In the dynamic world of electronics, understanding the differences between electronics prototyping vs mass production turnkey is crucial for exporters and importers. These processes serve different purposes, and knowing which one to opt for can significantly impact your business strategy and success.

Understanding Electronics Prototyping

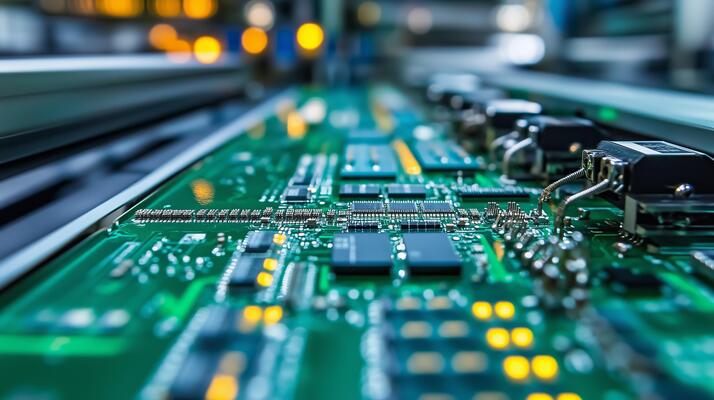

Electronics prototyping is the initial phase in the development of electronic products. It involves creating a preliminary version of a product to test and validate its functionality. During this phase, engineers and designers work together to refine the design, identify potential issues, and enhance the overall product.

Why Choose Prototyping?

Prototyping is essential for ensuring that the final product meets the desired specifications and functions correctly. It allows for early detection of design flaws, which can save time and cost in the long run. Moreover, it provides an opportunity to gather feedback from stakeholders and make necessary adjustments before proceeding to mass production.

Steps in the Prototyping Process

- Concept Development

- Design and Engineering

- Prototype Fabrication

- Testing and Validation

Mass Production Turnkey: An Overview

Once a prototype is successfully tested and validated, the next step is mass production. A turnkey solution in mass production means that the manufacturer handles all aspects of the production process, from sourcing materials to assembling the final product.

Benefits of Turnkey Solutions

Turnkey solutions streamline the production process by offering a single point of contact for all production needs. This approach reduces logistical complexities and allows for better coordination, resulting in faster time-to-market and cost efficiency.

Steps in Turnkey Mass Production

- Material Sourcing

- Production Planning

- Assembly and Testing

- Quality Assurance

- Packaging and Shipping

Key Differences Between Prototyping and Mass Production

The main difference between electronics prototyping vs mass production turnkey lies in their objectives. Prototyping focuses on testing and refining the product, while mass production aims to produce large quantities efficiently and cost-effectively.

- Scale: Prototyping involves small-scale production, whereas mass production involves large-scale manufacturing.

- Cost: Prototyping can be expensive due to the custom nature of the process, while mass production benefits from economies of scale.

- Time: Prototyping can be time-consuming, but it is crucial for ensuring quality and functionality. Mass production is faster and focuses on meeting demand.

Challenges in Electronics Prototyping

Despite its benefits, electronics prototyping poses several challenges:

- High Costs

- Time Constraints

- Complex Design Iterations

Overcoming Challenges in Prototyping

To overcome these challenges, businesses can:

- Utilize Advanced Software Tools

- Collaborate with Experienced Engineers

- Adopt Agile Methodologies

Challenges in Mass Production Turnkey

Mass production also presents its own set of challenges, including:

- Maintaining Quality Standards

- Supply Chain Management

- Meeting Production Deadlines

Strategies for Successful Mass Production

To address these challenges, businesses can:

- Implement Rigorous Quality Control Procedures

- Optimize Supply Chain Processes

- Invest in Reliable Production Technologies

For more insights on turnkey solutions, you can visit Turnkey PCB Assembly. Additionally, explore the concept of Turnkey Contract Manufacturing for a broader understanding.

Conclusion

Choosing between electronics prototyping vs mass production turnkey depends on your business goals and product lifecycle stage. Prototyping is essential for quality assurance and innovation, while mass production is key to meeting market demand efficiently. Understanding these differences and leveraging the right strategies can lead to successful product development and commercialization.

FAQs

What is the main goal of electronics prototyping?

The primary goal of electronics prototyping is to test and refine a product’s design to ensure it meets the intended specifications and functions as expected.

How does turnkey mass production benefit businesses?

Turnkey mass production simplifies the manufacturing process by providing a single point of contact, reducing logistical complexities, and ensuring faster time-to-market.

Why is it important to differentiate between prototyping and mass production?

Understanding the differences helps businesses allocate resources effectively, ensuring quality during prototyping and efficiency during mass production.