The world of turnkey PCB assembly is undergoing a remarkable transformation, driven by emerging technologies that are reshaping how businesses approach manufacturing. For exporters and importers in the electronics industry, understanding these developments is crucial to staying competitive and capitalizing on new opportunities.

Understanding Turnkey PCB Assembly

Before diving into the emerging technologies, it is essential to understand what turnkey PCB assembly entails. In simple terms, it refers to a process where the manufacturer handles every aspect of production, from sourcing components to final assembly and testing. This approach allows companies to focus on their core competencies while leaving the complexities of production to experts.

The Role of Technology in PCB Assembly

Technological advancements have always played a significant role in refining turnkey PCB assembly processes. Today, several emerging technologies are taking center stage, promising to enhance efficiency, reduce costs, and improve product quality.

Key Emerging Technologies in Turnkey PCB Assembly

1. Automation and Robotics

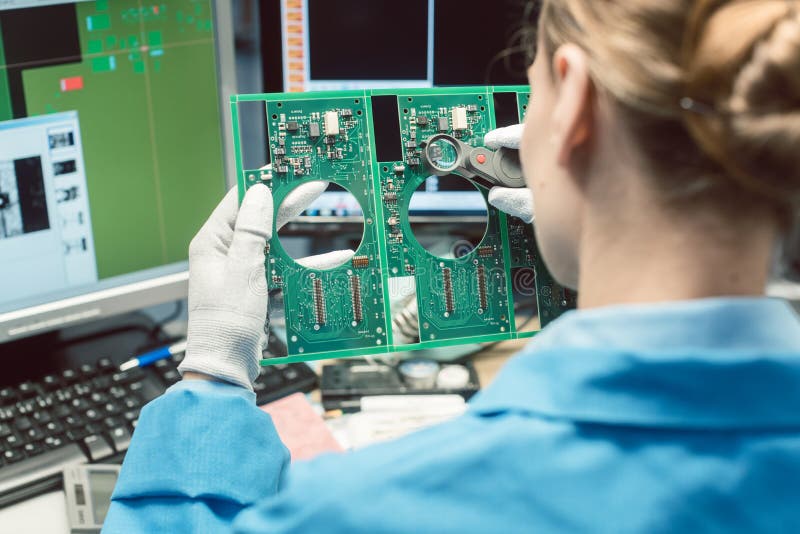

Automation and robotics are transforming turnkey PCB assembly by streamlining processes and reducing human error. Automated systems can handle intricate tasks with precision, from placing components on the board to soldering and inspection.

2. Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing quality control in PCB assembly. These technologies enable predictive maintenance, optimize production schedules, and ensure that every finished product meets high standards.

3. Internet of Things (IoT)

The Internet of Things (IoT) is making its mark on turnkey PCB assembly by enabling real-time monitoring of production lines. IoT devices provide valuable data that helps improve efficiency and reduce downtime.

4. Advanced Materials

New materials are being developed to enhance the performance and durability of PCBs. These materials offer advantages such as better heat dissipation, flexibility, and environmental resistance.

5. 3D Printing

3D printing technology is being integrated into PCB prototyping, allowing for rapid and cost-effective production of custom designs.

Benefits of Emerging Technologies in Turnkey PCB Assembly

Enhanced Efficiency

By adopting emerging technologies, companies can achieve higher levels of efficiency in their manufacturing processes. Automated systems and AI-driven insights enable faster production cycles and reduced waste.

Cost Reduction

Technological innovations in turnkey PCB assembly lead to significant cost savings. Automation reduces labor costs, while AI and IoT optimize resource allocation.

Improved Product Quality

With advancements in quality control through AI and ML, manufacturers can ensure that each product meets stringent quality standards. This results in fewer defects and higher customer satisfaction.

Challenges and Considerations

Integration with Existing Systems

Integrating new technologies with existing manufacturing systems can be challenging. Companies must carefully plan and execute these integrations to avoid disruptions.

Data Security

The increased reliance on IoT and AI raises concerns about data security. Manufacturers must implement robust cybersecurity measures to protect sensitive information.

The Future of Turnkey PCB Assembly

As emerging technologies continue to evolve, the future of turnkey PCB assembly looks promising. We can expect even more automation, smarter systems, and increased connectivity, leading to further improvements in efficiency and product quality.

For those interested in learning more about the benefits and limitations of turnkey electronics manufacturing, you can visit this external resource.

Conclusion

In conclusion, the impact of emerging technologies in turnkey PCB assembly is profound. By embracing automation, AI, IoT, and other innovations, companies can achieve greater efficiency, cost savings, and product quality. Staying informed about these trends is essential for exporters and importers looking to remain competitive in the ever-evolving electronics industry.

FAQs

What are the main benefits of turnkey PCB assembly?

Turnkey PCB assembly offers benefits such as streamlined production, cost savings, and improved product quality through advanced technologies.

How does AI impact PCB assembly?

AI enhances quality control, predictive maintenance, and production optimization, leading to higher efficiency and reduced defects in PCB assembly.

Why is IoT important in manufacturing?

IoT enables real-time monitoring and data collection, improving efficiency and reducing downtime in manufacturing processes.

For further reading, you may find this article on green practices in PCB assembly insightful.