As electronic devices become more advanced and compact, the importance of following electronic assembly best practices has never been greater. Whether you’re manufacturing printed circuit boards (PCBs) for consumer gadgets or industrial equipment, applying proven methods ensures your products are reliable, safe, and efficient. This guide explores essential steps, quality control measures, and practical tips to help engineers, technicians, and manufacturers achieve consistent results in electronics production.

For those interested in understanding the origins of the components used in assembly, our article on how electronics components are made provides valuable background on the materials and processes involved.

Key Principles for High-Quality Electronics Assembly

Achieving dependable performance in electronic products starts with a solid foundation. The following principles form the backbone of any successful assembly process:

- Component Selection: Always use genuine, high-quality parts from reputable suppliers. Counterfeit or substandard components can compromise device reliability and safety.

- ESD Protection: Electrostatic discharge (ESD) can damage sensitive electronics. Implement ESD-safe workstations, wrist straps, and antistatic mats to protect components throughout handling and assembly.

- Cleanliness: Dust, oils, and residues can cause defects and failures. Maintain a clean workspace and regularly clean PCBs and tools before assembly.

- Documentation: Accurate assembly instructions, schematics, and bills of materials (BOMs) reduce errors and streamline production.

Optimizing PCB Assembly Processes

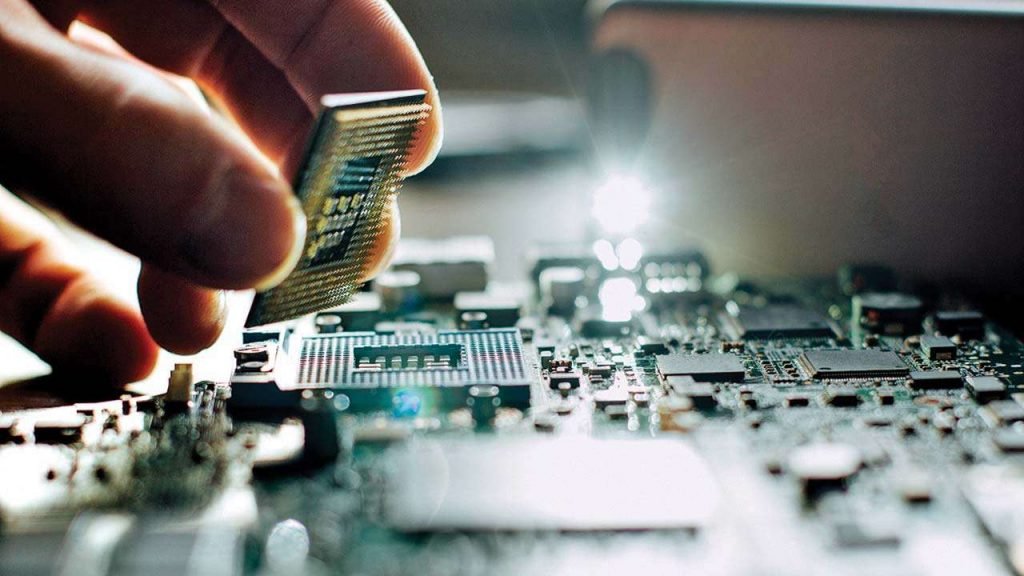

The heart of modern electronics lies in the printed circuit board. Following best practices for PCB assembly is crucial for ensuring product longevity and minimizing rework. Here are several steps to optimize the process:

- Solder Paste Application: Use the correct stencil thickness and ensure even paste distribution. Inconsistent application can lead to solder bridges or cold joints.

- Component Placement: Automated pick-and-place machines offer precision, but manual placement should be double-checked for orientation and alignment.

- Soldering Techniques: Choose between reflow and wave soldering based on component types and board design. For a deeper understanding, see our guide on how wave soldering works.

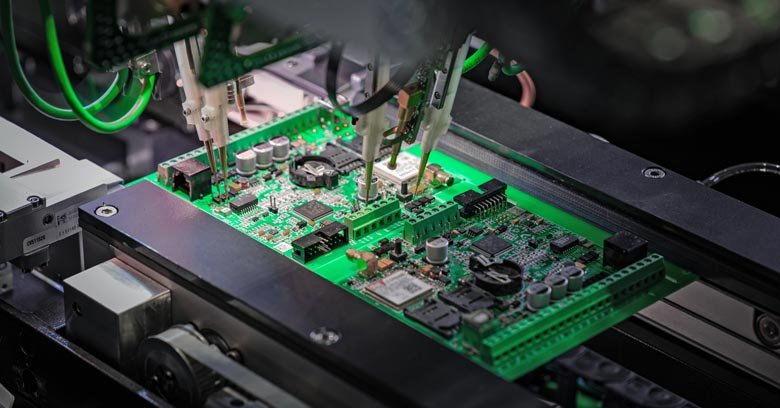

- Inspection: Visual and automated optical inspection (AOI) help catch misalignments, tombstoning, and soldering defects early.

- Testing: Functional and in-circuit tests verify that the assembled board meets design specifications. Explore common approaches in our article on electronics testing methods.

Quality Assurance and Process Control

Consistency in electronics manufacturing is achieved through robust quality assurance (QA) and process control. Here are some proven strategies:

- Standard Operating Procedures (SOPs): Well-documented SOPs ensure every technician follows the same steps, reducing variability.

- Training and Certification: Regular training keeps staff updated on the latest techniques and safety protocols.

- Traceability: Marking boards and components with batch numbers allows for quick identification and recall if issues arise.

- Continuous Improvement: Collect feedback from QA inspections and customer returns to refine processes and prevent recurring problems.

Tools and Materials for Efficient Assembly

Selecting the right tools and materials is a cornerstone of effective electronics production. Some essentials include:

- Soldering Equipment: Adjustable-temperature soldering irons, reflow ovens, and wave soldering machines cater to different assembly needs.

- Inspection Tools: Magnifiers, microscopes, and AOI systems help spot defects that are invisible to the naked eye.

- Prototyping Materials: Breadboards, jumper wires, and test equipment are invaluable for early-stage design. Beginners can benefit from our DIY PCB fabrication guide and our overview of circuit prototyping materials.

- Cleaning Supplies: Isopropyl alcohol, lint-free wipes, and ESD-safe brushes keep assemblies free from contaminants.

Reducing Defects and Improving Yield

Minimizing defects is a top priority in electronics manufacturing. Here are several actionable tips to boost yield and reduce costly rework:

- Design for Manufacturability (DFM): Collaborate with design engineers early to ensure layouts are optimized for assembly.

- Process Monitoring: Use statistical process control (SPC) to track key metrics and identify trends before they become issues.

- Root Cause Analysis: When defects occur, analyze failures thoroughly to address the underlying causes rather than just the symptoms.

- Supplier Quality Management: Work closely with vendors to ensure incoming materials meet your standards.

For a comprehensive overview of the manufacturing process, see this detailed guide to the electronics manufacturing process.

Frequently Asked Questions

What are the most common mistakes in electronics assembly?

Frequent issues include improper soldering (cold joints or bridges), incorrect component placement, inadequate ESD protection, and insufficient inspection. Following established electronic assembly best practices helps prevent these errors and ensures reliable products.

How can I improve the reliability of my assembled boards?

Focus on using quality components, maintaining a clean work environment, applying proper soldering techniques, and implementing thorough testing and inspection. Regular training and adherence to SOPs also play a significant role in boosting reliability.

Why is ESD protection so important in electronics manufacturing?

Electrostatic discharge can instantly damage sensitive semiconductors and integrated circuits, often without visible signs. Implementing ESD-safe workstations, using wrist straps, and handling components carefully are essential steps to prevent latent failures and costly rework.