The journey from a concept to a finished electronic product involves a series of precise and interconnected processes. Understanding the electronics manufacturing steps is essential for engineers, designers, and business owners who want to bring reliable devices to market. Each phase, from initial design to final testing, plays a crucial role in ensuring quality, functionality, and cost-effectiveness.

Whether you are new to the world of electronics production or looking to optimize your current workflow, gaining insight into these stages can help you make informed decisions. In this guide, we’ll break down the main phases, highlight best practices, and point to further resources for deeper exploration.

For those interested in the details of circuit board creation, you can also learn about the PCB etching process explained to see how raw materials are transformed into the backbone of modern electronics.

Overview of the Electronics Production Lifecycle

The process of manufacturing electronic products typically follows a structured sequence. While specific steps may vary depending on the complexity of the device, most projects include the following core phases:

- Design and prototyping

- Component sourcing

- Printed circuit board (PCB) fabrication

- Assembly (SMT and/or through-hole)

- Soldering and inspection

- Functional testing

- Final assembly and packaging

Let’s take a closer look at each of these electronics manufacturing steps to understand their significance and best practices.

Design and Prototyping: Laying the Foundation

Every successful electronic product starts with a robust design. Engineers use specialized software to create schematics and layout the PCB. This stage involves selecting components, defining electrical connections, and simulating circuit behavior.

Prototyping is the next logical step. By building a small batch of prototypes, designers can validate the concept, identify design flaws, and make necessary adjustments before moving to mass production. This iterative approach reduces costly errors later in the process.

Component Sourcing and Supply Chain Management

Once the design is finalized, the focus shifts to sourcing the required electronic components. Reliable supply chain management ensures that all parts meet quality standards and are available in the needed quantities. Factors such as lead time, cost, and authenticity are carefully considered.

Working with trusted suppliers and maintaining clear documentation helps prevent delays and reduces the risk of counterfeit or substandard parts entering the production line.

PCB Fabrication: Building the Circuit Board

The heart of any electronic device is the printed circuit board. PCB fabrication involves transferring the design onto a physical substrate, etching copper traces, and drilling holes for components. Advanced manufacturing techniques allow for multilayer boards, supporting complex designs and high-density layouts.

Quality control at this stage is vital, as any defects in the board can compromise the entire device. For a deeper dive into board construction, see our resource on understanding PCB layers and their functions.

Assembly Techniques: SMT and Through-Hole Processes

With the PCB ready, components are mounted using either surface-mount technology (SMT), through-hole assembly, or a combination of both. SMT places components directly onto the board’s surface, enabling compact and automated assembly. Through-hole assembly, on the other hand, involves inserting component leads into drilled holes and is often used for parts that require mechanical strength.

Automated pick-and-place machines, reflow ovens, and wave soldering systems streamline this process. To learn more about these techniques, explore our guide on how SMT assembly works in electronics manufacturing, or compare methods in our article on the difference between SMT and through hole assembly.

Soldering and Inspection: Ensuring Reliable Connections

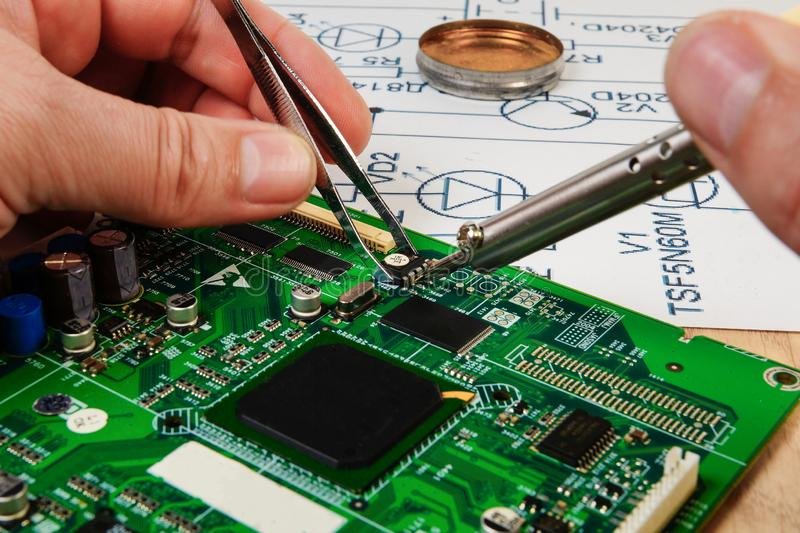

Soldering is the process that electrically and mechanically bonds components to the PCB. Depending on the assembly method, this may involve reflow soldering for SMT parts or wave soldering for through-hole components. Manual soldering is sometimes used for prototypes or specialized assemblies.

Inspection follows soldering to catch any defects such as cold joints, bridges, or misaligned parts. Automated optical inspection (AOI), X-ray analysis, and manual checks are commonly used. For a closer look at joining techniques, see our article on soldering techniques explained.

Functional Testing and Quality Assurance

Before products are shipped, they undergo rigorous testing to verify performance and safety. Functional tests simulate real-world operation, checking for correct voltage levels, signal integrity, and response to user inputs. In-circuit testing (ICT) and boundary scan methods are also employed to detect hidden faults.

Quality assurance protocols ensure that only units meeting all specifications proceed to final assembly. This step is critical for maintaining customer trust and minimizing returns.

Final Assembly, Packaging, and Shipping

The last stage involves assembling the tested boards into their enclosures, adding connectors, displays, or other mechanical parts as needed. Proper packaging protects the finished product during transport and storage. Labels, manuals, and compliance documentation are included to meet regulatory requirements.

Once packaged, products are shipped to distributors, retailers, or directly to customers, completing the manufacturing cycle.

Best Practices for Streamlining Electronics Manufacturing Steps

To ensure efficiency and quality throughout the production process, consider the following recommendations:

- Invest in robust design validation and prototyping to catch issues early.

- Maintain strong relationships with reputable suppliers for reliable component sourcing.

- Implement automated assembly and inspection systems to reduce human error.

- Adopt comprehensive testing protocols to guarantee product reliability.

- Continuously monitor and improve processes based on feedback and data analytics.

For a broader perspective on industry practices, you can review this in-depth overview of the electronics manufacturing process from a global production standpoint.

Frequently Asked Questions

What is the most critical step in electronics manufacturing?

While every phase is important, many experts consider design and prototyping to be the most crucial. Early validation helps prevent costly mistakes and ensures that the final product meets both technical and market requirements.

How do manufacturers ensure the quality of electronic products?

Quality is maintained through a combination of automated inspections, functional testing, and strict adherence to industry standards. Regular audits and continuous improvement initiatives further enhance reliability.

What are the main differences between SMT and through-hole assembly?

SMT (surface-mount technology) places components directly onto the PCB surface, allowing for higher component density and automated assembly. Through-hole assembly involves inserting leads into drilled holes, offering greater mechanical strength but typically requiring more manual labor. For a detailed comparison, see our article on the difference between SMT and through hole assembly.