prevention strategies, facilities can foster a culture of ESD consciousness and accountability.

Best Practices for ESD Control

Implementing best practices is essential for achieving effective ESD control in turnkey electronics facilities. Here are some proven strategies:

1. Regular Audits and Assessments

Conducting regular audits and assessments ensures that ESD control measures are functioning correctly. These evaluations help identify potential weaknesses and areas for improvement.

2. Continuous Monitoring

Utilizing ESD monitoring equipment allows facilities to continuously track static levels and identify potential issues before they escalate. This proactive approach helps maintain a safe working environment.

3. Proper Grounding Techniques

Implementing proper grounding techniques is critical to dispersing static charges safely. Grounding wrist straps, mats, and equipment are essential components of an effective ESD control program.

Challenges in ESD Control

While implementing ESD control measures is crucial, it is not without challenges. Here are some common obstacles faced by turnkey electronics facilities:

1. Evolving Technology

As technology advances, electronic components become more sensitive to ESD. Keeping up with these changes requires continuous adaptation of ESD control strategies.

2. Cost Considerations

Implementing comprehensive ESD control measures can be costly. However, the long-term benefits of preventing ESD-related damages outweigh the initial investment.

3. Employee Compliance

Ensuring that employees consistently adhere to ESD protocols can be challenging. Regular training and reinforcement of best practices are necessary to maintain compliance.

Conclusion

In conclusion, ESD control in turnkey electronics facilities is an essential aspect of maintaining product quality and reliability. By understanding the risks associated with ESD and implementing effective control measures, facilities can safeguard their operations and deliver high-quality electronic products to their clients.

For more information on turnkey electronics manufacturing and ESD control, visit the BL International Blog.

FAQ Section

1. What is ESD, and why is it important?

ESD, or electrostatic discharge, is the sudden flow of electricity between two charged objects. It is crucial because it can cause damage to sensitive electronic components, leading to product failures.

2. How can facilities prevent ESD incidents?

Facilities can prevent ESD incidents by implementing ESD-safe workstations, creating ESD-protected areas, and providing regular training to employees.

3. What are the challenges of managing ESD in turnkey electronics facilities?

Challenges include keeping up with evolving technology, managing costs, and ensuring employee compliance with ESD protocols.